We’re drowning in data but still thirsting for wisdom… This is a paraphrase of what one of the virology doctors interviewed at the beginning of the COVID-19 pandemic said about the challenges they faced in charting a course of action using the myriad volumes of data being collected around the world. The sentiment reminded me that in an entirely separate but no less complex domain: electronics manufacturers face similar challenges using data from the thousands of disparate sources in a factory to make the decisions that ultimately determine the viability of their enterprises.

We’re drowning in data but still thirsting for wisdom… This is a paraphrase of what one of the virology doctors interviewed at the beginning of the COVID-19 pandemic said about the challenges they faced in charting a course of action using the myriad volumes of data being collected around the world. The sentiment reminded me that in an entirely separate but no less complex domain: electronics manufacturers face similar challenges using data from the thousands of disparate sources in a factory to make the decisions that ultimately determine the viability of their enterprises.

To the extent that these two domains have a similar problem statement, they also share a set of solution technologies. Among them is Machine Learning (ML), which is a promising subset of Artificial Intelligence (AI). The essence of Machine Learning is using data collected from past events to develop and train a model that can make reliable predictions about the outcome of future, as-yet-unseen events.

Machine Learning technology is already more ubiquitous than you might imagine. For instance, if you’ve ever 1) ordered one of Amazon’s product recommendations based on your previous purchases and search history, 2) seen the names on the faces of people in your photo library (and updated the ones it got wrong), 3) rated your satisfaction with a Netflix movie you’ve just watched, or 4) interacted with one of the language translation apps on your smart phone, congratulations—you are now an integral part of the Machine Learning ecosystem of the suppliers of those everyday products.

Beyond these familiar examples, two factors have contributed to the rapid ascendance of ML as a viable production technology: the availability of massive amounts of data and affordable storage and processing power to analyze it. As a result, Machine Learning is now seen as a key enabling technology for Smart Manufacturing in multiple industries and at multiple positions along the value chain.

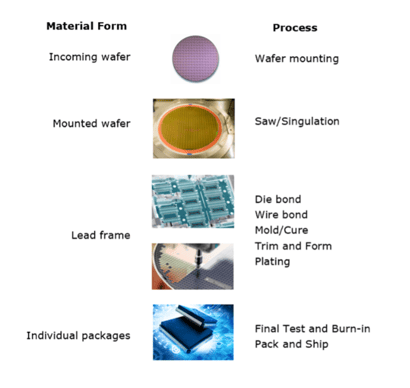

Documented use cases in semiconductor front-end factories include production scheduling and dispatching, process analysis and excursion prediction, equipment FDC (fault detection and classification), preventive maintenance, failure prediction, trace data analysis, and so on. Equipment suppliers are likewise looking for ways to add value to their products by offering ML-based capabilities as an option. Semiconductor back-end and SMT factories and their respective equipment suppliers are also actively evaluating ML technologies. These instances all have one thing in common: the need for quality equipment data… and lots of it.

Two of the most prevalent approaches to Machine Learning are 1) supervised learning, which uses labelled data samples to develop a model that predicts the labels for future samples; and 2) unsupervised learning, which can use unlabeled data samples to develop a model of expected behavior that can predict deviations from that behavior for future samples.

Both categories have direct applications in manufacturing and include a range of specific algorithms that may be suited to various problem types. The trick is knowing which technique(s) to apply in which situations, and once chosen, how to tune a particular technique for a given problem.

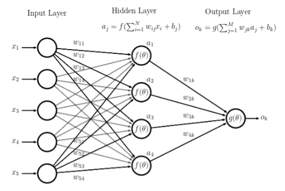

One category of public-domain algorithms that has shown significant promise for commercial applications has been labelled “Deep Learning,” and it refers to a variety of “Artificial Neural Net” approaches. These algorithms fall into the supervised learning category but can nevertheless be applied in situations where the labels are not known a priori (e.g., analyzing system log files to detect anomalous behavior).

A frequently-cited candidate for a supervised learning algorithm is predictive maintenance, which uses as input a high-dimensional (i.e., lots of parameters) trace vector of equipment parameters with a binary label (“good” or “failed”). With enough production history this data can be used to train and validate a failure prediction model that would improve on the “run to fail” or “just in case” maintenance strategies used today.

Likewise, a good candidate for unsupervised learning is anomaly detection using equipment log file data (could also include trace data) as input. Many equipment suppliers save this kind of data for “after the fact” analysis of problems that occur in manufacturing without a clear sense of what might be useful. Deep Learning algorithms are particularly adept at using high dimensional data to create complex mathematical models that represent “normal” behavior and can be used to flag “abnormal” behavior as it happens.

From an implementation standpoint, there is no “one size fits all” Machine Learning package or library that can address the full range of potential opportunities. Moreover, since Machine Learning is only a component (albeit a vital one) of an overall solution system, it is important to understand how all the pieces fit together when considering these technologies for a specific problem. Subsequent posts in this series will explore these topics in greater detail, so stay tuned for additional information about how to map these new technologies into your product and problem space. However, if your need is more urgent, click the button below to see how we can explore this exciting new area together.

For the first time since the Fall of 2019, the SEMI North America Information & Control Committee (I&CC) was finally able to meet and conduct business online. Throughout all of 2020, the I&CC was not able to meet because SEMI regulations did not at that time allow voting in online meetings. Instead, only the task forces have been meeting. As a result, any passing ballots, unless super clean, had to wait for adjudication in the North America I&CC.

For the first time since the Fall of 2019, the SEMI North America Information & Control Committee (I&CC) was finally able to meet and conduct business online. Throughout all of 2020, the I&CC was not able to meet because SEMI regulations did not at that time allow voting in online meetings. Instead, only the task forces have been meeting. As a result, any passing ballots, unless super clean, had to wait for adjudication in the North America I&CC.

Updated samples

Updated samples Near the end of January for almost two decades, the companies that form the Automation Network Dresden (AND) have hosted a gathering of semiconductor automation professionals in the picturesque setting of Dresden, Germany. The chill of winter during this event has always been in stark contrast to the warmth of the reception the speakers and participants enjoy at this event. The big question this year was “how could the organizers possibly maintain this tradition amid the COVID-19 pandemic and its travel restrictions?"

Near the end of January for almost two decades, the companies that form the Automation Network Dresden (AND) have hosted a gathering of semiconductor automation professionals in the picturesque setting of Dresden, Germany. The chill of winter during this event has always been in stark contrast to the warmth of the reception the speakers and participants enjoy at this event. The big question this year was “how could the organizers possibly maintain this tradition amid the COVID-19 pandemic and its travel restrictions?"

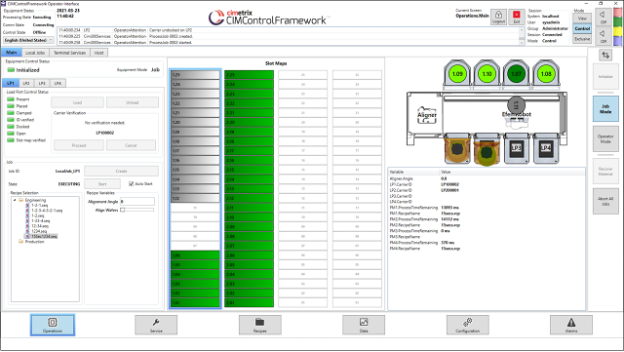

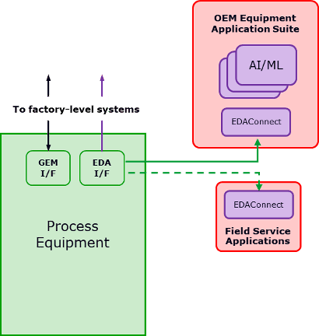

The EDA standards also include a provision for “built-in DCPs” (DCP = Data Collection Plan) which can be shipped with the equipment and protected from accidental deletion at the factory site. These DCPs could be crafted by the equipment supplier to directly feed whatever value-added applications the supplier chose to develop, whether these resided on a computer local to the equipment in the fab, on portable computers used by field service engineers to diagnose problems, or on remote cloud-based systems allowed to connect via secure EDA-defined URLs. This flexibility opens up a wide range of application types, from those that embed equipment-specific algorithms to generic Machine Learning frameworks… the possibilities are endless.

The EDA standards also include a provision for “built-in DCPs” (DCP = Data Collection Plan) which can be shipped with the equipment and protected from accidental deletion at the factory site. These DCPs could be crafted by the equipment supplier to directly feed whatever value-added applications the supplier chose to develop, whether these resided on a computer local to the equipment in the fab, on portable computers used by field service engineers to diagnose problems, or on remote cloud-based systems allowed to connect via secure EDA-defined URLs. This flexibility opens up a wide range of application types, from those that embed equipment-specific algorithms to generic Machine Learning frameworks… the possibilities are endless.