Background

At SEMI in North America, the Information & Control Committee meets three times per year; spring summer and fall. This year the summer meetings were held on July 10, 11 and 13 in conjunction with SEMICON West is San Francisco, CA. The meetings include task forces with leaders from Cimetrix on the GEM 300, ABFI (Advanced Backend Factory Integration), GUI, DDA, CDS task forces as well as the committee meeting on the final day which was held on Thursday instead of the typical Wednesday. This is a summary of what happened in the task forces I am highly involved in including GEM 300, ABFI and DDA as well as some updates from SEMI.

Note that all ballots that pass are still subject to a final review by the global SEMI Audit & Review committee, where a ballot can still fail when proper SEMI procedures and regulations were not strictly followed.

SEMI

A few changes are happening at SEMI. SEMI is planning to start publishing ‘red-line’ versions of the SEMI standards. Today, when a new version of a SEMI standard is published, it includes change bars on the side to indicate where changes have occurred. The changed section can then be compared with the previous publication to see what changed. While this is helpful to readers, the planned ‘red-line’ versions will identify precise changes using redline strikethrough and underlining to identify the changes. This is a big benefit to the standards community. I look forward to seeing this new feature.

SEMI is planning to add additional digital enforcement to the SEMI standard documents to help enforce SEMI’s copyright to the standards. This should help curb some of the copyright abuse. Every company implementing or using the SEMI standards should have at least one subscription to SEMIViews, https://www.semiviews.org/.

SEMI has hired another technical writer to help keep SEMI standard publication up to date. Recently, the growing queue of standards awaiting publication has affected SEMI standards development. For example, this has caused delays in the DDA task force developing EDA Freeze 3. In the last 9 months, SEMI has already reduced the publication queue substantially and is committed to catching up early in 2024.

GEM 300 Task Force

A lot is going on the GEM 300 task force.

Ballot 7065, an update to the SEMI E172 passed nearly super-clean. SEMI E172, SPECIFICATION FOR SECS EQUIPMENT DATA DICTIONARY (SEDD) defines the XML schema for documenting a GEM interface. Recently the GEM standard was updated to allow transfer of a SEDD file through the GEM interface using Stream 21 messages. Ballot 7065 adds a few new features and changes to the schema files. The most important changes are names for alarms and a ‘well-known’ element to all collection events, variables, and alarms. This ‘well-known’ element is meant to contain a standardized alias so that end users can automatically map an implementation to required items in the SEMI standards. To capitalize on the new E172 ‘well-known’ feature, new ballots were approved to modify E5/E30, E40, E87, E90, E94, E116 and E157 to include standardized ‘well known’ names. These ballots are expected to be completed in time for cycle 7 voting this year.

Ballot 7066 proposed changes to the SEMI E87 Carrier Management Services (CMS) standard. This included a significant change to the new Carrier Ready to Unload Prediction feature. The primary driver for this change is to accommodate internal buffer equipment where the READY TO UNLOAD state depends on when the host sends a CarrierOut message and can be drastically impacted by the carrier-out queue. The ballot proposes to use CARRIER COMPLETE prediction instead, which can be universally applied both fixed buffer and internal buffer equipment. The change has little impact on fixed buffer equipment, where the time between CARRIER COMPLETE and READY TO UNLOAD is typically short and a fixed time. Unfortunately, this line item in the ballot needs some rework before it is ready for acceptance.

The other line items in ballot 7066 passed including a clarification to the ContentMap behavior and an update to the CMS compliance statement. Two requirements related to the ContentMap were in contradiction to each other affecting the ContentMap value when a carrier object is instantiated. The clarification allows the ContentMap to either be an empty list or a structured list of empty lot and substrate ID information. The change only affects the initial value. The compliance statement change adds the missing “Access Mode State Model” to the compliance statement so implementers can declare whether this feature is implemented and compliant.

Ballot 6991 also passed as super-clean (no negative votes) to update SEMI E4 SEMI Equipment Communications Standard 1 Message Transfer (SECS-I). The update removes biased terminology to be compliant with recently updated SEMI regulations. No technical changes were made.

ABFI (Advanced Backend Factory Integration) Task Force

New proposed standards for Consumables and Durables (ballots 6924A and 6925A) both will require Ratification ballots. This means that a few technical changes need to be made for the new standards to be accepted. Ratification ballots R6924A and R6925A will be submitted in the next voting cycle with those technical changes. If this passes, then the new standards will be published. If it fails, then the ballots will be reworked for another voting cycle.

DDA (Diagnostics Data Acquisition) Task Force

The DDA task force meeting was relatively quiet and uneventful for the first time in years while the task force waits for accepted ballots to be published including updates to E125/E125.2, E134/E134.2, and E120.2. No ballots were adjudicated. Ratification ballot R7002 for SEMI standards E132 and E132.2 passed in the voting cycle 4. Meanwhile new versions of E121 and E179 were published by SEMI in April and June, respectively.

Next steps for the DDA task force include updating E164 and planning a ‘vendor test session’. The E164 update is tied to the GEM 300 ‘well-known’ feature mentioned above, where the E164 names and IDs will be synchronized with the aliases added to the GEM 300 standards. The vendor test session is planned to occur during Spring 2024. Any company wishing to participate to validate EDA client or server software against other implementations is welcome. Participants will run through a small set of E132 scenarios, E125 scenarios and E134 scenarios to validate the current standards. Any issues found during this testing will be quickly resolved so that an EDA freeze 3 version can finally be declared. The task force leaders plan to share a test plan before Fall meetings to help everyone prepare.

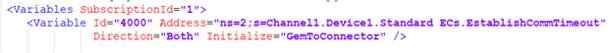

This example links the GEM EstablishCommTimeout equipment constant (VID = 4000) to an OPC UA tag = “Channel1.Device1.Standard ECs.EstablishCommTimeout”. Since equipment constants can be updated by the operator or by the host, the Direction attribute is “Both”.

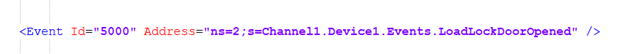

This example links the GEM EstablishCommTimeout equipment constant (VID = 4000) to an OPC UA tag = “Channel1.Device1.Standard ECs.EstablishCommTimeout”. Since equipment constants can be updated by the operator or by the host, the Direction attribute is “Both”. This example links a GEM collection event (CEID = 5000) to a Boolean OPC UA tag = “Channel1.Device1.Events.LoadLockDoorOpened”. The GEM OPC Connector monitors this tag for any value changes, and when the value changes from 0 to 1, it calls a method in CIMConnect to trigger the associated event.

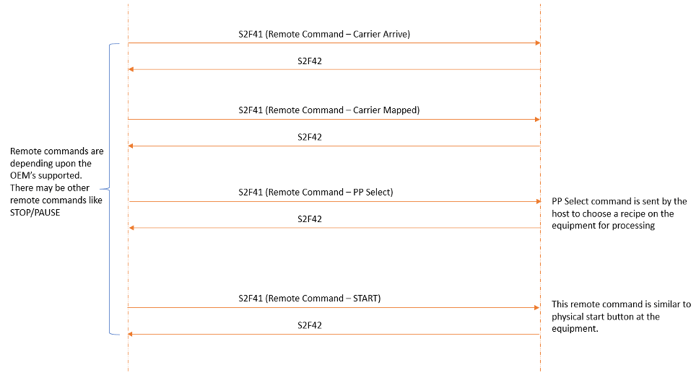

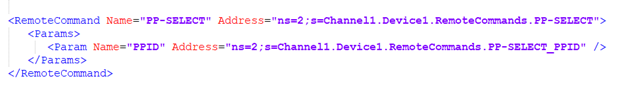

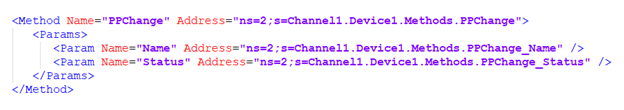

This example links a GEM collection event (CEID = 5000) to a Boolean OPC UA tag = “Channel1.Device1.Events.LoadLockDoorOpened”. The GEM OPC Connector monitors this tag for any value changes, and when the value changes from 0 to 1, it calls a method in CIMConnect to trigger the associated event. This example links the GEM “PP-SELECT” remote command to the Boolean OPC UA Tag = “Channel1.Device1.RemoteCommands.PP-SELECT”. Parameter values are optional. In this case there is a single parameter linked to OPC UA tag = “Channel1.Device1.RemoteCommands.PP-SELECT_PPID”. When the host sends the PP-SELECT remote command using S2F41 “Host Command Send”, the GEM OPC Connector handles the message as follows: if the value of the Processing State is such that the equipment can accept this remote command, the parameter value will be updated first, and then the PP-SELECT value will be set to ”True” to notify the PLC application that the remote command was invoked.

This example links the GEM “PP-SELECT” remote command to the Boolean OPC UA Tag = “Channel1.Device1.RemoteCommands.PP-SELECT”. Parameter values are optional. In this case there is a single parameter linked to OPC UA tag = “Channel1.Device1.RemoteCommands.PP-SELECT_PPID”. When the host sends the PP-SELECT remote command using S2F41 “Host Command Send”, the GEM OPC Connector handles the message as follows: if the value of the Processing State is such that the equipment can accept this remote command, the parameter value will be updated first, and then the PP-SELECT value will be set to ”True” to notify the PLC application that the remote command was invoked.

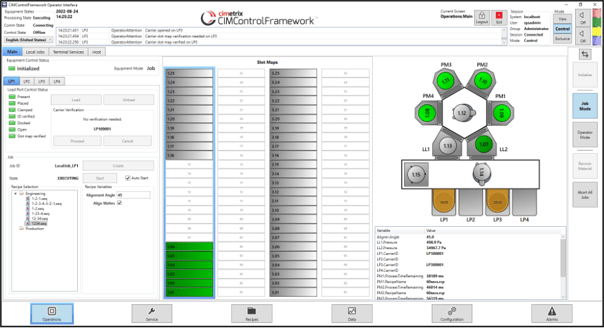

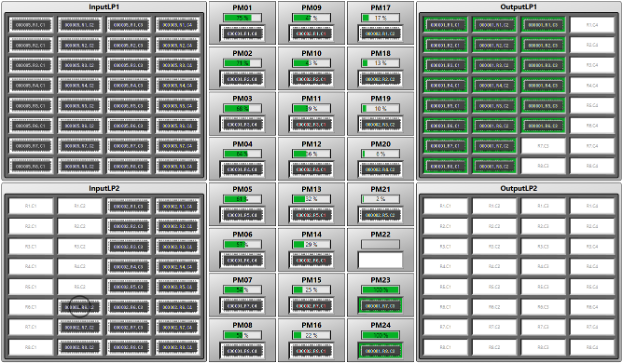

Both visualization examples were created with the same visualization library.

Both visualization examples were created with the same visualization library. These interlocks are generally based on states and are equipment-dependent. Software interlocks are not a replacement for hardware interlocks. Software interlocks are like a safety net—they are not normally needed, but when they are, there is a much lower risk of damage.

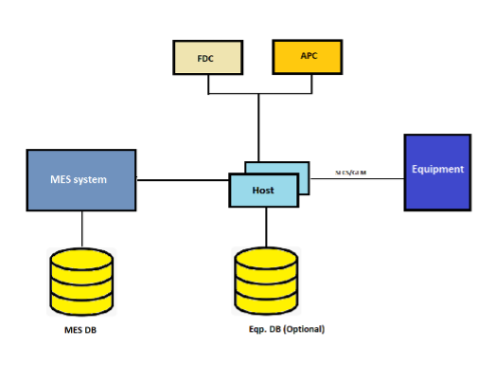

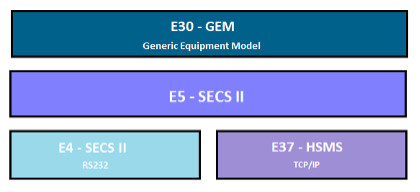

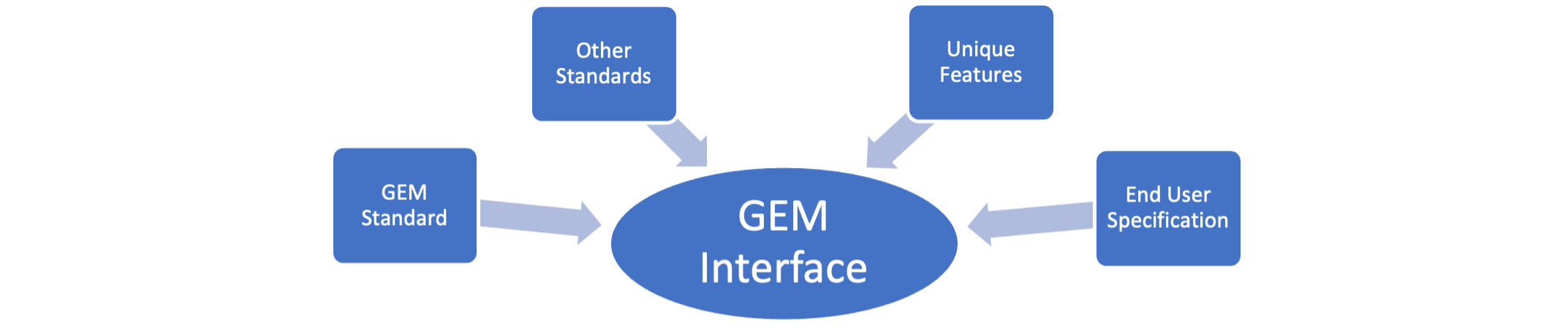

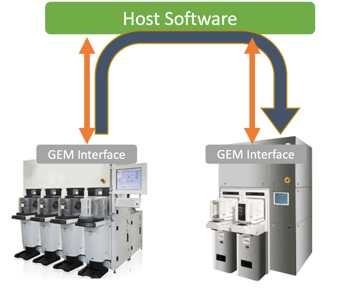

These interlocks are generally based on states and are equipment-dependent. Software interlocks are not a replacement for hardware interlocks. Software interlocks are like a safety net—they are not normally needed, but when they are, there is a much lower risk of damage. While it was cool to be able to connect to process or metrology equipment and collect data, specify the process, and monitor alarms, it was a big task to develop factory systems that interface to the equipment because each SECS-II interface was unique. One of the first tasks required when developing an interface was to perform an equipment characterization to understand and document the details of the SECS messages used by each equipment. The characterization report became the guide for developing the factory side interface to that particular piece of equipment.

While it was cool to be able to connect to process or metrology equipment and collect data, specify the process, and monitor alarms, it was a big task to develop factory systems that interface to the equipment because each SECS-II interface was unique. One of the first tasks required when developing an interface was to perform an equipment characterization to understand and document the details of the SECS messages used by each equipment. The characterization report became the guide for developing the factory side interface to that particular piece of equipment.