Background

In a few previous blogs I shared how the relatively new SEMI Advanced Backend Factory Integration (ABFI) task force in North America has already decided to promote the adoption of the GEM standard and selective adoption of the GEM300 equipment communication standards. In this blog I will summarize the task force’s plans to consider adoption of additional SEMI information and control standards that are complementary to GEM and GEM300.

Additional SEMI Standards for the Backend Consideration

Many of the standards listed below were developed a few years after GEM300 but are now considered to be part of the modern GEM300 set.

|

SEMI Designation

|

Standard Name

|

|

E84

|

Specification for Enhanced Carrier Handoff Parallel I/O Interface

|

|

E116

|

Specification for Equipment Performance Tracking

|

|

E116.1

|

Specification for SECS-II Protocol for Equipment Performance Tracking (EPT)

|

|

E142

|

Specification for Substrate Mapping

|

|

E142.1

|

Specification for XML Schema for Substrate Mapping

|

|

E142.2

|

Specification for SECS-II Protocol for Substrate Mapping

|

|

E148

|

Specification for Time Synchronization and Definition of the TS-Clock Object

|

|

E157

|

Specification for Module Process Tracking

|

|

E172

|

Specification for SECS Equipment Data Dictionary (SEDD)

|

|

E173

|

Specification for XML SECS-II Message Notation (SMN)

|

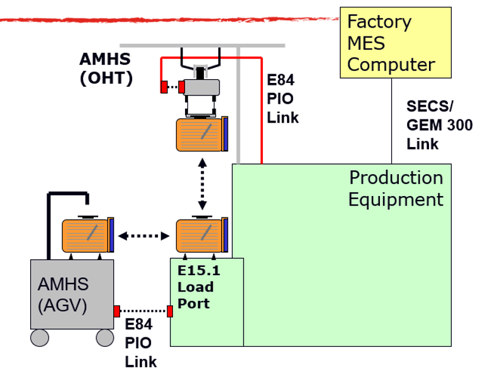

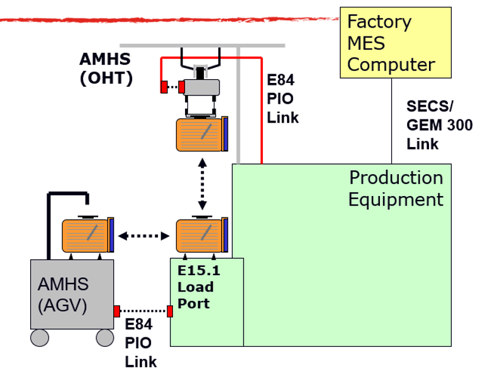

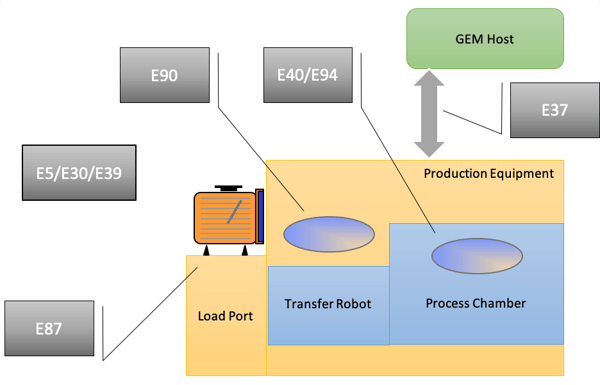

E84 Carrier Handoff

E84 Carrier Handoff is the only standard in this list that not a GEM standard because it deals with a separate parallel I/O interface. This interface is completely independent of GEM, although it is coordinated with E87 Carrier Management when both are supported. However, since E84 Carrier Handoff is often included in the GEM300 discussions and requirements, it is worth discussing here because it is a standard that the Backend industry should selectively adopt.

The E84 standard defines the handshake signals for use in a parallel I/O (PIO) interface to automate carrier delivery and carrier removal. The automated material handling system (AMHS) might use either an automated guided vehicle (AGV) or overhead transport (OHT) system, yet either way, the material is delivered in a carrier. E84 is widely used and accepted in every semiconductor wafer fab (front end) and an obvious choice for backend manufacturing when delivering carriers.

E116 Specification for Equipment Performance Tracking

E116 Equipment Performance Tracking was discussed in an earlier blog since there are plans to update this specification to better support backend operations. E116 is applicable to any manufacturing equipment in any industry because it is largely based on SEMI E10 principles which define generic terms for measuring any equipment’s reliability, availability and maintainability. As a bonus, each major component in the equipment can also be modelled to track its productivity.

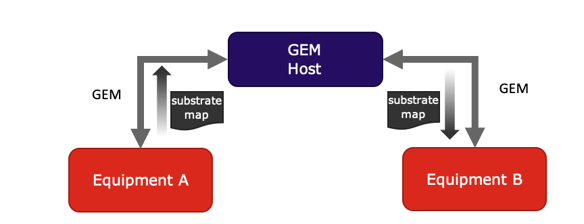

E142 Specification for Substrate Mapping

E142 Substrate Mapping and its subordinate standards (E142.1 XML Schema for Substrate Mapping and E142.2 SECS-II Protocol for Substrate Mapping) define generic substrate maps and how to transfer them to and from an equipment through a GEM interface. Substrate maps are two dimensional arrays of data that correspond to a physical substrate—which may be a wafer, strip or tray. The map defines the dimensions of the substrate, significant locations on the substrate, and can include data about the locations (such as a numbering scheme for unambiguously identifying specific locations). For example, E142 can be used to tag “known good” devices on a substrate.

Some equipment types require a substrate map before processing can proceed. Some equipment can generate substrate maps. And some equipment both require a substrate map before processing and generate an updated substrate map after processing is completed. In E142, the substrate map is expressed in an XML file that conforms with the E142 XML schema. A lot of backend equipment need substrate maps for normal operation, so E142 is an obvious choice. Note that E142 is currently undergoing some interesting improvements via the ABFI task force to store additional data needed to address enhanced traceability requirements.

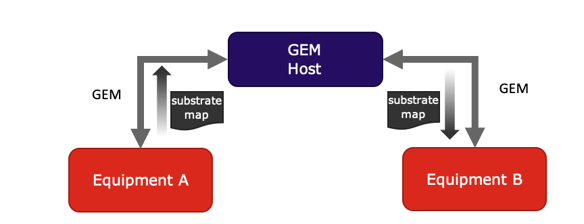

Substrate mapping is an excellent demonstration of horizontal communication implemented using GEM. Horizontal communication is when data is shared directly from one equipment to another equipment. Traditionally, horizontal communication in GEM is implemented indirectly; one equipment passes data to the host and then the host passes that data on to the equipment that needs it. In this sense, the GEM host acts as a type of broker between units of equipment.

There are significant advantages in using this indirect style of horizontal communication. For example, Equipment A might inspect a substrate, generate a substrate map and send it to the host. Equipment B might later request the substrate map from the host.

The benefit of using a GEM host between the equipment to realize this use case is that both Equipment A and Equipment B are only required to implement GEM—which they should be doing anyway. The equipment are not required to support additional protocols and/or custom message sequences, or to be tested against specific equipment interfaces. If each equipment follows the GEM standard, they can all be integrated into the factory system and share data through the GEM host.

The benefit of using a GEM host between the equipment to realize this use case is that both Equipment A and Equipment B are only required to implement GEM—which they should be doing anyway. The equipment are not required to support additional protocols and/or custom message sequences, or to be tested against specific equipment interfaces. If each equipment follows the GEM standard, they can all be integrated into the factory system and share data through the GEM host.

E148 Specification for Time Synchronization and Definition of the TS-Clock Object

A lot of data collected in the factory is only useful when properly timestamped. Moreover, timestamps can only be compared among data from multiple sources when those timestamps are synchronized. This is where SEMI E148 enters the picture.

The E148 Time Synchronization specification requires equipment to support the industry standard Network Time Protocol (NTP) and share information about its implementation. And NTP software synchronizes computer clocks.

Because the backend industry segment is trending towards more and more data collection, it is critical to have proper timestamping for that data, and therefore time synchronization for its sources. A full E148 implementation may not be required, but certainly the equipment should support NTP as described in E148. If an equipment control systems is composed of multiple computers, E148 states that they should all be synchronized with a single computer designated as the master, which is a good idea if the other computers are generating data with timestamps.

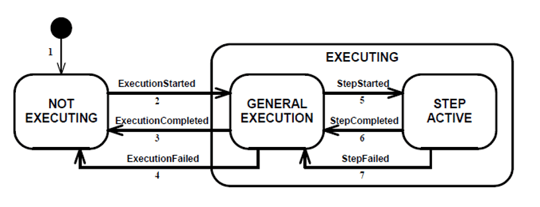

E157 Specification for Module Process Tracking

E157 Module Process Tracking does not apply to all backend equipment. To use E157 Module Process Tracking, there must be at least one process module (aka a process chamber) which processes one substrate or a batch of material at a time. If multiple substrates are processed at a time but each having different start and stop times, then this specification cannot be applied.

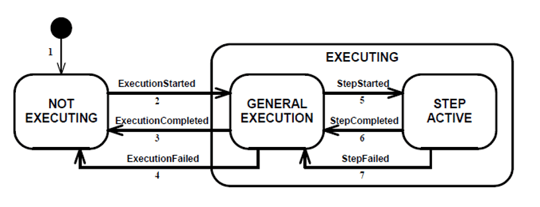

E157 Module Process Tracking defines a very simple processing state model which is implemented independently for each process chamber.

The state model reports when the process chamber is either idle (Not Executing) or processing a recipe (Executing). And when processing a recipe, each time an individual step in the recipe starts, completes, or fails, this is reported. It is up to the implementer to decide what constitutes a recipe step. In my experience, most equipment that could adopt E157 have already implemented something very similar using a set of GEM events. However, rather than implementing something custom, it is better for end users and equipment manufacturers alike if the implementations are standardized.

The state model reports when the process chamber is either idle (Not Executing) or processing a recipe (Executing). And when processing a recipe, each time an individual step in the recipe starts, completes, or fails, this is reported. It is up to the implementer to decide what constitutes a recipe step. In my experience, most equipment that could adopt E157 have already implemented something very similar using a set of GEM events. However, rather than implementing something custom, it is better for end users and equipment manufacturers alike if the implementations are standardized.

E157 is a prime example of an exceptionally simple and well-written standard built on top of GEM technology that is easy to implement and provides a lot of end user value. Hopefully the ABFI task force can develop something based on E157 principles that is well suited for backend equipment that cannot accommodate the full scope of the current standard.

E172 Specification for SECS Equipment Data Dictionary (SEDD)

Go back in time (not that far, actually), and “GEM documentation” meant a stack of printed documentation on paper that was expected to be delivered with the equipment. Today “GEM documentation” means an MS Word document, PDF file, Excel spreadsheet, or some other electronic representation of the same information. Nearly any digital format is acceptable.

Nevertheless, E172 SECS Equipment Data Dictionary is the future of GEM documentation. The GEM documentation is provided in a standardized electronic XML format called an SEDD file. E172 defines a standard XML schema. The initial version of this schema included only basic information about a GEM interface. This was expanded in a later version to include several more details. Soon, I hope to report that the E30 GEM standard has been modified to officially include SEDD files as one form of documentation. Additionally, this should include enhancing the GEM standard to allow an SEDD file to be transferred directly through the GEM interface. This will significantly improve GEM’s plug-and-play capability by enabling factory host software to consume an SEDD file and automatically configure the GEM host software to support an equipment’s specific implementation of GEM and GEM messages.

As the backend industry segment is increasingly implementing GEM in its factories, I expect SEDD files to be required from all backend equipment manufacturers.

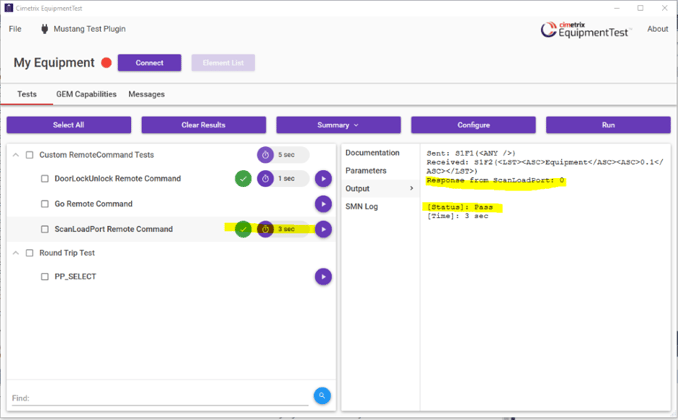

E173 Specification for XML SECS-II Message Notation (SMN)

In order to diagnose problems in a GEM interface, it is essential to have logging for the GEM messages transferred between the host and equipment. Typically, both the GEM host and equipment’s GEM interface will provide logging functionality. In the past, a notation called SML (SECS Message Language) was used for logging GEM messages. Unfortunately, SML was never standardized or even sufficiently well defined. As result, there are many different variations of SML throughout the world. While SML notation itself is relatively easy to generate with software, the breadth of implementation variations makes it difficult to automatically parse and use.

Fortunately, the SEMI North America GEM300 task force created E173 XML SECS-II Message Notation (SMN) to solve this problem. SMN defines an XML schema that anyone can use to document and log GEM SECS-II messages. The schema is feature rich allowing for both minimum and elaborate XML decoration. As an example of its usefulness and flexibility, the E172 SEDD schema references the SMN schema file. Because SMN is based on XML, it is both very easy for software to generate and consume. There are numerous software tools and libraries available in virtually every software programming language for working with XML. Using SMN with GEM allows GEM to continue to send and receive messages in an efficient binary format, yet still enjoy the benefits of using a decorated, human-readable text notation for diagnosing issues.

I expect the ABFI task force to recommend that the backend industry segment adopt SMN in all equipment GEM interfaces.

Conclusion

As backend factories adopt GEM, we expect that they will also want to use the latest technologies with it, including SMN, SEDD, Module Process Tracking and Equipment Performance Tracking. Watch for more details and updates from the SEMI Advanced Backend Factory Integration task force as its work progresses—and feel free to join this initiative if you want to help steer and accelerate this activity!

To download the GEM300 White Paper, click the button below.

.png?width=164&name=MicrosoftTeams-image%20(21).png) Cimetrix is pleased to announce and welcome Thomas Simon as its Director of Sales of Cimetrix Europe and Managing Director of Cimetrix GmbH. Thomas is based in Munich, Germany and will lead our growth in Europe. Thomas Simon will be responsible for ensuring the success of our growing customer base of leading semiconductor equipment manufacturers and smart manufacturing factories in Europe, providing strategic direction for Cimetrix Europe to have long-term success in the European market, overseeing local sales and account management and leading an expert team of Europe-based software engineers.

Cimetrix is pleased to announce and welcome Thomas Simon as its Director of Sales of Cimetrix Europe and Managing Director of Cimetrix GmbH. Thomas is based in Munich, Germany and will lead our growth in Europe. Thomas Simon will be responsible for ensuring the success of our growing customer base of leading semiconductor equipment manufacturers and smart manufacturing factories in Europe, providing strategic direction for Cimetrix Europe to have long-term success in the European market, overseeing local sales and account management and leading an expert team of Europe-based software engineers.

The benefit of using a GEM host between the equipment to realize this use case is that both Equipment A and Equipment B are only required to implement GEM—which they should be doing anyway. The equipment are not required to support additional protocols and/or custom message sequences, or to be tested against specific equipment interfaces. If each equipment follows the GEM standard, they can all be integrated into the factory system and share data through the GEM host.

The benefit of using a GEM host between the equipment to realize this use case is that both Equipment A and Equipment B are only required to implement GEM—which they should be doing anyway. The equipment are not required to support additional protocols and/or custom message sequences, or to be tested against specific equipment interfaces. If each equipment follows the GEM standard, they can all be integrated into the factory system and share data through the GEM host. The state model reports when the process chamber is either idle (Not Executing) or processing a recipe (Executing). And when processing a recipe, each time an individual step in the recipe starts, completes, or fails, this is reported. It is up to the implementer to decide what constitutes a recipe step. In my experience, most equipment that could adopt E157 have already implemented something very similar using a set of GEM events. However, rather than implementing something custom, it is better for end users and equipment manufacturers alike if the implementations are standardized.

The state model reports when the process chamber is either idle (Not Executing) or processing a recipe (Executing). And when processing a recipe, each time an individual step in the recipe starts, completes, or fails, this is reported. It is up to the implementer to decide what constitutes a recipe step. In my experience, most equipment that could adopt E157 have already implemented something very similar using a set of GEM events. However, rather than implementing something custom, it is better for end users and equipment manufacturers alike if the implementations are standardized.

Meet Anderson, a member of our Solutions Engineering team. Anderson lives and works in South Korea, and is an integral part of our Korea office. Read on to learn a little bit more about Anderson.

Meet Anderson, a member of our Solutions Engineering team. Anderson lives and works in South Korea, and is an integral part of our Korea office. Read on to learn a little bit more about Anderson.

Meet Rich Kingsford

Meet Rich Kingsford

Meet Brent Forsgren, the Director of CCF Services at Cimetrix. Read on to learn a little bit more about Brent.

Meet Brent Forsgren, the Director of CCF Services at Cimetrix. Read on to learn a little bit more about Brent.