In Sir Arthur Conon Doyle’s A Scandal in Bohemia, Sherlock Holmes tells Watson, “It is a capital mistake to theorize before one has data. Insensibly one begins to twist facts to suit theories, instead of theories to suit facts.”

In a March 2016 blog post on CCF work breakdown Cimetrix listed eleven points to be taken into consideration when starting an equipment control application using CIMControlFramework (CCF). One of the tasks in the work breakdown is to determine what kind of data collection and storage is to be used in your CCF application and determine how that data is to be stored.

CCF provides several mechanisms for collecting and storing data. These include:

-

History Objects

-

Full GEM Interface

-

Full EDA/Interface A Interface

-

Centralized DataServer

The remainder of this blog post will look at each of these items in more detail.

History Objects

In early iterations of CCF, users noticed when using logging, there were certain messages that they wanted to be able to query without the overhead of having to search all log messages. To help accommodate this need, History objects were introduced. Some examples of these objects in CCF are EPT History, Wafer History and Alarm History. When an important event happens in the life of a history object, a log message is written to a database table (configured during CCF installation) that corresponds to that type of object. That database table can be queried for the specific historical information for only that type of data.

Full GEM/GEM 300 Interface

As described in a CCF blog post from February 15, 2017, CCF comes standard with a fully implemented GEM and GEM 300 interface. The GEM standards allow users to set up trace and event reports for the collection of GEM data. No additional programming is required by the application developer to have access to the GEM data collection.

Full EDA/Interface A Interface

The same blog post of February 15th also states that CCF comes standard with a fully implemented Freeze II and E164 compliant EDA interface. EDA can be used to set up data collection plans based on Events, Exceptions and Traces. With the E157 standard and conditional trace triggers, EDA makes it easy to zero in on the data you want without having to collect all data and then sift through it later.

Centralized DataServer

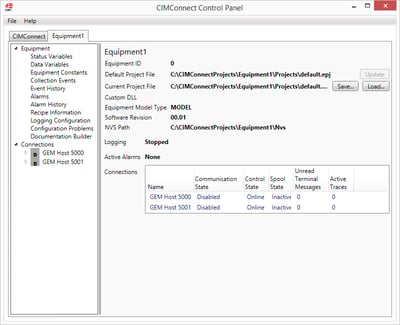

In order to create, initialize, populate and pass data, CCF uses a centralized DataServer object. The DataServer is responsible for creating the dynamic EDA equipment modelas well as populating CIMConnect with Status Variables, Data Variables, Collection Events and Alarms. All this is done at tool startup so that the data available exactly matches the tool that is in use.

Data is routed to the DataServer which then updates the appropriate client – such as EDA, GEM or the Operator Interface. An equipment control application can register to receive an event from the data server when data changes. Users can key off of this event to capture that data and route it to a database as desired. Since all tool manufacturers have different requirements for which database to use and how data is written to that database, CCF leaves the actual SQL (or equivalent) commands for writing the data to the equipment application developer.

With CCF Data collection and storage is … Elementary.

To learn more about CCF, visit the CIMControlFramework page on our website!

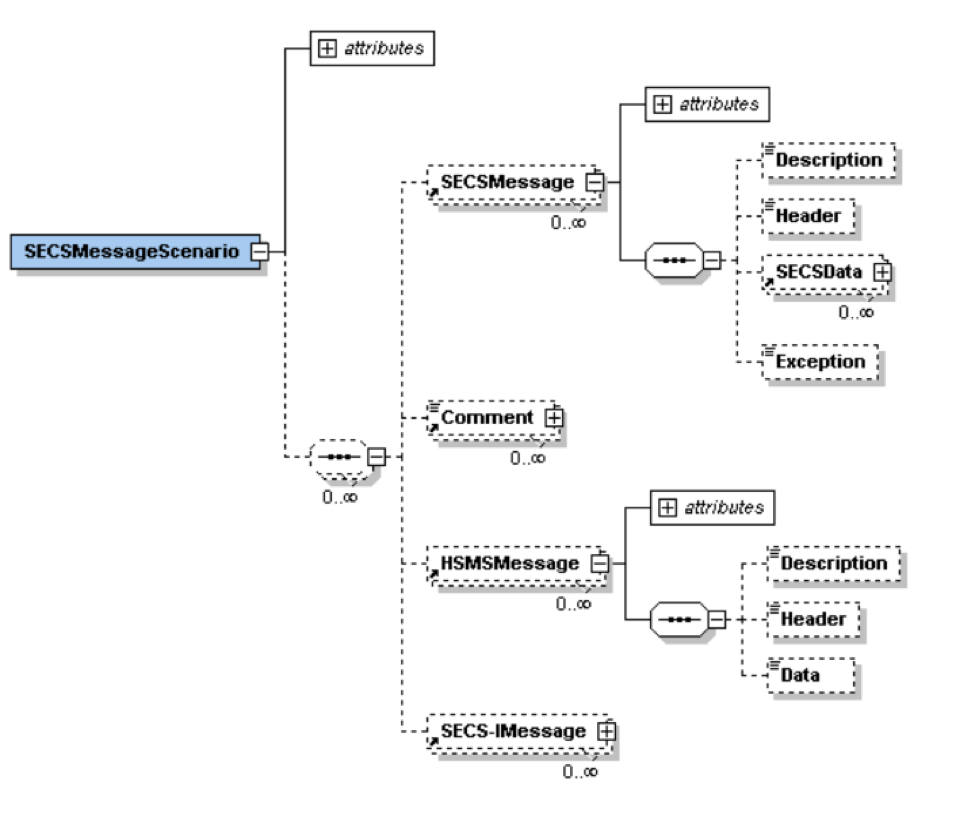

In a previous blog we mentioned that two new SEMI standards, E172 and E173, demonstrated that the GEM standard was alive and well and even gaining new momentum by evolving to adopt new technology. The earlier blog focused on E172 with its SEDD files that use an XML schema to describe what is in a GEM interface. Today’s blog is about the E173 Specification for XML SECS-II Message Notation: a new way to log and document GEM/SECS messages, again using an XML schema.

In a previous blog we mentioned that two new SEMI standards, E172 and E173, demonstrated that the GEM standard was alive and well and even gaining new momentum by evolving to adopt new technology. The earlier blog focused on E172 with its SEDD files that use an XML schema to describe what is in a GEM interface. Today’s blog is about the E173 Specification for XML SECS-II Message Notation: a new way to log and document GEM/SECS messages, again using an XML schema.

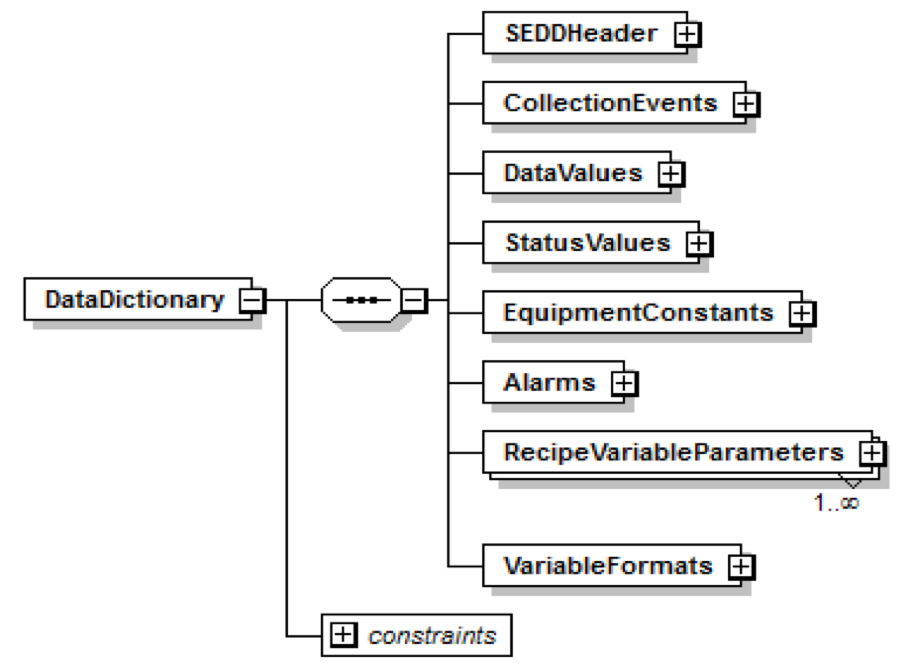

So essentially the SEDD file includes a list of the data available for collection by a host, some general information about the equipment (in the header), and the format of the data variables, status variables and equipment constants. As an example of what details are included, here are the details for collection events.

So essentially the SEDD file includes a list of the data available for collection by a host, some general information about the equipment (in the header), and the format of the data variables, status variables and equipment constants. As an example of what details are included, here are the details for collection events.