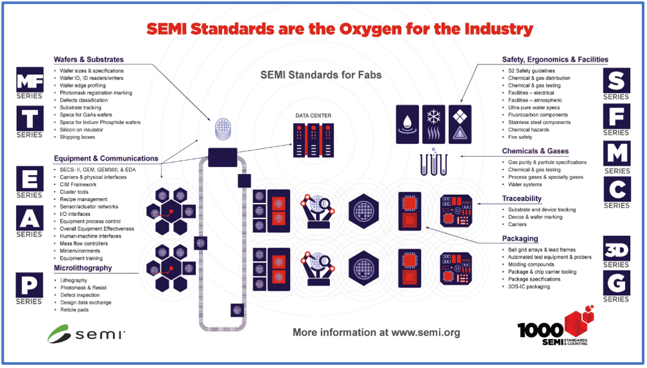

Background

The SEMI North America, the Information & Control Committee meets three times per year, but this year the schedule is changed due to the SEMICON West semiannual relocation to Phoenix beginning this year. SEMI held winter meetings in North America on February 24-26 at SEMI headquarters in Milpitas, CA. Like usual, meetings are hybrid where attendees can join in person or remotely. The meetings include task forces with leaders from Cimetrix on the GEM 300, ABFI (Advanced Backend Factory Integration), GUI, and DDA task forces as well as the committee meeting on Wednesday. This is a summary of what happened in the task forces including GEM 300, ABFI and DDA and other task force activities. There were few ballots this last cycle, but I will also include updates from the Fall meetings in 2024 since I did not create a blog for those meetings.

Note that all ballots that pass in the committee are still subject to a final review by the global SEMI Audit & Review committee, where a ballot technically can still fail when proper SEMI procedures and regulations are not strictly followed. This is rare in the North America Information & Control Committee but can happen.

I also wish to note that SEMI publishes a website with all global committee information where anyone can peruse the extensive details. It is at this website: https://www.semi.org/en/products-services/standards/developing-technical-standards.

GEM300 Task Force

The most recent changes to the GEM and GEM 300 standards include the addition of ‘well-known’ names for all required collection events, alarms, data variables, status variables and equipment constants within each standard. Recent ballots are related to fixing a few errors in these new tables and updates based on other ballots. This work is finally done for the core standards. Next step in this long process is to update the EDA (Interface A) E164 standard and new subordinate standard to require use of these well-knowns and also to update the SEMI E172 SEDD standard to require use of the well-known names in equipment SEDD files. This has taken a couple years to develop, but ultimately will be extremely useful to quickly map host software applications to implementations, both for EDA and GEM interfaces, and to identify GEM data in EDA implementations. Quicker mapping means quicker equipment integration at the factory.

Last fall, the GEM 300 task force passed some minor updates to the E90 substrate tracking standard in ballot 7278. This includes adding a couple new variables related to the substrate attributes not previously called out specifically yet were added more for completeness than usefulness. This winter, another E90 ballot 7316 passed that corrected a long existing spelling inconsistency for variables between E90 and E90.1. This should not affect implementations, yet some implementers may wish to rename a couple of variables in their implementations to match the standard.

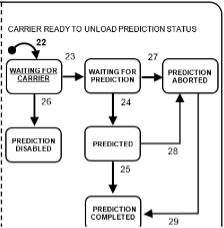

Last fall, the GEM 300 task force made similar changes to the E87 carrier management standard in ballot 7279. In addition to adding a few new well-knowns mapping to additional port and carrier attributes, the well-known names for alarms now support port specific alarms. Well-known names were added for the Carrier Complete Prediction state model, recently updated in 2024 with significant changes. Finally, the carrier’s substrate count attribute format was modified from a limiting 1-byte to allowing 4-byte implementations. This is an important improvement for the semiconductor backend industry where there can be hundreds of substrates on a carrier, unlike semiconductor front end where the substrates are typically wafers and limited to 25.

This winter an E157 Module Process Tracking ballot finally passed in its third attempt. This ballot significantly enhanced to support equipment that don’t have a process chamber. The current published standard focuses on reporting recipe execution in a process module, where all the material in the chamber is processed simultaneously. Most importantly, the standard enables reporting when each step in the recipe begins and completes. Many equipment in especially outside of semiconductor front-end don’t have a process module and instead have continuous flow operation. The enhancements to E157 enable reporting the recipe execution on a specific substrate, including when each step begins and completes. This is another example how GEM related standards are adopting to the needs of backend equipment.

Ballot 7312 replaced ballots 7275 and 7276 from the 2024 fall meetings to implement well-known names in SEMI E5, the SECS-II standard. The task force decided to rename E30 well-known names that originate in SEMI E5 with an ‘E5’ prefix instead of ‘E30’. This passed ballot completes the current plans to develop these well-known names in the GEM related standards.

DDA Task Force

Last fall, the DDA task force pass just one ballot. Ballot 7288 resolved a few issues raised by task force members and an update the .proto files to align with the current Protocol Buffers Style Guide. By conforming to the Protocol Buffers Style Guide, gRPC code generators can better adapt to language specific styles.

After the DDA task force met last fall, a group of companies volunteered to test the data collection features using the proposed gRPC interface definitions and updated E134 standard. Previous test sessions had already validated E132 Session Management and E125 Equipment Modeling. A test plan was created and previously distributed to the participants. Attendees alternated connecting with each other’s software as clients and servers and then collecting data. Five companies participated. Twenty-eight issues were submitted of varying severity. Based on this feedback, the DDA task force created ballot 7321 to correct known issues. Since then a few more issues have been reported. The task force ballot failed one of the ballot line items and will resubmit with corrections and a few additional changes for voting in the upcoming cycle. If all goes well, the changes in ballot 7321A will become the core of the EDA Freeze 3 standard. We can hope!

The DDA Task Force is also actively developing a ballot to update SEMI standard E164 which establishes EDA equipment modeling guidelines. New subordinate standards will map GEM 300 standards to a specific EDA freeze 3 implementation based on the well-known items recently defined in the GEM 300 standards and based on the updated primary standard E164 guidelines. This is the final piece to establishing a complete EDA Freeze 3 standard. Client and equipment server implementers can develop software before E164 is finalized.

ABFI (Advanced Backend Factory Integration) Task Force

No ballots were adjudicated in the ABFI task force. Instead, the task force continued several open discussions. We discussed how a ballot from last year was published as a new standard SEMI E192 Guide for Equipment Adoption Criteria for GEM and GEM-Related Standards. The guide was just published in January 2025 and aims to provide a high-level overview and organization of the 40+ GEM related standards and the GEM related 30+ subordinate standards. The guide is meant to introduce the many GEM related standards for newcomers and experts alike. Since the guide was written and now published, several developments have occurred which require the guide to be updated.

- The Computer and Device Security task force in the Information & Control Committee developed a new GEM-related standard, E191.

- The GEM 300 task force expanded the scope for E157 including a title change.

- The Equipment Data Publication task force in the Information & Control Committee developed a new GEM-related standard, E190.

A new ballot was approved to update the SEMI E192 guide with these latest changes.

Additionally, the ABFI task force is planning to update the SEMI E142 substrate map specification to include standardized XY coordinate system mapping.

CDS (Computer & Device Security) Task Force

The CDS task force is actively updated SEMI standard E191, the Specification for Computing Device Cybersecurity Status Reporting. This new standard defines standard status variables on a GEM interface regarding the operating system for each computer in the equipment, such as the name, version and build of the operating system. This enables factories to track the operating systems on the computers and compare this with any known vulnerabilities and request equipment computer patches and upgraded. The standard will be updated to provide more information, although the additional data is not yet completely decided.

Information & Control Committee

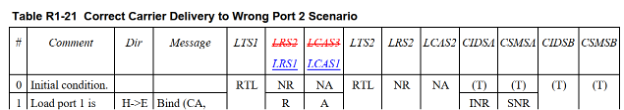

A new order of business was introduced in the Information & Control Committee by representatives from the Physical Interfaces and Carriers committee. Our two committees share control of the SEMI standard E84 the Specification for Enhanced Carrier Handoff Parallel I/O interface. Some users are interested in developing a new TCP/IP based protocol be introduced to replace the parallel I/O interface. The discussions are preliminary just seeking interested parties at this time.

To learn more about the SEMI standards, the committees or just to speak with an expert please click the button below.

Earlier this quarter (16-18 April 2024) Alan Weber and Jon Holt were privileged to deliver the 3-hour tutorial that always precedes the opening session of the annual European Advanced Process Control and Manufacturing (APC|M) Conference. This year’s conference was held in Hamburg, Germany and again co-located with the Smart Systems Integration (SSI) Conference and attracted more than 200 participants across the industry and around the globe.

Earlier this quarter (16-18 April 2024) Alan Weber and Jon Holt were privileged to deliver the 3-hour tutorial that always precedes the opening session of the annual European Advanced Process Control and Manufacturing (APC|M) Conference. This year’s conference was held in Hamburg, Germany and again co-located with the Smart Systems Integration (SSI) Conference and attracted more than 200 participants across the industry and around the globe. In a slight break with tradition, rather than diving deeply into one or two APC-specific technologies, Alan and Jon took a broader perspective, covering a wide range of topics that are germane to production implementations of APC and related advanced manufacturing applications. The rationale for this approach is that APC can no longer be considered a standalone suite of applications, but an integral part of an increasingly complex factory information and control system. As a result, APC practitioners should have at least a working knowledge of these necessary complementary technologies.

In a slight break with tradition, rather than diving deeply into one or two APC-specific technologies, Alan and Jon took a broader perspective, covering a wide range of topics that are germane to production implementations of APC and related advanced manufacturing applications. The rationale for this approach is that APC can no longer be considered a standalone suite of applications, but an integral part of an increasingly complex factory information and control system. As a result, APC practitioners should have at least a working knowledge of these necessary complementary technologies.

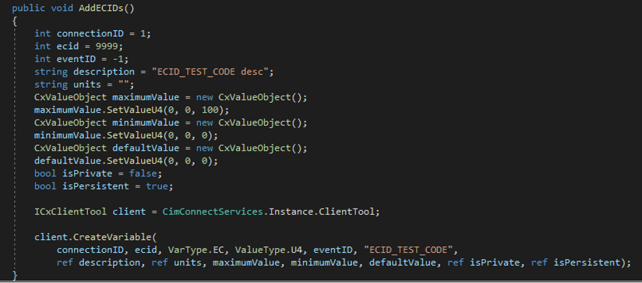

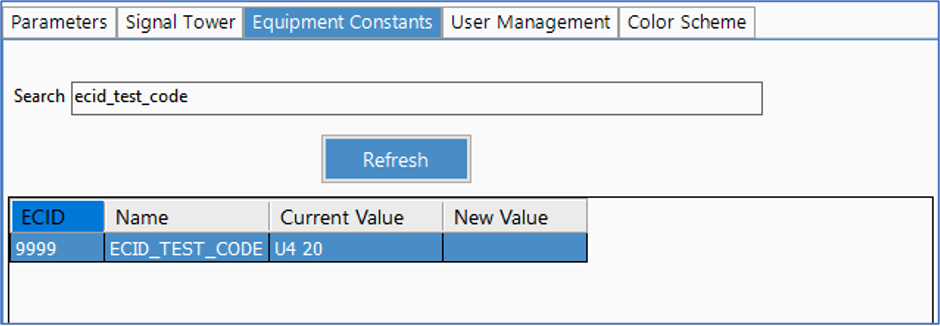

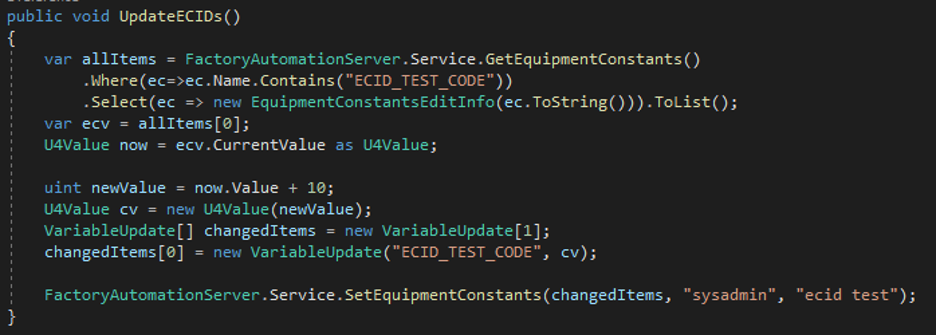

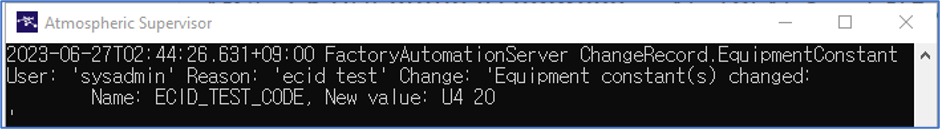

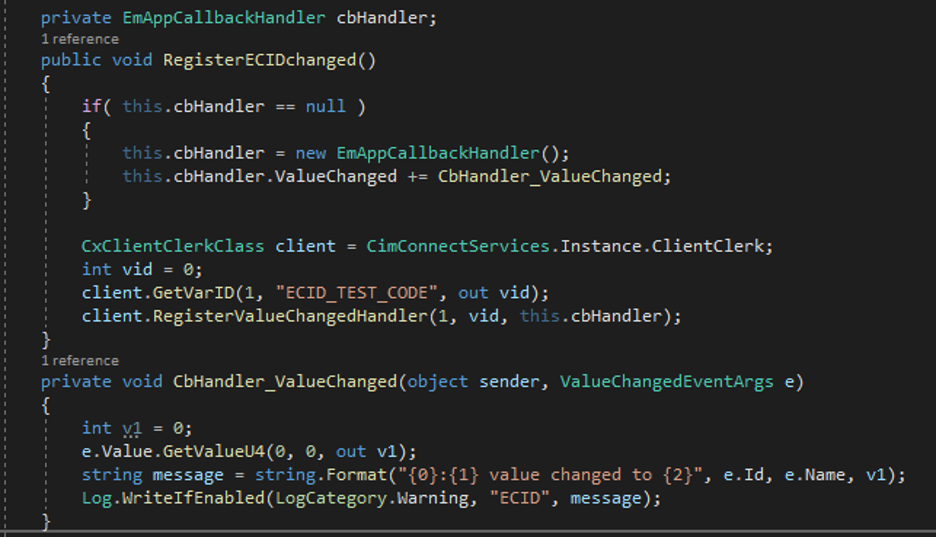

How to change the value of an ECV

How to change the value of an ECV

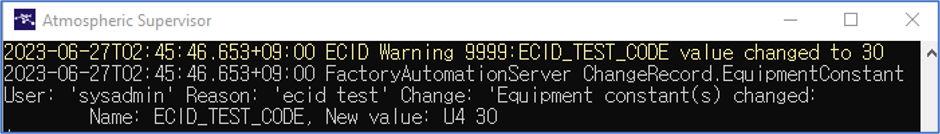

To Summarize:

To Summarize: