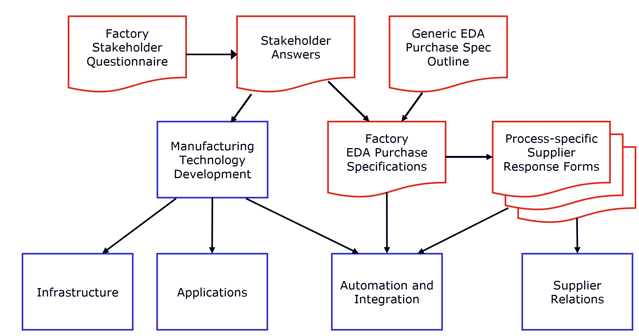

In the introduction to this series (posted December 19, 2017), we listed some of the manufacturing stakeholders whose work objectives are directly addressed by the applications we’ll highlight in this and subsequent postings. In the second article, we explained the process used to map the careabouts of key stakeholder groups into specific EDA interface requirements which are can then be directly included in the purchasing specifications.

In this post, we’ll explain how some of those interface requirements support an important factory application that has general applicability across all equipment types, namely “real-time throughput monitoring.” This application can realistically work with a variety of equipment types with no custom code or configuration depending, of course, on how faithfully the equipment supplier implements the SEMI standards referenced in the requirements specification. This powerful concept greatly improves the software engineering productivity of a fab’s automation team, so we’ll take some time to explain how this is possible.

Problem Statement

This application addresses the problem of monitoring equipment throughput performance in real time, and raising an alarm when it drifts away from “normal” for any reason. This is especially important for bottleneck equipment (e.g., litho tracks and scanners), because any loss of throughput ripples throughout the line, resulting in lost production and its associated revenue and profit. Stated simply, “lost time on a bottleneck tool can never be recovered.”

Solution Components

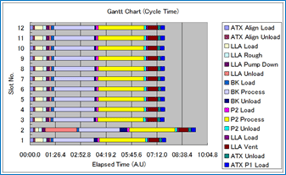

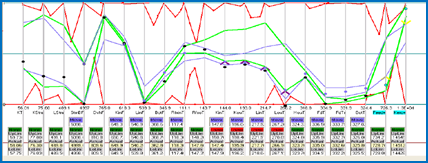

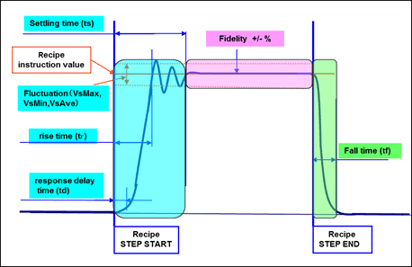

This application requires data that includes primarily the equipment events that chronicle the movement of substrates through the equipment and execution of the recipes appropriate for this equipment type (process, metrology, inspection, sorting, etc.). With this information, the application calculates the process time “on the fly” and compares the current value with the expected (“normal”) value.

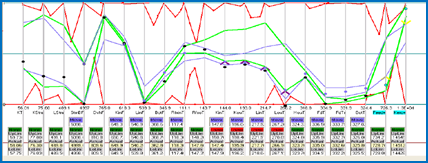

This is not as simple as it first may seem, because the expected value will likely depend on the product type, process type, material status, layer, recipe, and several other factors. Taken together, the set of factors that determines “equivalence” of different lots for some processing purpose is called “context.” For this application, the context parameters ensure that you are comparing apples and apples when looking for variations in process time.

EDA (Equipment Data Acquisition) Standards Leverage

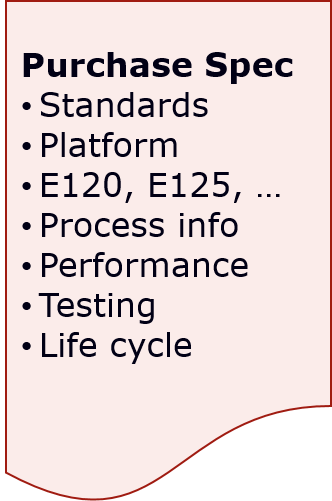

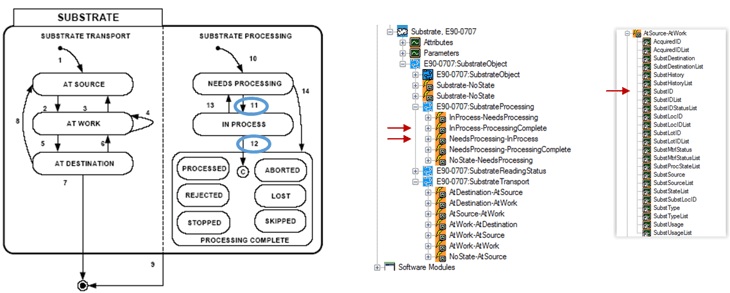

By “EDA,” we include not only the standards in the Freeze II / 0710 suite, but also SEMI E164 (EDA Common Metadata), E157 (Module Process Tracking), and by reference, the entire GEM 300 suite. This ensures not only the granularity and breadth of event support necessary to precisely track wafer movement and step-level recipe execution, but also specifies the naming conventions of those events and their associated parameters, regardless of equipment type or vendor.

If the equipment automation purchase specifications include clauses that state “we require that all state machines, states, state transition events, and attributes of the objects defined in the referenced 300mm SEMI standards be implemented and named exactly as specified in the standards,” then all the information you should need to write a truly generic throughput monitoring application will be available on demand.

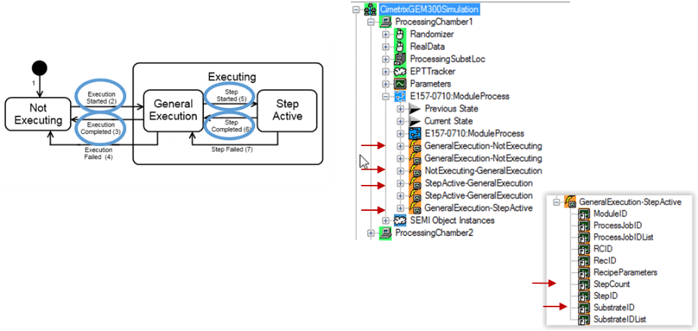

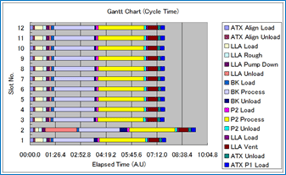

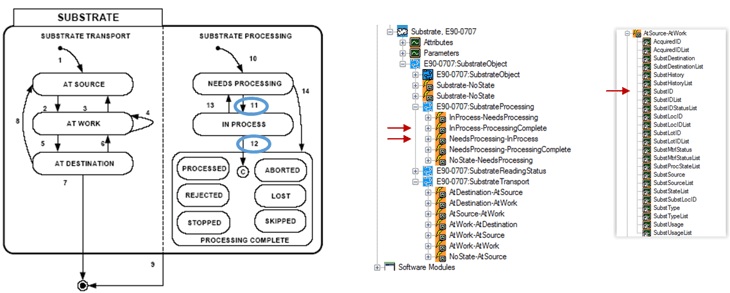

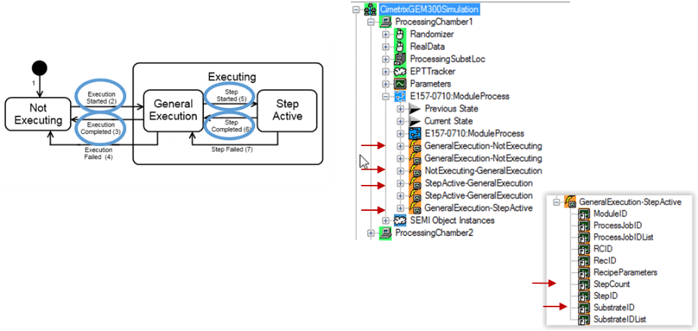

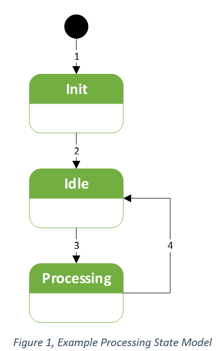

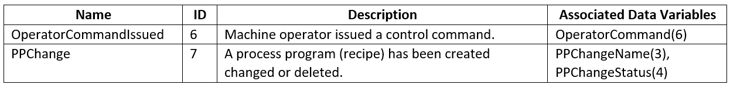

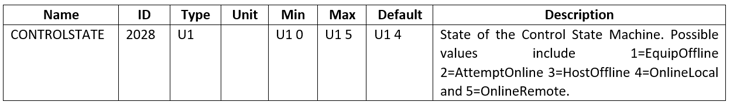

A robust real-time throughput monitoring algorithm can be implemented with information solely from the following SEMI standards: E90 (Substrate Tracking), E157 (Module Process Tracking), E40 / E94 (Processing / Control Job Management), and E87 (Carrier Management). The Harel state diagrams, events of interest, and EDA metadata model representation* for a couple of these (E90 and E157) are shown in the figures below.

Note that as little or as much of the parameter information required to be available for each event (the rightmost picture in each figure) can be collected via the EDA construct of a “Data Collection Plan” (DCP) with one or more “Event Requests.” For more information about these capabilities, consult the SEMI E134 (Data Collection Management) specifications directly, or review some of the extensive educational material available on our web site.

The other point of leverage for the EDA standards is the multi-client capability. This contributes to the productivity and responsiveness of your automation software team members by allowing them to collect and process the data for this application independently from any other application. Specifically, the throughput monitoring functions can be implemented separately from whatever systems host the GEM command and control capabilities, which are usually managed very carefully because of their potentially negative impact on fab operations.

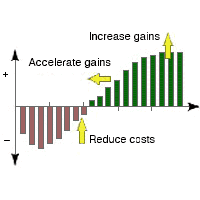

Key ROI Factors

As we said in the initial post of this series, this application is not just something you could build and deploy with EDA-enabled equipment… in fact, this has already been done, and is delivering real production manufacturing benefit! Specifically, the ROI factors impacted (and benefit delivered) by this application include productivity excursion mean-time-to-detect (MTTD, 50% reduction), selected equipment throughput improvement (3-5%), and overall cycle time reduction (difficult to quantify precisely because of the staged implementation process).

As we said in the initial post of this series, this application is not just something you could build and deploy with EDA-enabled equipment… in fact, this has already been done, and is delivering real production manufacturing benefit! Specifically, the ROI factors impacted (and benefit delivered) by this application include productivity excursion mean-time-to-detect (MTTD, 50% reduction), selected equipment throughput improvement (3-5%), and overall cycle time reduction (difficult to quantify precisely because of the staged implementation process).

Of course, these results will vary depending on the manufacturer’s fab loading, operations strategy, and overall automation capabilities, but are representative for leading edge production wafer fabs running at near capacity. However, since these are very common ROI factors, most companies can easily quantify these improvements in real financial terms.

In Closing...

As always, your feedback is welcome, and we look forward to sharing the Smart Manufacturing journey with you.

*The visualizations of equipment metadata model fragments are those produced by the Cimetrix ECCE Plus product (Equipment Client Connection Emulator).

Let us know if you would like to schedule a meeting to learn more:

![]() SEMICON West 2018 is fast approaching and the Cimetrix team is gearing up for a great show. The show runs from July 10th – 12th at the Moscone Center in San Francisco and we’re looking forward to meeting with all our present and future clients.

SEMICON West 2018 is fast approaching and the Cimetrix team is gearing up for a great show. The show runs from July 10th – 12th at the Moscone Center in San Francisco and we’re looking forward to meeting with all our present and future clients.

I remember as a new Boy Scout, we planned a hiking trip up into a primitive area in the mountains near my home. One of the first things we learned about reading a map was where to find the legend. The map legend contains important information needed to read a map, like indicating which direction is north. Now that we knew where to find the legend, we could orient the map so it made sense as we were planning our hike.

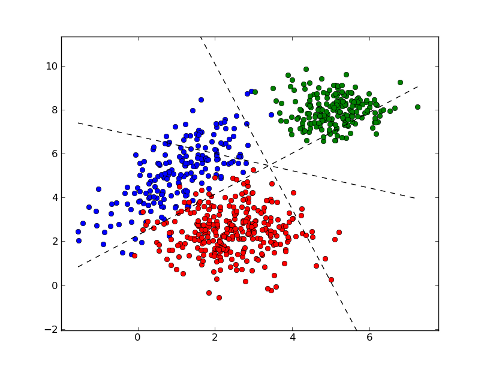

I remember as a new Boy Scout, we planned a hiking trip up into a primitive area in the mountains near my home. One of the first things we learned about reading a map was where to find the legend. The map legend contains important information needed to read a map, like indicating which direction is north. Now that we knew where to find the legend, we could orient the map so it made sense as we were planning our hike. The other major solution component for a production FDC system is a fault model library management capability that can handle large numbers of models. This is necessary because the multivariate approach includes little or no awareness of the physical meaning of the principal components (i.e., they are not “first principles” based), so different operating points for the equipment must have their own sets of fault models. The proper models for a given operating point are selected by matching the values of the “context parameters” for a specific run to those used to store the models. Even if some models can be shared across a range of operating points, the number of distinct models for a foundry megafab will still number in the thousands.

The other major solution component for a production FDC system is a fault model library management capability that can handle large numbers of models. This is necessary because the multivariate approach includes little or no awareness of the physical meaning of the principal components (i.e., they are not “first principles” based), so different operating points for the equipment must have their own sets of fault models. The proper models for a given operating point are selected by matching the values of the “context parameters” for a specific run to those used to store the models. Even if some models can be shared across a range of operating points, the number of distinct models for a foundry megafab will still number in the thousands.

SEMICON China was held from March 14-16, 2018 in Shanghai at the Shanghai New International Expo Centre. Simultaneously co-located at this huge complex were Productronica China and Laser World of Photonics China. All three shows were very busy this year, and it is clear the electronics manufacturing industry in China is booming.

SEMICON China was held from March 14-16, 2018 in Shanghai at the Shanghai New International Expo Centre. Simultaneously co-located at this huge complex were Productronica China and Laser World of Photonics China. All three shows were very busy this year, and it is clear the electronics manufacturing industry in China is booming.

As the

As the

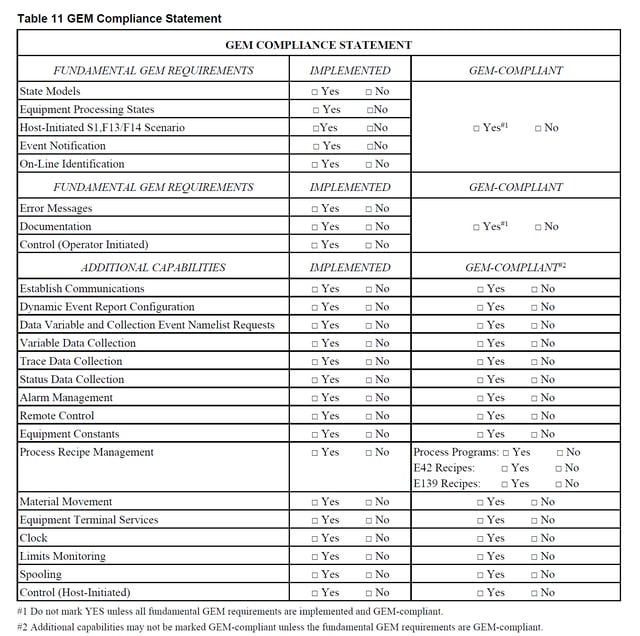

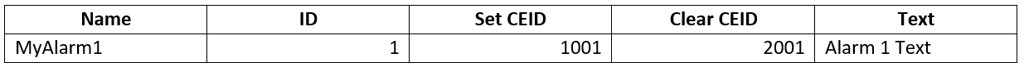

Just like a home alarm system, semiconductor fabs want to know when something bad has happened. They want to prevent the material being processed from being scrapped. Alarm management enables the equipment to notify the host when something goes wrong, and provide information about what has gone wrong. The GEM standard defines Alarm Management as the capability to provide host notification and management of alarm conditions occurring on the equipment.

Just like a home alarm system, semiconductor fabs want to know when something bad has happened. They want to prevent the material being processed from being scrapped. Alarm management enables the equipment to notify the host when something goes wrong, and provide information about what has gone wrong. The GEM standard defines Alarm Management as the capability to provide host notification and management of alarm conditions occurring on the equipment.  condition occurs. Communicating that additional information to the host is valuable, but cannot be done through the normal Alarm Report Send/Acknowledge messages. To provide a way to get this additional information, GEM requires that two collection events be defined for each possible alarm condition on the equipment – one event for when the alarm is set, and another for when the alarm is cleared. These collection events allow the GEM event data collection mechanisms to be used to send the additional related information to the host when an alarm changes state.

condition occurs. Communicating that additional information to the host is valuable, but cannot be done through the normal Alarm Report Send/Acknowledge messages. To provide a way to get this additional information, GEM requires that two collection events be defined for each possible alarm condition on the equipment – one event for when the alarm is set, and another for when the alarm is cleared. These collection events allow the GEM event data collection mechanisms to be used to send the additional related information to the host when an alarm changes state.