Cimetrix and our new distribution partner, Linkgenesis, participated in a joint booth at SEMICON Korea last week in Seoul. With over four exhibit halls located in the COEX Convention and Exhibition Center, SEMICON Korea is the largest SEMICON in terms of number of visitors—about 40,000—and included over 1,870 booths in 36,000 sq. meters of show space. The theme of the show was “Connect to Future, Market, People and Technology” with keynote speakers from leaders at Synopsys, Texas Instruments, and Audi. The show was co-located with LED Korea. Included in the schedule was also a meeting for the Information and Control Technical Committee, Korea Chapter, to work on SEMI standards.

Cimetrix and our new distribution partner, Linkgenesis, participated in a joint booth at SEMICON Korea last week in Seoul. With over four exhibit halls located in the COEX Convention and Exhibition Center, SEMICON Korea is the largest SEMICON in terms of number of visitors—about 40,000—and included over 1,870 booths in 36,000 sq. meters of show space. The theme of the show was “Connect to Future, Market, People and Technology” with keynote speakers from leaders at Synopsys, Texas Instruments, and Audi. The show was co-located with LED Korea. Included in the schedule was also a meeting for the Information and Control Technical Committee, Korea Chapter, to work on SEMI standards.

Korea remains the second largest equipment market for the second year in a row, and represents the largest region of installed 300mm fab capacity in the world. This show has more equipment manufacturers, in my opinion, than most SEMICON shows. So, because of the show’s location, it made it an ideal opportunity for us to meet with our current worldwide equipment manufacturing customers who seemed to be present in every row, and to meet the growing list of Korean equipment manufacturers as they build volume and increase their expertise. We already have several customers in Korea and expect this number to grow over the next few years.

Our new partnership with Linkgenesis was founded on providing EDA/Interface A solutions in Korea; currently Samsung and Hynix are both looking at incorporating this technology into their manufacturing systems. As the world leader in EDA/Interface A, Cimetrix can provide superior expertise to make the adoption process efficient and successful. Linkgenesis already has business with most Korean equipment manufacturers, so, by combining forces, we bring strong local engineering support together with our world-class EDA solution, CIMPortal™ Plus.

To accelerate our penetration into Korea, we have hired Mr. Hwal Song (+82 (0) 10-5058-0895) as our Korean General Manager to accelerate our customer introductions and partnership with Linkgenesis. Song has a long history in the semiconductor software industry.

We met with several new potential customers during the show setting a strong foundation for our continued growth in the Korean market. We left the show feeling very positive about Cimetrix’ entry into Korea.

At the Information and Control Technical Committee meeting, David Francis, Director of Product Management, represented Cimetrix. In the meeting there was an introduction to work being done by SEMI Japan related to Role Based Access Control (RBAC); however, this effort is still under development by the Japan Task Force. The North America DDA Task Force is starting discussions about Freeze 3 of the EDA Standards. Tom Salmon, Vice President Global Member Services and Standards, introduced information about the SEMI Automation Technology Committee that is working on the Smart Manufacturing initiate in support of efforts coming out of Industrie 4.0 and Industrial Internet Consortium. There was also an information share on the status of efforts around standards for Recipe Management Systems that address some of the concerns with the existing standards such as Recipe and Parameter Management (RaP).

SEMICON Korea 2016 as a whole was a success for both Cimetrix and the Korean semiconductor industry. Seoul was a great backdrop for the show and we look forward to returning next year with greater market penetration and the chance to catch-up with even more clients.♦

To be contacted about Cimetrix' CIMPortal Plus or any of our products and/or services, please click here.

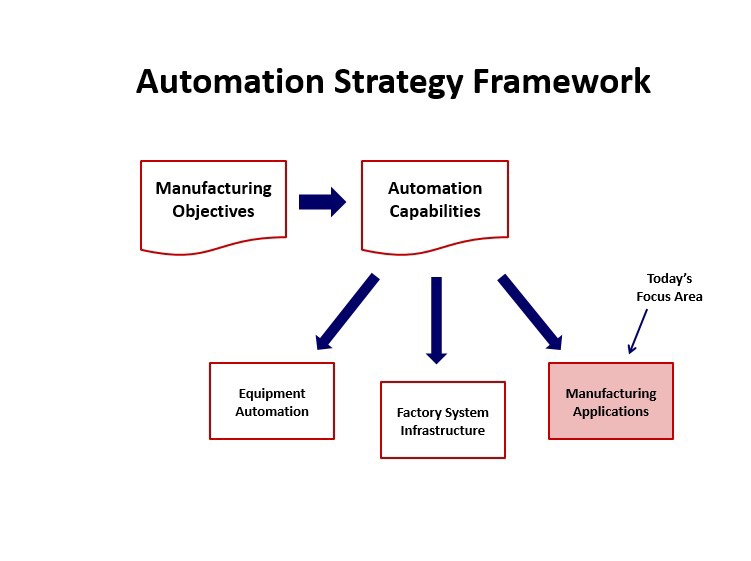

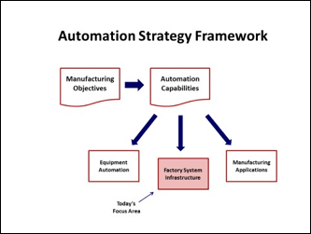

However, before diving into a detailed design process for an EDA factory system, you must decide what overall system architecture will govern that design. A number of factors go into this decision, including 1) the functional requirements that distinguish EDA-based data collection from other more traditional approaches, 2) technology constraints of the existing factory systems, 3) budget limitations, 4) schedule requirements, and especially 5) the non-functional requirements (scalability, performance, reliability, ease-of-use, etc.) that often make the difference between success and failure of a given system.

However, before diving into a detailed design process for an EDA factory system, you must decide what overall system architecture will govern that design. A number of factors go into this decision, including 1) the functional requirements that distinguish EDA-based data collection from other more traditional approaches, 2) technology constraints of the existing factory systems, 3) budget limitations, 4) schedule requirements, and especially 5) the non-functional requirements (scalability, performance, reliability, ease-of-use, etc.) that often make the difference between success and failure of a given system.