Previous blog posts have discussed the merits of choosing a commercial software platform for implementing the equipment side of EDA (Equipment Data Acquisition) and how you would use that package to differentiate your equipment data collection capabilities from your competitors.

In this post, we discuss how to design the equipment model to contain enough information to make it useful without publishing so much data that it becomes cumbersome for your factory customers to find the data that is most important to them.

Data to Publish

The automation requirements for the most advanced fabs call for the latest versions (Freeze II) of all the standards in the EDA suite, including the EDA Common Metadata (SEMI E164) standard. In addition to providing an excellent foundation for a new equipment model, E164 enables consistent implementation of GEM300, commonality across equipment types, automation of many data collection processes, less work to interpret collected data, and true plug-and-play client applications—all of which contribute to major increases in engineering efficiency. These capabilities benefit both the equipment suppliers and their factory customers alike. Therefore, equipment models should make all E164-compliant data available.

To summarize, those who remember the complexity of implementing SECS-II before GEM came along (pre-1992) will understand this analogy: E164 is to EDA what GEM was to SECS-II.

- Fab-specified Data

The second blog post made the following statement:

“This is why the most advanced fabs have been far more explicit in their automation purchase specifications with respect to equipment model content, going so far as to specify the level of detailed information they want to collect about process performance, equipment behavior, internal control parameters, setpoints and real-time response of common mechanisms.”

You only have to read the latest requirements specs for these fabs to get more specifics. Pick the one from your customer base that sets the bar highest and let that be your target.

Data to Avoid in the Model

It is easy to fall into the mindset that if publishing some data through the EDA interface is desirable, the more data we can publish, the better. This is not always the case. In his fascinating book, The Paradox of Choice, Barry Schwartz makes the case that freedom is defined by one’s ability to choose, but more choice doesn’t mean more freedom. In fact, too many choices actually cripple one’s ability to choose. The same can be said of data published in an EDA interface. Making too much data available actually hinders the creation of EDA client applications.

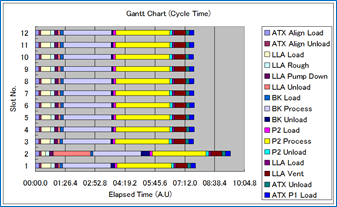

We were recently working with a fab to perform a proof-of-concept where we connected an EDA client to a piece of equipment with an EDA interface. We were able to connect to the equipment in a matter of minutes, but finding suitable data to collect for our proof-of-concept took almost an hour because there was so much superfluous data published from the equipment.

Publishing everything including the kitchen sink reduces the ability to create an efficient EDA client application.

Some examples of data to avoid publishing in the model include:

- Parameters that have no value – If a parameter is available in the model, but the value is not published by the equipment control application, that parameter is just extra noise in the interface. Consider not adding it to the model.

- Parameters with values that do not change – If a parameter value does not change during the life of the application, it does not make sense to collect that parameter’s data. For example, if an application uses an equipment constant, it may not be necessary to publish that constant through the EDA model.

- Irrelevant data – If a parameter contains data that is irrelevant to data publication, it should not be added to the model. For example, having parameters in the model that contain the IP address or port number for connection are not very useful in the equipment model. This information is necessary in connecting with an EDA client, but is not relevant for data collection in the model.

The takeaway: Publish data required by E164 and additional fab-specified data, but carefully evaluate other data to be published to make sure it is relevant and useful for data collection.

If you have questions about Equipment Data Acquisition or would like a demo of the functionality described above, please contact Cimetrix to schedule a discussion.

You can download an introduction to EDA White Paper any time.

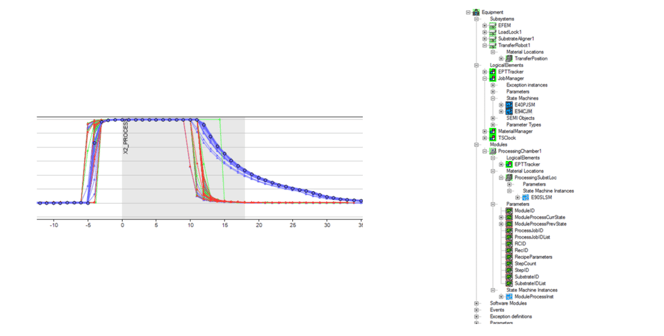

The automation requirements for the most advanced fabs call for the latest versions (Freeze II) of all the standards in the EDA suite, including the EDA Common Metadata (E164) standard. Dealing with older versions of the standard in the factory systems creates unnecessary work and complexity for the fab’s automation staff, so it is best to implement the latest versions from the outset. The Cimetrix CIMPortal Plus product makes this a straightforward process using the model development and configuration tools in its SDK (Software Development Kit), so there is absolutely no cost penalty for providing the latest generation of standards in your interface.

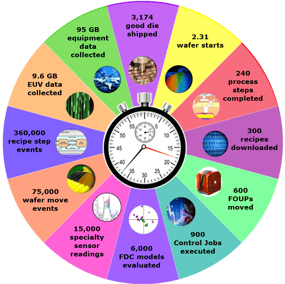

The automation requirements for the most advanced fabs call for the latest versions (Freeze II) of all the standards in the EDA suite, including the EDA Common Metadata (E164) standard. Dealing with older versions of the standard in the factory systems creates unnecessary work and complexity for the fab’s automation staff, so it is best to implement the latest versions from the outset. The Cimetrix CIMPortal Plus product makes this a straightforward process using the model development and configuration tools in its SDK (Software Development Kit), so there is absolutely no cost penalty for providing the latest generation of standards in your interface.  This is why the most advanced fabs have been far more explicit in their automation purchase specifications with respect to equipment model content, going so far as to specify the level of detailed information they want to collect about process performance, equipment behavior, internal control parameters, setpoints and real-time response of common mechanisms like material handling, vacuum system performance, power generation, consumables usage, and the like. This level of visibility into equipment operation is becoming increasingly important to achieve the required yield and productivity KPIs (Key Performance Indicators) for fab at all technology nodes.

This is why the most advanced fabs have been far more explicit in their automation purchase specifications with respect to equipment model content, going so far as to specify the level of detailed information they want to collect about process performance, equipment behavior, internal control parameters, setpoints and real-time response of common mechanisms like material handling, vacuum system performance, power generation, consumables usage, and the like. This level of visibility into equipment operation is becoming increasingly important to achieve the required yield and productivity KPIs (Key Performance Indicators) for fab at all technology nodes.  Before the fab’s automation team can fully integrate a new piece of equipment, it must follow a rigorous acceptance process that includes a comprehensive set of interface tests for standards compliance, performance, and reliability. This process is vital because solid data collection capability is fundamental for rapid process qualification and yield ramp that shorten a new factory’s “time to money.” If you know what acceptance tests and related software tools the fab will use (which is now explicit in the latest EDA purchase specifications), you can purchase the same software tools, perform and document the results of these same tests before shipping the equipment.

Before the fab’s automation team can fully integrate a new piece of equipment, it must follow a rigorous acceptance process that includes a comprehensive set of interface tests for standards compliance, performance, and reliability. This process is vital because solid data collection capability is fundamental for rapid process qualification and yield ramp that shorten a new factory’s “time to money.” If you know what acceptance tests and related software tools the fab will use (which is now explicit in the latest EDA purchase specifications), you can purchase the same software tools, perform and document the results of these same tests before shipping the equipment.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

The question now becomes “How DO the industry’s leading manufacturers ensure the equipment they buy will support their Smart Manufacturing objectives?” This presentation explains how the careabouts of key stakeholder groups are “translated” into specific equipment automation and communications interface requirements which can then be directly included in the equipment purchasing specifications. As more semiconductor manufacturing companies take this approach, effectively “raising the bar” for the entire industry, the collective capability of the equipment suppliers will increase in response, to everyone’s benefit.

The question now becomes “How DO the industry’s leading manufacturers ensure the equipment they buy will support their Smart Manufacturing objectives?” This presentation explains how the careabouts of key stakeholder groups are “translated” into specific equipment automation and communications interface requirements which can then be directly included in the equipment purchasing specifications. As more semiconductor manufacturing companies take this approach, effectively “raising the bar” for the entire industry, the collective capability of the equipment suppliers will increase in response, to everyone’s benefit.