SEMI E164

Specification for EDA Common Metadata

The purpose of the E164 specification is to encourage companies developing EDA/Interface A connections to implement a more common representation of equipment metadata. By following the E164 standard, equipment suppliers and fabs can establish greater consistency from tool-to-tool and from fab-to-fab. That consistency will make it easier and faster for equipment suppliers to provide a consistent EDA interface, and for fabs to develop EDA client applications.

The primary benefit of common metadata is that equipment suppliers will no longer have to worry about the specific requirements of one semiconductor fab versus another. Metadata also empowers engineers at the fab by allowing the automation of data collection plans. Typical events and context data should already be known, and the fab engineers need only add the process data. In addition, fab engineers can select the events and data they need from an approved pick list, eliminating the need to get other departments, such as IT, involved every time a change is required.

Background

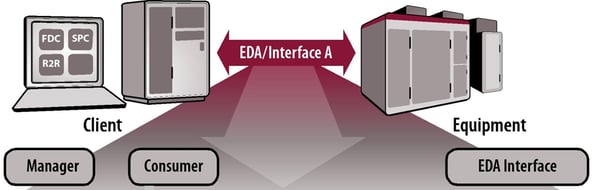

Equipment Data Acquisition (EDA) - also referred to as Interface A - offers semiconductor manufacturers the ability to collect a significant amount of data that is crucial to the manufacturing process, including descriptions of the equipment's structure and behavior. This data is represented on the equipment as a model, which is communicated to EDA clients as metadata sets. The metadata, based upon the SEMI E125 Specification for Equipment Self-Description, includes the equipment components, events, and exceptions, along with all the available data parameters.

Since the advent of the SEMI EDA standards, developers and fabs have recognized that equipment models, and the resulting metadata sets, can vary greatly. It is possible to create a model for one piece of equipment that is compliant with the EDA standards, but is quite different from the model for another piece of equipment, which is also standard-compliant. This makes it difficult for the fabs to know reliably where to find the data they are interested in from one type of equipment to another.

SEMATECH (ISMI) launched an initiative in to make the transition to EDA easier and ensure consistency of equipment models and metadata from tool-to-tool. SEMATECH provided leadership and guidance on the EDA standards, EDA Common Metadata, the Metadata Conformance Analyzer (MCA), and the Equipment Data Acquisition (EDA) Version 0710 Guidance document. This document provides technical guidance to facilitate consistent and complete metadata definitions according to SEMI E125. In addition, Cimetrix and SEMATECH collaborated to develop the original Equipment Client Connection Emulator, also known as ECCE, (now further developed by Cimetrix into ECCE Plus to support both Freeze Version I and Freeze Version II). SEMATECH drove the effort to improve the quality metadata, and the result was the E164 standard, approved in July 2012.

E164, which extends the SEMI E125-0710 Equipment Self-Description standard, defines the common metadata set that will support consistent implementation of EDA/Interface A Freeze Version II. The E164 standard also supports SEMI GEM 300 standards E30, E40, E87, E90, E94, E148, and E157 standards. Through our leadership role in the DDA Task Force, Cimetrix has played a major part in defining E164. With this specification, equipment modeling will be more clearly defined and provide more consistent models between OEMs, which will make it easier for EDA/Interface A users to navigate models and find the data they need.

Now equipment suppliers have a standard they can use to generate the equipment models, and fabs have a standard they can use to generate their client-side applications. GLOBALFOUNDRIES has been actively working to adopt the new E164 standard as part of their EDA acceptance criteria. This requirement will help accelerate the adoption of EDA/Interface A as well as the new E164 standard by OEMs and ultimately by other fabs.

Conforming to Common Metadata Standards

SEMI E164 standard provides predictable names/IDs and data parameters for key content standards, along with rules for self-consistency within the metadata. It also includes new components for organization, such as the universal use of "EFEM" for the Equipment Front End Module that encapsulates load ports, carrier locations, carrier handlers, and other associated mechanisms.In order to ensure consistency of metadata from machine-to-machine, some semiconductor manufacturers, such as GLOBALFOUNDARIES, will require compliance with E164 as validated with the SEMATECH Metadata Conformance Analyzer (MCA). MCA is the industry standard means for automated checking for conformance of equipment metadata to applicable portions of the SEMI standards and SEMATECH guidelines, and exposes errors and inconsistencies in the generated metadata. By using MCA, both OEMs and semiconductor manufacturers will be able to attain consistency in the representation of 300mm data, objects, and events within the EDA/Interface A standards. Those supported standards include E30, E40, E87, E90, E94, E116, E157, and the new E164 standard. See the section below discussing how those GEM standards are comprehended by the E164 standard.

One important factor equipment developers will need to recognize is that it is possible to create a Freeze Version II compliant interface that will not pass MCA testing. Knowing this makes understanding the requirements for compliance with both Freeze Version II and E164 will be vital before beginning the design.

Standardizes Representation of Content Standards

Prior to the publication of the SEMI E164 standard, OEMs could decide whether or not to include GEM parameters in their equipment models. If they decided to include them, they used their own format, including element names/IDs, and data parameters. The result was that fabs could install equipment that had no consistency in equipment models from one machine to another.

Now with E164, OEMs are required to include GEM parameters in their equipment models, and they must use the guidelines specified by E164. The result should be consistency of equipment models from one machine to another, not only for the EDA/Interface A data, but also for the GEM/GEM 300 content standards such as E30.

The table below shows the SEMI standards addressed in E164.

SEMI Standards Also Addressed by E164

| SEMI Standard | 1105 Freeze | 0710 Freeze | |

| Versions Provided | Available Via User Modification | Versions Provided | |

| E30 GEM | E30-1103 E30-0307 |

E30-0303 | E30-0307 |

| E40 Processing Management |

E40-0304

E40-0705 E40-0709 |

E40-1102 E40-0307 E40-0703 E40-1107 E40-1106 |

E40-0709 |

| E87 Carrier Management | E87-1105 E87-0709 |

E87-0303 E87-0705 E87-0703 E87-0706 E87-0304 E87-0707 |

E87-0709 |

| E90 Substrate Tracking | E90-0304 E90-1105 E90-0707 |

E90-0303 E90-0705 E90-0703 E90-0306 E90-1104 E90-0706 |

E90-0707 |

| E94 Control Job Management | E94-0705 E94-0309 |

E94-0702 E94-1107 E94-1104 E94-0308 E94-0306 E94-1108 E94-1106 |

E94-0309 |

| E116 Equipment Performance Tracking | E116-0705 E116-0707 |

E116-0303 E116-1104 E116-0703 E116-0306 E116-0304 E116-0706 E116-0704 |

E116-0707 |

| E148 Time Synchronization | N/A | N/A | E148-1109 |

| E157 Module Process Tracking | E157-0710 | N/A | E157-0710 |

To download the E164 specification, visit the Download E164 webpage on the SEMI website.

(Note: there is a charge to download the specification.)