by David Francis

Product Manager

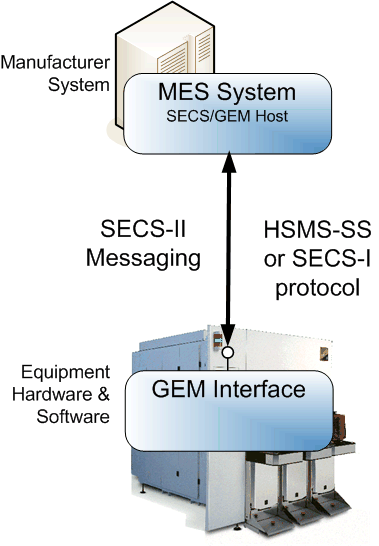

During SEMICON West last year, ISMI made a presentation about a proposed new standard: EDA Common Metadata. EDA stands for Equipment Data Acquisition and is also known as Interface A. The EDA Common Metadata was being balloted as SEMI Document number 5002. That initial ballot failed and so did the next attempt. However, recently, on the third attempt, document 5002B passed SEMI’s Information & Control Committee voting. While it still needs to pass the SEMI ISC Audits & Review Committee before it becomes an official SEMI standard, the 5002B ballot seems to be gaining support.

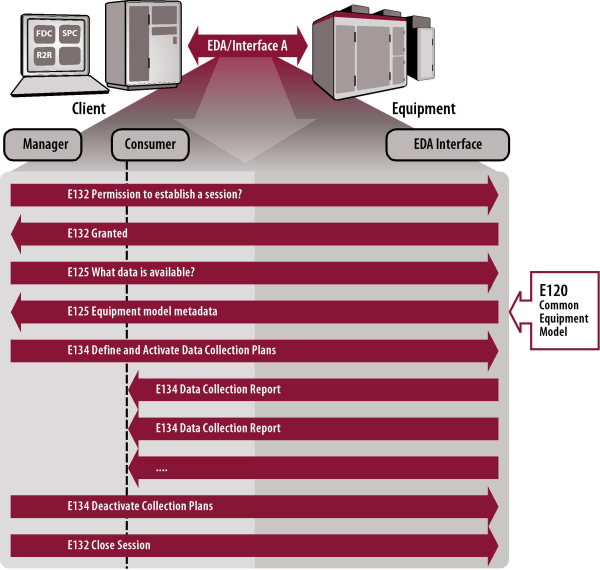

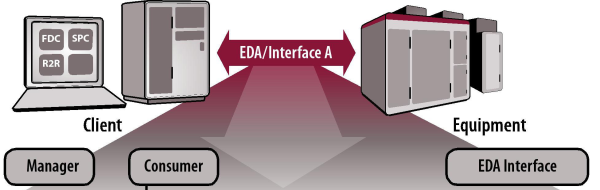

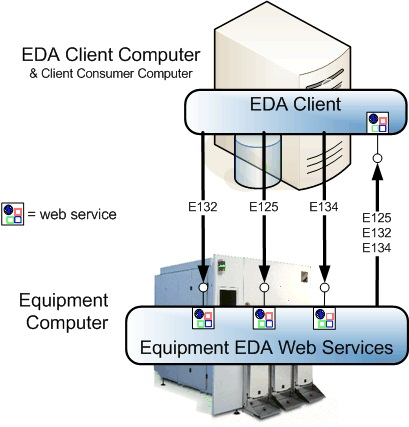

The SEMI E30, E40, E87, E90, E94, E116, E148, and E157 all define communication and behavior standards for semiconductor processing and metrology equipment. These standards produce the content of the EDA data. The E120, E125, E128, E132, E134, and E138 standards define how to establish and use web services that use SOAP/XML messages over HTTP or HTTPS to transfer data from the equipment to client applications.

So if all these standards already exist for defining EDA content, why was a Common Metadata necessary?

Although he wasn’t talking about SEMI Standards, I think Captain Barbosa in the movie Pirates of the Caribbean: The Curse of the Black Pearl captured the reason best when he said, “The code is more what you would call guidelines than actual rules.” Within the standards there is a lot of room for interpretation regarding the details of how they are implemented. The EDA Common Metadata establishes more specificity around the guidelines for how the equipment data should be represented. The goal is to improve the quality and consistency of the data provided through the EDA interface so that host-side client applications can make better use of the data.

In 2010, ISMI announced a new Freeze Version of the EDA standards known as Freeze Version 2 or the 0710 Freeze Version. This defined the specific version of each of the individual EDA standards that should be used by equipment manufacturers to create an EDA interface. For more about the freeze versions for EDA/Interface A, read the Cimetrix Introduction to SEMI EDA/Interface A Standards.

The new SEMI 5002B document provides a single, agreed, interpretation of the various SEMI standards as represented in a common metadata definition, which will help drive consistency in how the standards are implemented. The consistency that should result from the new Common Metadata will help remove some of the uncertainty that may have prevented many companies from developing host-side client applications that can use the EDA data produced by the equipment.

I have been a Scoutmaster for the Boy Scouts of America for about 5 years now. Our troop goes camping several times a year. Utah offers a lot of beautiful and interesting camping areas. The variety is remarkable. In our troop we spent a lot of time teaching and preparing the boys to not only have fun, but also be safe and wise in their fun. Some planning ahead, training and common sense can make a huge difference. Nearly every week, I have our Senior Patrol Leader help all of the scouts in our troop recite a number of memorized phrases including the Scout Oath, Law, Slogan, Motto and sometimes even the Outdoor Code. The Scout Motto is the famous one known to almost everyone in the world; "Be Prepared". Reciting it every week helps our minds to remember to focus on being prepared for whatever may come. We prepare the boys to handle emergency situations such as medical and weather related emergencies. "Be Prepared" applies not only to scouting activities like camping, canoeing and hiking, but also to school, our careers and everything we do.

I have been a Scoutmaster for the Boy Scouts of America for about 5 years now. Our troop goes camping several times a year. Utah offers a lot of beautiful and interesting camping areas. The variety is remarkable. In our troop we spent a lot of time teaching and preparing the boys to not only have fun, but also be safe and wise in their fun. Some planning ahead, training and common sense can make a huge difference. Nearly every week, I have our Senior Patrol Leader help all of the scouts in our troop recite a number of memorized phrases including the Scout Oath, Law, Slogan, Motto and sometimes even the Outdoor Code. The Scout Motto is the famous one known to almost everyone in the world; "Be Prepared". Reciting it every week helps our minds to remember to focus on being prepared for whatever may come. We prepare the boys to handle emergency situations such as medical and weather related emergencies. "Be Prepared" applies not only to scouting activities like camping, canoeing and hiking, but also to school, our careers and everything we do. Fabs are like people, each one has it own personality traits. Fortunately, and arguably unfortunately, unlike people, most fabs have a handbook for their “personalities” in the form of specifications. I have found it interesting, that like people, fab “personalities” have common and unique features. Here are a few of examples:

Fabs are like people, each one has it own personality traits. Fortunately, and arguably unfortunately, unlike people, most fabs have a handbook for their “personalities” in the form of specifications. I have found it interesting, that like people, fab “personalities” have common and unique features. Here are a few of examples: