It’s amazing enough to think that a single factory can start 100,000 wafers every month on their cyclical journey through 1500 process steps… and have 99%+ of them emerge 4 months later to be delivered to packaging houses and then on to waiting customers. It’s quite another to realize that all of this happens continuously (24 x 7) and automatically.

“How is this possible?” you ask.

Well, a big part of the solution is the body of SEMI standards which have evolved since the early 80s to keep pace with the ever-changing demands of the industry. From an automation standpoint, many of these standards deal with the communications between manufacturing equipment and the factory information and control systems that are essential for managing these complex, hyper-competitive global enterprises.

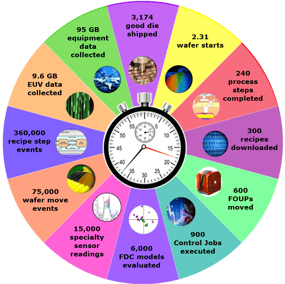

A significant characteristic of these standards is that they have been carefully designed to be “additive.” This means that new generations of SEMI’s communications standards do not supplant or obsolete the previous generations, but rather provide new capabilities in an incremental fashion. To appreciate the importance of this in actual practice, consider how the GEM, GEM300, and EDA/Interface A standards support the transactions that occur in a single Gigafab Minute.

Starting at 1:00 o’clock on the infographic and moving clockwise, you first notice that 2.31 wafers enter the line. Of course, these are actually released in 25-wafer 300mm FOUPs (Front-Opening Unified Pod), but 100K wafers per month translates to 2.31 per minute. Since these factories run continuously, once the line is full, it stays full. And with an average total cycle time of 4 months, this means that there are 400K wafers of WIP (work in process) in the factory at any given time. This number, and the total number of equipment (5000+), drive the rest of the calculations.

GEM (Generic Equipment Model) – SEMI E30, etc.

The GEM messaging standards were initially defined in the early 90s to support the factory scheduling and dispatching applications that decide what lots should go to what equipment, the automated material handling systems that deliver and pick-up material to/from the equipment accordingly, the recipe management systems that ensure each process step is executed properly, and the MES (Manufacturing Execution System) transactions that maintain the fidelity of the factory system’s “digital twin.”

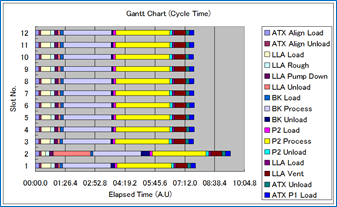

Every minute of every day, GEM messages support and chronicle the following activities: 240 process steps are completed (i.e., 240 25-wafer lots are processed), 300 recipes are downloaded along with a set of run-specific adjustable control parameters, and 600 FOUPs are moved from one place to another (equipment, stockers, under-track storage, etc.). For each of these activities, the factory’s MES is notified instantaneously.

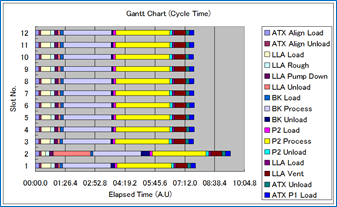

GEM300 – SEMI E40, E87, E90, E94, E157

With the advent of 300mm manufacturing in the mid-to-late 90s, a global team of volunteer system engineers from the leading chip makers defined the GEM300 standards to support fully automated manufacturing operations. Starting at 5:00 o’clock on the infographic, the number of transactions per minute jumps almost 3 orders of magnitude, from the monitoring of 900 control jobs across 4000 process tools to the tracking of 360,000 individual recipe step change events. This level of event granularity is essential for the latest generation of FDC (Fault Detection and Classification) applications, because precise data framing is a key prerequisite for minimizing the false alarm rate while still preventing serious process excursions. In this context, more than 6000 recipe-, product- and chamber-specific fault models may be evaluated every minute.

Simultaneously, the applications that monitor instantaneous throughput to prevent “productivity excursions” and identify systemic “wait time waste” situations depend on detailed intra-tool wafer movement events. In a fab with hundreds of multi-chamber, single-wafer processes, 75,000 or more of these events occur every minute.

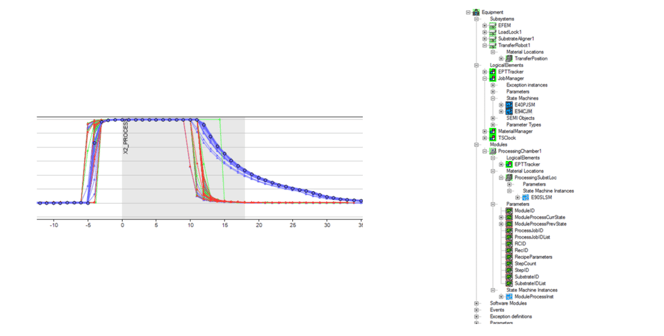

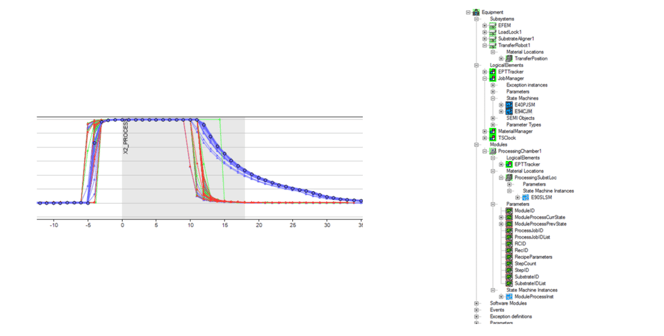

EDA (Equipment Data Acquisition) – SEMI E120, E125, E132, E134, E164, etc.

Rounding out the SEMI standards in our example gigafab is the suite of EDA standards which complement the command and control functions of GEM/GEM300 with flexible, high-performance, model-based data collection. The EDA standards enable the on-demand collection of the volume and variety of “big data” required from the equipment to support the advanced analysis, machine learning, and other AI (Artificial Intelligence) applications that are becoming increasingly prevalent in leading semiconductor manufacturers. As EUV (Extreme Ultraviolet) lithography moves from pilot production to high-volume manufacturing at the 7nm process node and beyond, the litho process area will become a major source of process data by itself, generating 10 GB of data every minute. This is in addition to the 100 GB of data collected from other process areas.

The End Result

The final wedge (12:00 o’clock) in our infographic highlights the real objective – which is producing the millions of integrated circuits that fuel our global economy and provide the technologies that are an integral part of our modern way of life. Assuming a nominal die size of 50 square mm (typical of an 8 GB DRAM), the 2.31 wafers we started at 1:00 o’clock result in almost 3200 individual chips. But none of this would be possible without the pervasive factory automation technology we now take for granted. So, as you finish reading this posting on whatever device you happen to be using, take a micro-moment to acknowledge and thank the hundreds of standards volunteers whose insights and efforts made this a reality!

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

You can see this infographic and much more in the Cimetrix Resource center.

*The Gigafab Minute was inspired by an analogous explication of the scope and impact of today’s Internet from Lori Lewis and Chadd Callahan of Cumulus Media, and published on the Visual Capitalist web site (http://www.visualcapitalist.com/internet-minute-2018/)

![]() 3月20日至22日在上海国际博览中心举行的SEMICON China 2019,不仅是全球规模最大的SEMICON展会,还与Productronica China, Electronica China和FPD China同时举办,集高科技领域于一体,令人惊叹。因此,SEMICON中国吸引了世界领先的技术公司,这些公司设计、开发、制造和供应驱动着当今最复杂的消费和商业产品的微电子产品。这个庞大的群体为这个行业创造了巨大的能量和令人兴奋的事物!这是Cimetrix作为独立参展商参加展会的第一年,整个展会期间我们的展位都很忙碌! 我们的团队成员来自全球各地,包括中国大陆的黄玉峰和刘波(Clare Liu), 来自台湾的Samson Wang, 来自韩国的Hwal Song和来自美国的Bob Reback, Dave Faulkner

3月20日至22日在上海国际博览中心举行的SEMICON China 2019,不仅是全球规模最大的SEMICON展会,还与Productronica China, Electronica China和FPD China同时举办,集高科技领域于一体,令人惊叹。因此,SEMICON中国吸引了世界领先的技术公司,这些公司设计、开发、制造和供应驱动着当今最复杂的消费和商业产品的微电子产品。这个庞大的群体为这个行业创造了巨大的能量和令人兴奋的事物!这是Cimetrix作为独立参展商参加展会的第一年,整个展会期间我们的展位都很忙碌! 我们的团队成员来自全球各地,包括中国大陆的黄玉峰和刘波(Clare Liu), 来自台湾的Samson Wang, 来自韩国的Hwal Song和来自美国的Bob Reback, Dave Faulkner 和Kim Daich。以我们传统的SECE/GEM和EDA产品为特色,我们的展位展示了各种设备的连接和控制解决方案。

和Kim Daich。以我们传统的SECE/GEM和EDA产品为特色,我们的展位展示了各种设备的连接和控制解决方案。![]()

![]()

![]()

シンメトリックスは、来週開催されるセミコンジャパン2018に向け、準備を進めています。今年も皆様にお会いできることを、楽しみにしております。Read now in Japanese or below in English.

シンメトリックスは、来週開催されるセミコンジャパン2018に向け、準備を進めています。今年も皆様にお会いできることを、楽しみにしております。Read now in Japanese or below in English.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

The question now becomes “How DO the industry’s leading manufacturers ensure the equipment they buy will support their Smart Manufacturing objectives?” This presentation explains how the careabouts of key stakeholder groups are “translated” into specific equipment automation and communications interface requirements which can then be directly included in the equipment purchasing specifications. As more semiconductor manufacturing companies take this approach, effectively “raising the bar” for the entire industry, the collective capability of the equipment suppliers will increase in response, to everyone’s benefit.

The question now becomes “How DO the industry’s leading manufacturers ensure the equipment they buy will support their Smart Manufacturing objectives?” This presentation explains how the careabouts of key stakeholder groups are “translated” into specific equipment automation and communications interface requirements which can then be directly included in the equipment purchasing specifications. As more semiconductor manufacturing companies take this approach, effectively “raising the bar” for the entire industry, the collective capability of the equipment suppliers will increase in response, to everyone’s benefit.

Can you think of a better place to spend time with customers and partners than Munich, Germany during Productronica and SEMICON Europa trade fairs? SEMICON Europa has had dwindling attendance in the past few years, even in a hot semiconductor market, so SEMI decided to combine with the robust Productronica for 2017. It was a great decision. This trade fair had 8 full and busy halls as a result; with high spirits from all attendees. Four of the Productronica halls were dedicated to the SMT industry (Surface Mount Technology) which is part of what we call Electronics Assembly. This industry is wrestling with moving to Smart Manufacturing and Industry 4.0. What better way to learn than to have SEMICON Europa next door? SEMICON Europa occupied 1.5 halls filled with many of our current customers.

Can you think of a better place to spend time with customers and partners than Munich, Germany during Productronica and SEMICON Europa trade fairs? SEMICON Europa has had dwindling attendance in the past few years, even in a hot semiconductor market, so SEMI decided to combine with the robust Productronica for 2017. It was a great decision. This trade fair had 8 full and busy halls as a result; with high spirits from all attendees. Four of the Productronica halls were dedicated to the SMT industry (Surface Mount Technology) which is part of what we call Electronics Assembly. This industry is wrestling with moving to Smart Manufacturing and Industry 4.0. What better way to learn than to have SEMICON Europa next door? SEMICON Europa occupied 1.5 halls filled with many of our current customers.