The SEMI North American Information & Control Committee meetings were held in Milpitas, CA at SEMI headquarters. The following activities might be important for Cimetrix customers and employees.

The DDA Task Force has officially kicked off the development of the next EDA standards, already deemed “Freeze 3” by many. Several ballots have been authorized for creation and voting early next year. This includes ballots to modify E125, E132, E134 and E138, which includes many of the core EDA standards. Additional work is also planned for E164. Most of the changes are expected to be straightforward, with a few corrections, clarifications and new features that various SEMI members have requested. E125 is probably the biggest proposed change in this set, where new messages will be added to provide the list of all parameters and the list of all events. Then the equipment nodes in the model will always reference parameters and reference events. This should clarify some of the confusion surrounding parameter definitions and parameter references.

By far, the longest discussion was surrounding the biggest decision of all. Currently, the EDA standards are using HTTP/1.1 for message transfer and SOAP/XML for message body. This means that the EDA standards are text based. At the time of EDA development, this seemed to be the best internet technology for data collection. Today, HTTP/1.1 is out of date. More recently, advances have been made in internet technology for sharing data in a binary format. The biggest advantage of transferring data in a binary message format is message efficiency. A binary message generally will be about 15 to 20 times smaller than text based messaging. This means less load on the equipment that publishes EDA data, much less load on the network and less load on the subscribing EDA clients. Many alternatives were discussed including WebSockets, HTTP/2, and even HSMS. It was discussed whether to stick with a text based protocol and use compression or move to a binary protocol. Data was presented from a DDA Task Force member regarding a performance comparison between HTTP/1.1 with text messages (like EDA today), HTTP with binary messages, HTTP/2 with SSL, WebSockets with binary messages and WebSockets with SSL. The test results showed binary messaging to be allow 25 times more data collection than the current HTTP/1.1 technology. Ultimately, it was decided that moving to a binary protocol was the right strategic direction.

Another point of discussion was how to implement binary messaging. Google has developed the Protocol Buffer technology. Specifically, we looked at version 3 called “proto3” which defines a notation for establishing binary messages. They have also published open source code gRPC in various software programming languages that implement the binary encoding and decoding for the Protocol Buffer technology and HTTP/2. This seems to be today’s best technology for binary web services. The DDA Task Force is in the process of developing a ballot to propose the adoption of this technology for the EDA messages. If approved, this would be the foundation of freeze 3 communication and a vast improvement.

In Japan, the Information & Control Committee recently created a DDA task force. The leader, Mitch Sakamoto from company ZAMA is coordinating with the North American DDA task force. Similarly, the DDA task force leaders in Korea are also working closely with North America. The Freeze 3 EDA development really is emerging as a worldwide coordinated development. The world-wide cooperation and coordination is much stronger and cohesive than the development was for Freeze 1 and Freeze 2.

The GEM 300 task force passed a ballot approving the use of SECS Message Notation (SMN) for GEM implementations. SMN could already be used anyway, but adding this to the GEM standard makes its use more official. This means that messages can be logged and documented using SMN.

The GUI task force continues to move along with planned improvements for the E95 standard. This including modernizing the graphics in the standard, updating the text and most importantly having the standard include the adoption of small screen devices as an equipment HMI. The new E95 standard will be a major revision standard.

In Korea, several ballots continue to be developed and reworked. This includes an update to the E87 carrier management services standard to allow more precise reporting when carrier approach the completion state. This includes an update to the E142 wafer map handling standard with new features in the schema file. Additionally, they are working on an equipment generic counter standard, which establish standardized methods for equipment to “count” things that happen on the equipment. This proposed specification is a favorite of mine personally. It is a clever way to recognize that it is important to count things on every equipment such as the number of times a vacuum has a been cycled, the number of times a nozzle has been used, the number of times a user has logged in, the number of times a robot has moved a substrate, the number of times an equipment has been restarted. It could be anything and it could be very different on two types of equipment. Collecting such data in a generic, natural way facilitates predictive maintenance; a key to minimizing factory equipment downtime.

Cimetrix participated in the recent European Advanced Process Control and Manufacturing (apc|m) Conference, along with over 150 control professionals across the European and global semiconductor manufacturing industry. The conference was held in Dublin, a lively city on the east coast of Ireland which features a charming juxtaposition of old and new and is home to 1.2 million of the friendliest and most talkative people on the planet!

Cimetrix participated in the recent European Advanced Process Control and Manufacturing (apc|m) Conference, along with over 150 control professionals across the European and global semiconductor manufacturing industry. The conference was held in Dublin, a lively city on the east coast of Ireland which features a charming juxtaposition of old and new and is home to 1.2 million of the friendliest and most talkative people on the planet!

Cimetrix was one of the sponsors of the conference. Dresden is hot bed for semiconductor manufacturing in Europe. In fact, 50% of the chip output from Europe comes from Dresden. The conference is organized by the Automation Network Dresden which consists of 5 Dresden based companies; AIS, HAP, Ortner, SYSTEMA and Xenon. SYSTEMA is a Cimetrix partner and helps us with integration projects.

Cimetrix was one of the sponsors of the conference. Dresden is hot bed for semiconductor manufacturing in Europe. In fact, 50% of the chip output from Europe comes from Dresden. The conference is organized by the Automation Network Dresden which consists of 5 Dresden based companies; AIS, HAP, Ortner, SYSTEMA and Xenon. SYSTEMA is a Cimetrix partner and helps us with integration projects.

SEMI North America Information & Control Task Force and Committee fall meetings were last held at SEMI headquarters November 7 through 9, 2016. During these meetings, SEMI announced that they are relocating their headquarters to Milpitas, CA. That move is currently underway. In the GEM 300 task force, all of the ballots failed to pass. This include ballot 5872A, 5549, 6026, 6066, and 6068. In the DDA task force, ballot 6064 also failed.

SEMI North America Information & Control Task Force and Committee fall meetings were last held at SEMI headquarters November 7 through 9, 2016. During these meetings, SEMI announced that they are relocating their headquarters to Milpitas, CA. That move is currently underway. In the GEM 300 task force, all of the ballots failed to pass. This include ballot 5872A, 5549, 6026, 6066, and 6068. In the DDA task force, ballot 6064 also failed.

We highlighted our CIMPortal Plus software demonstrating the benefits of the SEMI E164 standard. Attendance seemed light this year which allowed the Cimetrix team ample time to meet with various equipment supplier customers who had exhibits at the show. Of particular interest to our customers was our advice on when and how to add Interface A to their control systems, and what impact Industry 4.0 and smart manufacturing will bring. The evening networking event was very well done; congrats to the SEMI team.

We highlighted our CIMPortal Plus software demonstrating the benefits of the SEMI E164 standard. Attendance seemed light this year which allowed the Cimetrix team ample time to meet with various equipment supplier customers who had exhibits at the show. Of particular interest to our customers was our advice on when and how to add Interface A to their control systems, and what impact Industry 4.0 and smart manufacturing will bring. The evening networking event was very well done; congrats to the SEMI team.

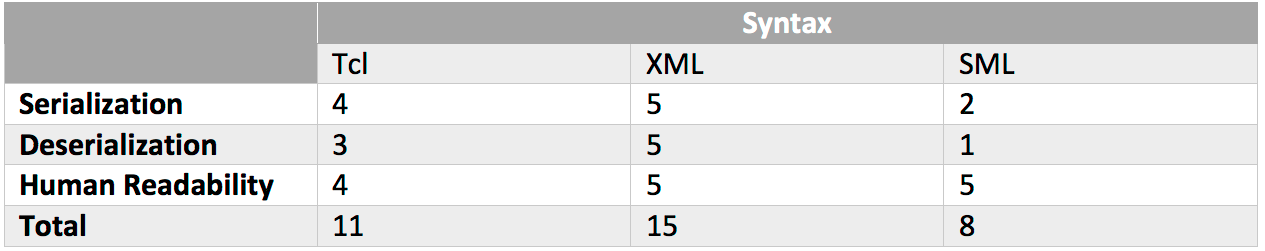

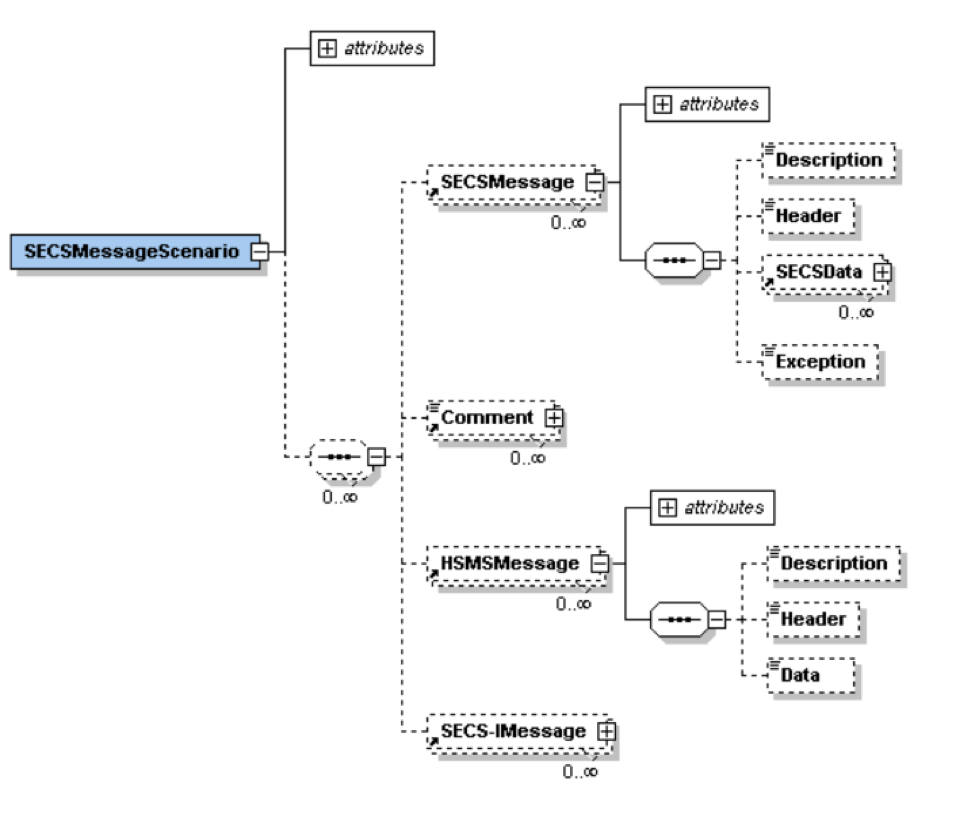

In a previous blog we mentioned that two new SEMI standards, E172 and E173, demonstrated that the GEM standard was alive and well and even gaining new momentum by evolving to adopt new technology. The earlier blog focused on E172 with its SEDD files that use an XML schema to describe what is in a GEM interface. Today’s blog is about the E173 Specification for XML SECS-II Message Notation: a new way to log and document GEM/SECS messages, again using an XML schema.

In a previous blog we mentioned that two new SEMI standards, E172 and E173, demonstrated that the GEM standard was alive and well and even gaining new momentum by evolving to adopt new technology. The earlier blog focused on E172 with its SEDD files that use an XML schema to describe what is in a GEM interface. Today’s blog is about the E173 Specification for XML SECS-II Message Notation: a new way to log and document GEM/SECS messages, again using an XML schema.