The COVID-19 pandemic is impacting businesses worldwide, and in many regions, working from home is now mandatory or at least strongly encouraged.

The COVID-19 pandemic is impacting businesses worldwide, and in many regions, working from home is now mandatory or at least strongly encouraged.

While this doesn’t pose a major disruption for many types of jobs, it can be problematic for people working with the automation features of advanced manufacturing equipment. The network connections to production equipment are normally part of a secure factory system infrastructure, which makes them almost impossible to reach from outside the company’s intranet. Luckily, for those responsible for testing and characterizing the SEMI EDA (Equipment Data Acquisition, also known as Interface A) interfaces on new 300mm equipment, this should only be a minor inconvenience. And why is that?

The choice of internet technologies (Web Services, SOAP/XML) as the foundation for the EDA standards makes it easy to connect to a piece of equipment over the internet as long as the user’s client computer can “reach” the connection URLs of the equipment (and vice versa). What this probably means in practice is setting up a VPN (Virtual Private Network) connection from your client computer (say, the laptop you normally use) to the company’s network. This is something that road warriors and remote employees must often do as a matter of course to access internal file systems, in-house applications, and other private information.

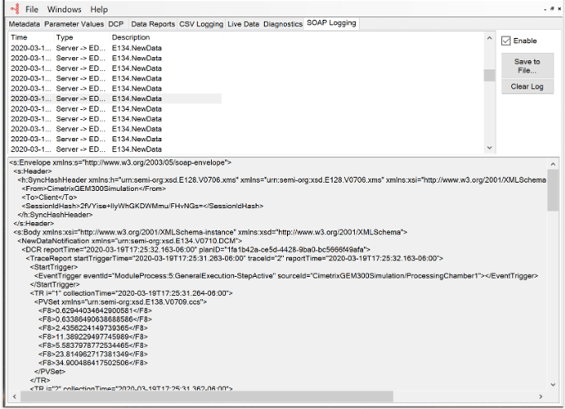

Once this is done, you can connect to the various service URLs for that equipment by including the remote computer name in the session connection strings. Note that you may have to modify the firewall settings of your client machine so the E134 NewData messages can find their way back to you. This is necessary because these are NOT request/reply messages like many of the EDA services; rather, they are initiated from the equipment, so your application has to be listening for them on the Consumer URL. This address is passed to the equipment when the connection session is first defined and established.

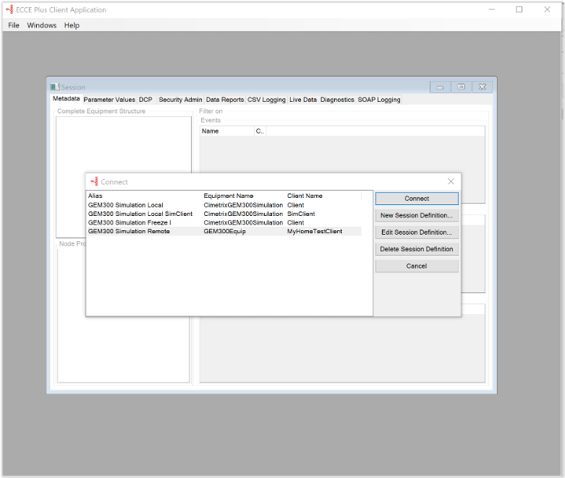

Using the Cimetrix ECCE Plus client product as an example, here is how I would set up a remote (from home!) session with an EDA-enabled 300mm equipment simulator running in our office on a machine named “edasimulator.” The first screenshot shows the choice of connections defined for my instance of the ECCE Plus; note that last one in the list that is highlighted.

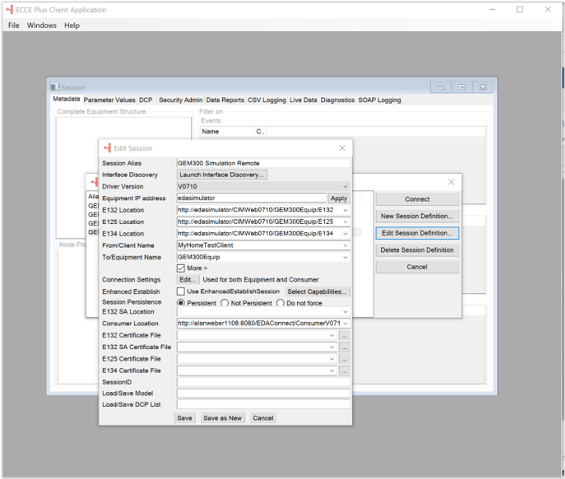

Clicking on the “Edit Session Definition” button and then the “More >” checkbox yields the screen below. You can see that the equipment IP address is “edasimulator” (the remote computer name referenced above) and each of the Freeze II service URLs (E132 Location, E125 Location, and E134 Location) for the session are defined on that machine.

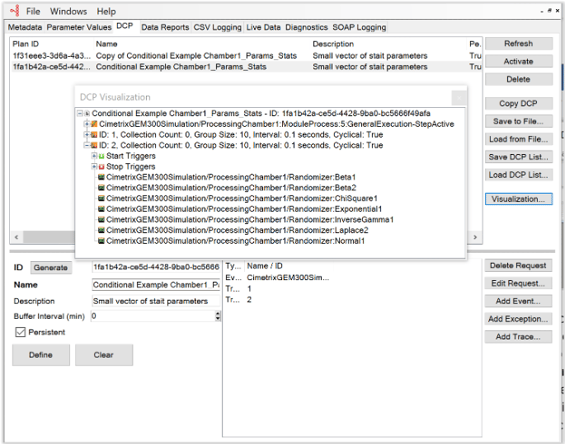

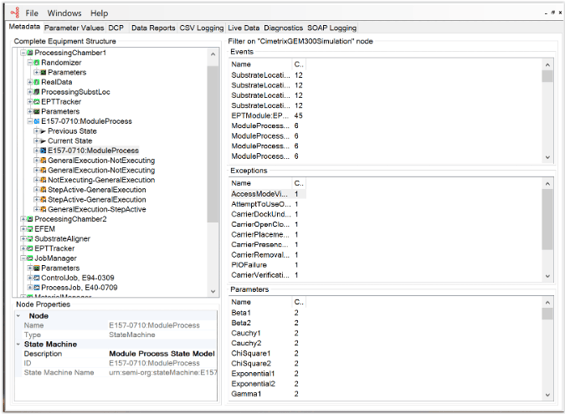

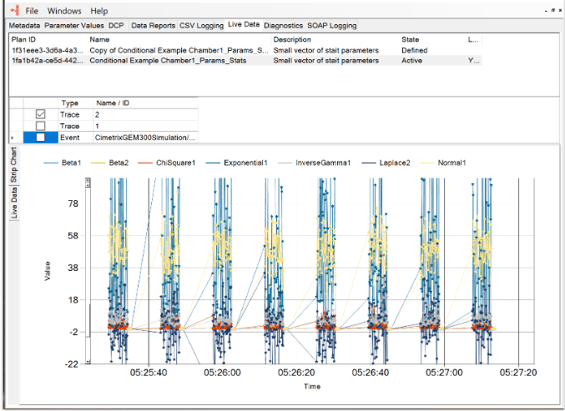

Note that the client ID (From/Client Name), which is “MyHomeTestClient,” must also be defined in the equipment’s Access Control List (ACL). For me to be effective, this client must have sufficient privileges for the kinds of work I need to do, which may include using existing DCPs (Data Collection Plans), creating additional DCPs, viewing interface configuration parameters (e.g., Max Sessions) and ACL entries, browsing the metadata model, and looking at the SOAP logs. Results of some of these tasks using the ECCE Plus are shown below.

This may sound like a lot of trouble, but with a little help from your company’s IT support team, you can follow the “shelter in place” guidelines and STILL work effectively on your EDA-related tasks. And when the current crisis has passed, you’ll know how to be even more effective when you’re on the road!

We hope the posting is useful for you, and most importantly, that you and your loved ones stay safe and calm.