The SEMI North American standards meetings for the Information and Control Committee were held recently and the following is a summary of some of the highlights and action items.

In the GEM 300 task force, a revision to GEM officially removed E139 as a recipe management option. A planned revision to GEM should be much more exciting and progressive, but this work cannot begin until E30 is published with the current changes. In the meantime, future near-term plans include defining new SECS-II messages to improve host access to data collection setup and some terminology clarification. Brian Rubow from Cimetrix continues to co-lead this task force with Chris Maloney of Intel.

In the DDA (Diagnostics Data Acquisition) task force, which Brian Rubow from Cimetrix continues to co-lead, the standard that establishes gRPC and Protocol Buffers for EDA freeze 3 was approved. However proposed changes to the other core standards E125, E132 and E134 all failed, as well as the gRPC adoption for E132. The failures were expected. Additionally the North America DDA task force leaders continue to actively collaborate with the co-leaders of the DDA task force in South Korea. It is a great example of competitors working together at SEMI to create common solutions that satisfy everyone’s requirements.

Tami Tracy, a Cimetrix Solutions Engineering Manager, was officially voted in as a GUI task force co-leader for 2020, co-leading with Frank Summers. Congratulations and thanks to Tami for volunteering for this position. This will accelerate the task force's plans to modernize the SEMI E95 standard.

The Computer and Device Security (CDS) task force announced a vastly improved collaboration with its sister organization in Taiwan which has officially agreed to "divide and conquer" rather than attempting to address the entire scope of this domain with a single standard. A few months ago, the two groups seemed to be at odds with each other...The Taiwan task force proposed to include all factory and equipment security issues in one effort, while the North American task force wanted to focus initially on the equipment issues. The Taiwan, Japan and North America Task Force Leadership have now agreed to convert the Specification for Malware Free Equipment Integration (SNARF) 6506 into an overarching standard. The CDS task force is moving forward on SNARF 6566, and received authorization for a ballot on this proposed new standard for Cycle 2-2020.

The Advanced Factory Factory Integration (ABFI) task force, headed by Brian Rubow (Director of Solutions Engineering, Cimetrix) and Dave Huntley (PDF Solutions), held its first task force meeting. One order of business is to update E142 substrate mapping. The task force intends to map equipment features to SEMI standards including GEM and GEM 300. This effort could facilitate adoption of the GEM standard on equipment that previously had little interface standardization. It should also encourage further advance the goals of Smart Manufacturing and Industry 4.0 in related industries, encouraging more factories and equipment to adopt the standards that have been so successfully applied in semiconductor manufacturing for decades.

To find out more, you can speak with an industry standards expert today by clicking the link below.

The 31st annual APC Conference is now in the history books, and the diversity of topics, presenters, and local distractions made it well worth the visit to San Antonio! This year’s agenda featured half-day tutorials on the basics of APC and cyber-security, keynotes from chip makers and leading suppliers on automotive industry requirements, smart equipment, and smart manufacturing, and a series of packed technical sessions covering sensors and equipment control, fault detection and feedforward/feedback control, advanced analytics, and standards.

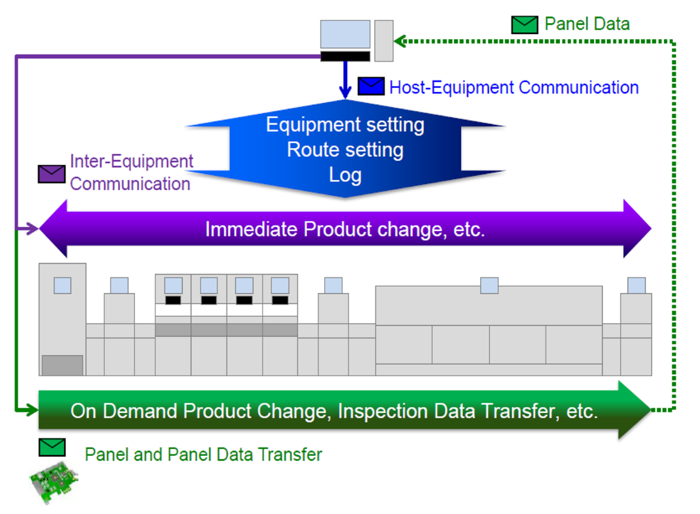

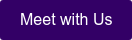

The 31st annual APC Conference is now in the history books, and the diversity of topics, presenters, and local distractions made it well worth the visit to San Antonio! This year’s agenda featured half-day tutorials on the basics of APC and cyber-security, keynotes from chip makers and leading suppliers on automotive industry requirements, smart equipment, and smart manufacturing, and a series of packed technical sessions covering sensors and equipment control, fault detection and feedforward/feedback control, advanced analytics, and standards. The SMT-ELS standard has come a long way in a short time, and the ambitious, integrated demonstration created by 4 major SMT suppliers (Fuji, Juki, Panasonic, Yamaha) that was exhibited in June (Japan) and August (China) will again be shown in productronica (Munich, 13-15 November). The basic functions of SMT-ELS (officially designated at SEMI A1, A1.1, and A2) appear in the figure below.

The SMT-ELS standard has come a long way in a short time, and the ambitious, integrated demonstration created by 4 major SMT suppliers (Fuji, Juki, Panasonic, Yamaha) that was exhibited in June (Japan) and August (China) will again be shown in productronica (Munich, 13-15 November). The basic functions of SMT-ELS (officially designated at SEMI A1, A1.1, and A2) appear in the figure below. Cimetrix will likewise demonstrate this new standard at productronica, showing not only an equipment-level implementation of the M2M features but also the host-based configuration process and a plug-in for doing protocol validation tests.

Cimetrix will likewise demonstrate this new standard at productronica, showing not only an equipment-level implementation of the M2M features but also the host-based configuration process and a plug-in for doing protocol validation tests. If you would like any further information, you can speak with a Cimetrix expert, or you can stop by our booth at productronica this week (Hall A3 booth 451).

If you would like any further information, you can speak with a Cimetrix expert, or you can stop by our booth at productronica this week (Hall A3 booth 451).

This conference is one of the longest-running events specific to the semiconductor manufacturing industry, and always features speakers and topics that are germane to the industry’s leading practitioners of equipment/factory data collection, analysis, optimization, and control. This year’s agenda promises more of the same –

This conference is one of the longest-running events specific to the semiconductor manufacturing industry, and always features speakers and topics that are germane to the industry’s leading practitioners of equipment/factory data collection, analysis, optimization, and control. This year’s agenda promises more of the same –  The Cimetrix Resource Center is a great way to familiarize yourself with standards within the industry as well as find out about new and exciting technologies.

The Cimetrix Resource Center is a great way to familiarize yourself with standards within the industry as well as find out about new and exciting technologies.