It's time to meet the folks that keep Cimetrix running - our Front Office team! Meet Joshua Castro, a Cimetrix Staff Accountant. Read on to learn a little bit more about Joshua.

It's time to meet the folks that keep Cimetrix running - our Front Office team! Meet Joshua Castro, a Cimetrix Staff Accountant. Read on to learn a little bit more about Joshua.

How long have you worked at Cimetrix?

I have worked at Cimetrix for over a year. This is my first job after graduating from the Masters Program at the University of Utah, and I hope to work here for much longer.

What is your role at Cimetrix?

I am a staff accountant here at Cimetrix. For the most part, I process purchase orders from customers and ship Cimetrix software to them. I am also in charge of the company’s payables and employee expense reimbursements using Mineral Tree and Certify. We have a small accounting team here at Cimetrix, so I also help with various accounting projects for the executives.

What drew you to Cimetrix originally?

I found out about the staff accountant position through the University of Utah career website. What drew me in the most was how much they are devoted to finding the right people for the company by conducting a very thorough interview process. It shows that they care for the employees, and want to make sure they find people who are the right fit for the company’s culture. The people are also very friendly, and I could tell that it feels like a family here.

What do you enjoy most about the work you do?

I like being challenged so it is always invigorating when I'm assigned to do new accounting projects. I am not being trained just to perform simple accounting tasks. Rather, the leadership are sculpting me to become a well-rounded accountant. I have been the lead as I've taken on different accounting projects, which allows me to use my accounting skills and knowledge. I feel like the company cares about my growth which encourages me to work even harder.

What do you find to be most challenging about your job?

The most challenging part about my job is juggling between the different accounting functions I am in charge of. This is especially hard during the period of the year when clients tend to send the most puchase orders. It would be easy to get overwhelmed by this, on top of my other accounting duties and deadlines. However, this has taught me to organize and prioritize my tasks so that I can complete them all on time. I keep a checklist of things I need to do for the day and the week. This helps me keep track of things I need to do, and it feels good as I check off each task from my list. These challenges have also taught me to just take a break from my work when I am feeling stressed. I take short walks outside to clear my mind, so that I am reenergized when I return back to my duties.

What are your top 3 favorite books and/or movies?

I don't have a favorite book, but I watch a lot of movies. My top 3 movies are:

- Thank You For Your Service – This is a well-executed movie about what it is like for our military service members who have just returned home from their service. I have two family members who served in the military, and I have gained so much more respect and understanding about what they have done for our country. The movie captures a large range of emotions, and I feel for the characters in the movie.

- A Star is Born – The directing of this movie is so well-done. I have not seen the previous versions of this movie, but this was a great storytelling of Hollywood. The soundtrack is also amazing.

- Four Sisters & A Wedding – This is a Filipino comedy movie about four sisters who are trying to stop their younger brother from marrying a girl they do not like. I like this movie because it has a lot of my Filipino culture in it, and I have dealt with similar things with my own sisters.

What do you like to do in your free time?

I like to spend time with my 6-month old Dalmatian Radar. He used to be in a military bomb-sniffing program before we got him, but the owners decided that that was not the right route for him. We bought him from the military and are training him to become a service dog specifically for PTSD. He is currently in puppy school, and I’m also training him to do different tricks and commands. I also like to hike and travel so we usually do trips in our trailer to different hiking spots. The most recent hike is at Zion National Park where we did Angels Landing. It was a long hike but I safely crawled my way up to the top. Lastly, I play video games on my free time. I enjoy the game Overwatch, which is a fun team-based game with different characters and abilities.

I like to spend time with my 6-month old Dalmatian Radar. He used to be in a military bomb-sniffing program before we got him, but the owners decided that that was not the right route for him. We bought him from the military and are training him to become a service dog specifically for PTSD. He is currently in puppy school, and I’m also training him to do different tricks and commands. I also like to hike and travel so we usually do trips in our trailer to different hiking spots. The most recent hike is at Zion National Park where we did Angels Landing. It was a long hike but I safely crawled my way up to the top. Lastly, I play video games on my free time. I enjoy the game Overwatch, which is a fun team-based game with different characters and abilities.

Cimetrix held its annual shareholder meeting this past Friday, August 16, 2019 at our headquarters in Salt Lake City, UT. It was nice to see many familiar faces as well as some new faces. There was just one proposal voted on at the meeting to re-elect all five Directors, which was approved by shareholders with over 99% of the votes cast in favor of the proposal. Bob Reback, our President and CEO, introduced each member of Board of Directors and provided a brief history of each board member’s tenure with Cimetrix and the specific expertise and value each of them bring to Cimetrix and our shareholders. We appreciate the wisdom, hard work and direction from our talented board members as well as their commitment to fairly represent the interests of shareholders. We are thankful to our shareholders for their continued support of Management and our Board of Directors.

Cimetrix held its annual shareholder meeting this past Friday, August 16, 2019 at our headquarters in Salt Lake City, UT. It was nice to see many familiar faces as well as some new faces. There was just one proposal voted on at the meeting to re-elect all five Directors, which was approved by shareholders with over 99% of the votes cast in favor of the proposal. Bob Reback, our President and CEO, introduced each member of Board of Directors and provided a brief history of each board member’s tenure with Cimetrix and the specific expertise and value each of them bring to Cimetrix and our shareholders. We appreciate the wisdom, hard work and direction from our talented board members as well as their commitment to fairly represent the interests of shareholders. We are thankful to our shareholders for their continued support of Management and our Board of Directors.

There are some of us in the software development community who recall when cloud computing was not much more than a marketing buzzword, mocked by many developers with first-hand experience at the pace of change in the internet age, but maybe not quite enough experience to know better. Today, cloud-enabled architectures are so commonplace that it’s the alternatives that must be defended in most quarters. Although not necessarily in manufacturing.

There are some of us in the software development community who recall when cloud computing was not much more than a marketing buzzword, mocked by many developers with first-hand experience at the pace of change in the internet age, but maybe not quite enough experience to know better. Today, cloud-enabled architectures are so commonplace that it’s the alternatives that must be defended in most quarters. Although not necessarily in manufacturing. At Cimetrix we have some experience working with manufacturers who are stepping into this area of I4.0 / cloud confluence. Our sense is that the conversations occur along the similar lines of pursuit. The first topics of conversation revolve around fear – security being the chief concern. How can a factory allow its data to leave the four walls? Two recent events have made this argument easier to overcome: TSMC had to shut down a major part of its operations in the summer of 2018 when a computer virus, installed on a new tool, spread to many other hosts. Hundreds of millions of dollars in shipment delays and other costs resulted from a breach of what had previously been thought to be a secure factory environment. On the cloud side: The Capital One breach, where one million social security numbers were stolen, had initial headlines that related it to the Amazon cloud. Since then, the bank has admitted fault and it has become clear that AWS services are secure.

At Cimetrix we have some experience working with manufacturers who are stepping into this area of I4.0 / cloud confluence. Our sense is that the conversations occur along the similar lines of pursuit. The first topics of conversation revolve around fear – security being the chief concern. How can a factory allow its data to leave the four walls? Two recent events have made this argument easier to overcome: TSMC had to shut down a major part of its operations in the summer of 2018 when a computer virus, installed on a new tool, spread to many other hosts. Hundreds of millions of dollars in shipment delays and other costs resulted from a breach of what had previously been thought to be a secure factory environment. On the cloud side: The Capital One breach, where one million social security numbers were stolen, had initial headlines that related it to the Amazon cloud. Since then, the bank has admitted fault and it has become clear that AWS services are secure. Once these fears are assuaged the next line of reasoning tends towards identifying opportunities. This is where Cimetrix is uniquely positioned. We have the expertise to connect factory equipment, get the data into the cloud, and show our customers how to begin exploiting these technologies. Very often the first step is simply to connect as much factory equipment as possible, get a few simple messages, and expand later. This option has proven very fruitful for distributed supply chains that utilize contract manufacturing and outsourcing. Knowing the rate at which equipment is being utilized, which can be done with as few as two simple messages, can be extremely useful. Negotiating capital budgets for new products tends to improve when utilization rates for existing equipment are well known to all parties. The ROI for projects like this tends to be of the scale of months or weeks, not years.

Once these fears are assuaged the next line of reasoning tends towards identifying opportunities. This is where Cimetrix is uniquely positioned. We have the expertise to connect factory equipment, get the data into the cloud, and show our customers how to begin exploiting these technologies. Very often the first step is simply to connect as much factory equipment as possible, get a few simple messages, and expand later. This option has proven very fruitful for distributed supply chains that utilize contract manufacturing and outsourcing. Knowing the rate at which equipment is being utilized, which can be done with as few as two simple messages, can be extremely useful. Negotiating capital budgets for new products tends to improve when utilization rates for existing equipment are well known to all parties. The ROI for projects like this tends to be of the scale of months or weeks, not years.

The Cimetrix Resource Center is a great way to familiarize yourself with standards within the industry as well as find out about new and exciting technologies.

The Cimetrix Resource Center is a great way to familiarize yourself with standards within the industry as well as find out about new and exciting technologies.

The old adage “You get what you pay for” doesn’t fully apply to equipment automation interfaces… more accurately, you get what you require, and then what you pay for!

The old adage “You get what you pay for” doesn’t fully apply to equipment automation interfaces… more accurately, you get what you require, and then what you pay for!

It's time to meet the folks that keep Cimetrix running - our Front Office team! Meet Jake Strong, Cimetrix Controller

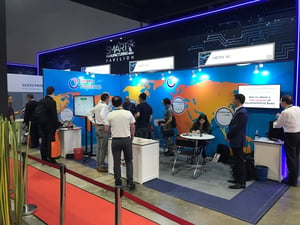

It's time to meet the folks that keep Cimetrix running - our Front Office team! Meet Jake Strong, Cimetrix Controller Our booth was extremely busy the whole time with demonstrations of Sapience and EquipmentTest. We gave out vouchers for free copies of

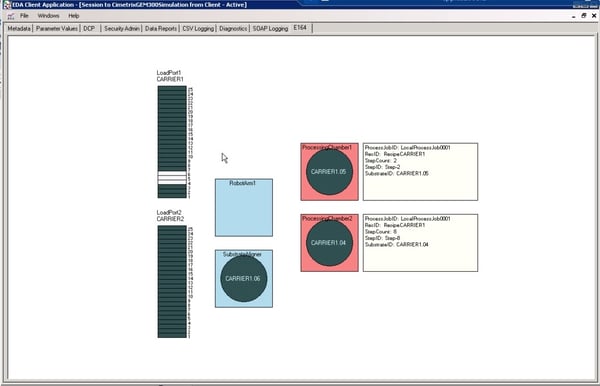

Our booth was extremely busy the whole time with demonstrations of Sapience and EquipmentTest. We gave out vouchers for free copies of  Here is Mike and Jesse giving a demonstration to a tour group. The equipment is located right behind the crowd for all to see; with Sapience displaying data and the crowd taking pictures. SEMI did a great job organizing this. We had top government officials, factories, equipment manufacturers, electronics distributors and universities come through the tours. We also exceeded expectations by adding artificial intelligence to the demonstration. Amazon Alexa was integrated into Sapience which allowed us to ask Alexa which factory was most productive last week. Alexa and Sapience analyzed the data and gave the answer to the tour crowd.

Here is Mike and Jesse giving a demonstration to a tour group. The equipment is located right behind the crowd for all to see; with Sapience displaying data and the crowd taking pictures. SEMI did a great job organizing this. We had top government officials, factories, equipment manufacturers, electronics distributors and universities come through the tours. We also exceeded expectations by adding artificial intelligence to the demonstration. Amazon Alexa was integrated into Sapience which allowed us to ask Alexa which factory was most productive last week. Alexa and Sapience analyzed the data and gave the answer to the tour crowd.