by Matt Mayer,

Principal Software Engineer, Global Services

- Establishing Communication- A standardized communications mechanism ensures both equipment and host have agreed, and all requirements necessary for properly collaborating data (between tool and host) based on the SEMI® SECS messaging standards (E5) are compatible during the connected status and after connection could have been disrupted.

-

Spooling- Spooling is an essential part of keeping synchronization with the tool. Communications (connect status) can be disrupted. In the event of communication disruption, the tool can be configured to spool collection event (S6F11) messages after communications has been restored and the host requests the last know transactions for the lost time span.

Spooling can be configured to retain a SECS message pooled history of almost any stream and function (SEMI E5 standard). With this enriched functional capability, any condition of the tool can be relayed at anytime after communication has been re-established (e.g.: alarms, events, processing state changes, etc…).

With that said about spooling, the host is required to take special care of the data received and re-act to the latest available data (spooled messages) in the most appropriate manner. In many cases, this behavior of the host takes special care at documentation and tool manufacturer collaboration.

-

Alarm Handling- The alarm handling capability provides for host with notifications and management of alarm conditions occurring on the equipment. Typically an alarm is associated with abnormal conditions of the equipment.

With each alarm a correlating set/clear event notification will be issued to the host. As with each event definition, a report can be defined and linked in order to associate variable data specific to the alarm (see Event Handling).

-

Event Handling- Event handling provides a dynamic and flexible method for the tool manufacturer to customize the equipment to meet needs specified by the fabrication facilities with respect to data representation and presentation to the host. The event based approach to data collection provides automatic notification to the host and its activities which are useful in monitoring the equipment and in maintaining synchronization with the equipment.

Reports can be configured by the host application and attached to event report messages (S6F11). These reports are linked to the desired event and are typically associated with variable data relating to the event generated by the equipment.

-

Variable Handling- The variable handling capability provide both the tool and equipment the ability to share details. Variables are categorized in three groups.

Groups:

- Equipment Constants, provides the capability for the host to read and change the value of selected variables of type EC which allow the host to reconfigure the variety of equipment functionality.

- Status data, the values of a status variable will be current.

- Discrete data, the values of DVs are only guaranteed to be valid at the occurrence of a collection event.

-

Process State Model Handling- The processing state model is dependent on the equipment process and technology. However, there are expected common aspects to these models. Many of these equipments use the GEM proposed state model with some variations. An ERROR and MANUAL state can be utilized during initialization and when the state is idle.

Based on the SEMI E30 standard, the equipment must generate collection events for each processing state transition, as well as provide status variables (ProcessState, PreviousProcessState) which values represent the current processing state and the previous processing state. Other collection event reports can be defined and linked to event triggers.

-

Remote Command Handling- The capability which provides the host with control over the equipment and its operations. A remote command consists of parameter name/value pair with a particular host command (S2F41). The equipment manufacturer will provide unique names for any supported command parameters. The command parameters are defined by fabrication facilities and equipment manufacturers.

A typical set of remote commands are listed below. However, the list is not a constraint and any set of remote commands can be specified and used.

- PPSELECT

- START

- STOP

- PAUSE

- ABORT

-

Recipe Upload/Download Handling- Recipe handling provides the means for transferring process (recipe) information between the host and the equipment. The specifications for equipment processing (e.g. recipes) are managed through SECS messages (E5). Recipe uploading and downloading will be accomplished using several formats and combination thereof.

Formats:

- Unformatted recipe content

- Formatted recipe content

- Value based content transfer

- File based content transfer

In addition to the above mentioned considerations, Cimetrix's CIMConnect, an object-oriented software development kit for equipment suppliers to quickly develop a GEM interface, also allows for multi-host connections.

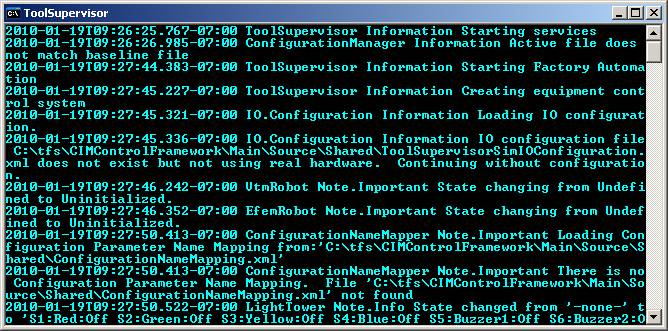

In today’s world, having great software is not enough. To be successful, software must also be supportable. Keeping a record of what the software is doing and has done enables after-the-fact diagnosis and makes remote support much more efficient. As an additional benefit, this information can also be displayed live to the GUI, giving the operator additional insight into what is happening. Having a record makes it possible to determine if the software is working correctly or incorrectly. In Cimetrix’s new tool control software, CIMControlFramework™, this functionality is provided by the Logging package.

In today’s world, having great software is not enough. To be successful, software must also be supportable. Keeping a record of what the software is doing and has done enables after-the-fact diagnosis and makes remote support much more efficient. As an additional benefit, this information can also be displayed live to the GUI, giving the operator additional insight into what is happening. Having a record makes it possible to determine if the software is working correctly or incorrectly. In Cimetrix’s new tool control software, CIMControlFramework™, this functionality is provided by the Logging package. Cimetrix and Rorze have been working together for several years with Rorze transitioning the FA for its Sorter line to Cimetrix

Cimetrix and Rorze have been working together for several years with Rorze transitioning the FA for its Sorter line to Cimetrix  by Stephanie Sampson,

by Stephanie Sampson,