For the first time since the Fall of 2019, the SEMI North America Information & Control Committee (I&CC) was finally able to meet and conduct business online. Throughout all of 2020, the I&CC was not able to meet because SEMI regulations did not at that time allow voting in online meetings. Instead, only the task forces have been meeting. As a result, any passing ballots, unless super clean, had to wait for adjudication in the North America I&CC.

For the first time since the Fall of 2019, the SEMI North America Information & Control Committee (I&CC) was finally able to meet and conduct business online. Throughout all of 2020, the I&CC was not able to meet because SEMI regulations did not at that time allow voting in online meetings. Instead, only the task forces have been meeting. As a result, any passing ballots, unless super clean, had to wait for adjudication in the North America I&CC.

This year, prior to the I&CC meeting on April 1 and 2, all of the associated task forces also met as usual, including the GEM 300, Diagnostic Data Acquisition (DDA), and Advanced Backend Factory Integration (ABFI) task forces. Moreover, the I&CC was able to conduct all the unresolved business that had accumulated over the last year. During the committee meeting, the I&CC successfully used the SEMI Virtual Meeting (SVM) software which runs in an internet browser, allows each committee member to log in, and allows for official voting to take place during the meeting. The North America I&CC will meet again during the summer.

GEM 300 Task Force

In the GEM 300 task force, the primary activity was to officially redefine its charter and scope to match what it has already been doing for the last 20 years. Each SEMI task force defines a “Task Force Organization Force” document (aka TFOF) to establish its charter and scope. Somehow, the GEM 300 task force charter and scope were severely out of date.

In addition to this update, some changes to the E5 standard finally passed voting, pending some final approval. The E5 changes include several new messages and establish definitions for commonly used data collection terminology. The new messages complement the existing set of messages by allowing the host to query information about the current data collection setup. Currently, it is common for a host program to reset and redefine all data collection after first connecting to an equipment because there has been no way to query this information. With these new messages, the host will be able to query the setup and confirm that no data collection has changed while disconnected. Finally, it will be easier to test GEM interfaces with these new messages.

The task force already approved tasks to consider some major work to the GEM standard. The task force is also considering changes to the E116 standard, but there is some resistance to these changes. Here is a summary table of the GEM-related standards activity from across the globe.

|

Region

|

Ballot

|

Standard(s)

|

Status

|

Topic

|

|

South Korea

|

5832

|

New

|

Cycle 5, 2020

|

Generic Counter

|

|

South Korea

|

6695

|

E87

|

Adjudication

|

Ready to unload prediction changes.

|

|

North America

|

6572

|

E30

|

Development

|

Add Stream 21, more stream 2, Cleanup Process Program Management.

|

|

North America

|

6552

|

E5

|

Adjudicated Spring 2021

|

Data collection setup, terminology. Ratification ballot proposed.

2 line-items pending since Summer 2020

|

|

North America

|

6598

|

E37, E37.1

|

Cycle 7, 2020

|

Standardize TCP/IP port numbers

|

|

North America

|

6597

|

E173

|

Adjudicated Spring 2021

|

Minor updates, clarification

Pending since Spring 2020.

|

|

North America

|

6647

|

E116

|

SNARF Revision

|

Recommendations from the ABFI task force

|

|

North America

|

6683

|

E148

|

Development

|

Line item revision

|

DDA Task Force

In the Diagnostic Data Acquisition (DDA) task force (responsible for the EDA standards, aka Interface A), freeze 3 development is moving forward. All of the ballots still failed as expected. The number of remaining technical issues nevertheless has dwindled to just a handful. E132, E125, and especially E164 need the most work.

Following is a summary of the previously completed work.

|

Standard (Ballot)

|

Ballot Status

|

Lead

|

|

E132 (6337)

|

Published - 04/29/2019

|

Brian Rubow (Cimetrix)

|

|

E138 (6336)

|

Published - 03/15/2019

|

Brian Rubow (Cimetrix)

|

|

E134 (6335)

|

Published – 03/29/2019

|

Inhyeok Paek (Link Genesis)

|

|

E120 (6434)

|

Published – 05/30/2019

|

Inna Skvortsova (SEMI)

|

|

E145 (6436)

|

Published – 05/31/2019

|

Inna Skvortsova (SEMI)

|

|

E178 (6300)

|

Published – 01/10/2020

|

Mitch Sakamoto (ZAMA)

|

|

E179 (6344A)

|

Published – 03/27/2020

|

Albert Fuchigami (PEER)

|

And here is a summary of the work in progress.

|

Standard (Ballot)

|

Ballot Status

|

Lead

|

|

E125 (6718)

|

Development

|

Brian Rubow (Cimetrix)

Hyungsu Kim (Doople)

|

|

E132 (6719)

|

Development

|

Mitch Sakamoto (ZAMA)

Albert Fuchigami (PEER)

|

|

E134 (6720)

|

Development

|

Brian Rubow (Cimetrix)

|

|

E164

|

|

Alan Weber (Cimetrix)

|

|

E125.2 (6345)

|

Development

|

Albert Fuchigami (PEER)

|

|

E132.2 (6346E)

|

Development

|

Albert Fuchigami (PEER)

|

|

E134.2 (6347)

|

Development

|

Albert Fuchigami (PEER)

|

|

E125 (6527C)

|

To Abolish

|

Replaced by 6718

|

|

E132 (6571C)

|

To Abolish

|

Replaced by 6719

|

|

E134 (6553C)

|

To Abolish

|

Replaced by 6720

|

All of the failed ballots will be reworked and resubmitted for voting. For many of these ballots, it will be the sixth time to go through the SEMI ballot procedure. Consensus is very nearly achieved, and the defects in the ballots have been identified and corrected. Additionally, there are plans to modify SEMI E179, the standard that defines how gRPC will be utilized. While testing EDA freeze 3, Cimetrix has identified two simple ways to modify the E179 protocol buffer files in order to reduce overhead. These and a few other changes will be proposed in a new ballot.

One of the last changes to the freeze 3 standards will be the introduction of passwords. In the current freeze 1 and freeze 2 versions, there are no passwords. Any client that knows a valid, unused Access Control List entry (ACL, the equivalent of a user name) can connect; therefore, there really isn’t any authentication unless using the SSL protocol with certificates. Passwords will enhance EDA security and facilitate EDA interface setup by allowing client applications to use the same ACL entry while defining a unique password to block other clients from using the same entry. The final E132 ballot will finalize the password feature.

The task force leaders are asking the voting members to raise any final issues before these ballots are submitted to SEMI to the next voting cycle so that we can approve these standards, give implementers a chance to experiment with EDA freeze 3, raise any serious issues that impede the implementation, and then propose the final changes which incorporate that feedback. Until a version of these standards is formally approved, it will be difficult to get concrete and widespread feedback on the new technology, which is a necessary precursor to its adoption and use.

ABFI Task Force

The Advanced Factory Integration task force passed more changes in E142 without controversy. The task force plans to create E142.4, another GEM implementation of E142, designed for larger wafer maps to allow for increased traceability possibilities. Additionally, the task force continues to make plans to develop an adoption matrix as a new standard to describe when GEM and GEM 300 standards should be adopted in backend equipment based on equipment features.

For the first time since the Fall of 2019, the SEMI North America Information & Control Committee (I&CC) was finally able to meet and conduct business online. Throughout all of 2020, the I&CC was not able to meet because SEMI regulations did not at that time allow voting in online meetings. Instead, only the task forces have been meeting. As a result, any passing ballots, unless super clean, had to wait for adjudication in the North America I&CC.

For the first time since the Fall of 2019, the SEMI North America Information & Control Committee (I&CC) was finally able to meet and conduct business online. Throughout all of 2020, the I&CC was not able to meet because SEMI regulations did not at that time allow voting in online meetings. Instead, only the task forces have been meeting. As a result, any passing ballots, unless super clean, had to wait for adjudication in the North America I&CC.

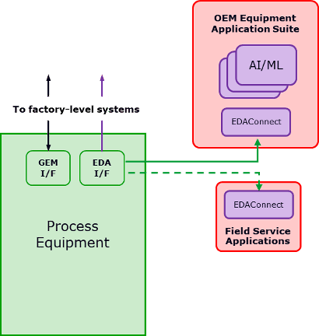

The EDA standards also include a provision for “built-in DCPs” (DCP = Data Collection Plan) which can be shipped with the equipment and protected from accidental deletion at the factory site. These DCPs could be crafted by the equipment supplier to directly feed whatever value-added applications the supplier chose to develop, whether these resided on a computer local to the equipment in the fab, on portable computers used by field service engineers to diagnose problems, or on remote cloud-based systems allowed to connect via secure EDA-defined URLs. This flexibility opens up a wide range of application types, from those that embed equipment-specific algorithms to generic Machine Learning frameworks… the possibilities are endless.

The EDA standards also include a provision for “built-in DCPs” (DCP = Data Collection Plan) which can be shipped with the equipment and protected from accidental deletion at the factory site. These DCPs could be crafted by the equipment supplier to directly feed whatever value-added applications the supplier chose to develop, whether these resided on a computer local to the equipment in the fab, on portable computers used by field service engineers to diagnose problems, or on remote cloud-based systems allowed to connect via secure EDA-defined URLs. This flexibility opens up a wide range of application types, from those that embed equipment-specific algorithms to generic Machine Learning frameworks… the possibilities are endless.