At Cimetrix, we are always looking to improve the customer experience. We also are constantly looking for means for improving efficiency and – especially this year – cutting costs.

At Cimetrix, we are always looking to improve the customer experience. We also are constantly looking for means for improving efficiency and – especially this year – cutting costs.

Well, all three of these objectives converge in our decision to implement a new phone system. We chose to go with a hosted VoIP system. Not only is this the most cost efficient option, it also allows for flexibility – integrating email, faxing, conferencing, and voice mail into one application. Internally, it allows us to more efficiently manage incoming calls, make employees more productive and reduce the wait time callers experience to be connected to their desired party.

From a customer’s perspective, this also means:

- Since users can take their VoIP adapters everywhere, Cimetrix team members are available while traveling at the same number that you would reach them while at the office.

- With call forwarding and call following capabilities, your single call gets routed to the desired party regardless of whether or not he/she is at the office.

- After hours, you will be provided a dial-by-name directory so that you can leave a message for a specific Cimetrix staff member. Also, for those employees that choose to route their calls outside of normal business hours, you may be able to reach the desired individual outside of the office.

Please note that the Cimetrix main offices will be closed on Thursday and Friday this week to celebrate the Thanksgiving holiday. However, with the new phone system in place, you will be able to dial-by-directory to leave a message for a specific employee and/or for those that have chosen to route calls to their home or cell phone, may be able to still reach specific staff members.

We hope that callers have a more pleasant experience with this new system in place and welcome any feedback. Please direct questions and comments to deann.rowan@cimetrix.com.

… and Happy Thanksgiving!

You might be thinking, “What does healthcare costs have to do with a factory automation and equipment control software solutions company?” Well, directly, not much but indirectly, it’s one of many benefits that play a role in retaining and attracting talented employees.

You might be thinking, “What does healthcare costs have to do with a factory automation and equipment control software solutions company?” Well, directly, not much but indirectly, it’s one of many benefits that play a role in retaining and attracting talented employees. I have a lot of children—seven. Many of them are still young. Sure it is a lot of fun. However, more often than I like (yet not terribly often since I have really good kids), I get caught in the middle of a “he said/no I didn’t” dispute. That is where one of my children shows up in a huff to wherever I am and reports what “he said”, he meaning another one of my children. Then in the background I’ll hear the other one say either the “no I didn’t’ or the “but that’s because he said” response. And both kids look at me and expect the impartial judge (a.k.a. me) to do something. Each of them will give the impression of complete honesty and full recollection, yet they cannot agree about what happened or about what the other said.

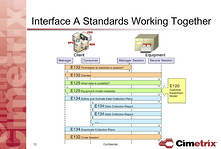

I have a lot of children—seven. Many of them are still young. Sure it is a lot of fun. However, more often than I like (yet not terribly often since I have really good kids), I get caught in the middle of a “he said/no I didn’t” dispute. That is where one of my children shows up in a huff to wherever I am and reports what “he said”, he meaning another one of my children. Then in the background I’ll hear the other one say either the “no I didn’t’ or the “but that’s because he said” response. And both kids look at me and expect the impartial judge (a.k.a. me) to do something. Each of them will give the impression of complete honesty and full recollection, yet they cannot agree about what happened or about what the other said. Industry organizations, such as SEMI and ISMI, have been touting the benefits of the Interface A, also known as EDA, standards for years. This year, SEMI approved an important revision to these standards to incorporate many of the lessons learned from early implementations. In addition, SEMATECH member companies (which make up 50 percent of the worldwide chip market) wanted ISMI to focus on a smaller number of projects with short-term benefits for 2009. Interface A (EDA) is on this short list.

Industry organizations, such as SEMI and ISMI, have been touting the benefits of the Interface A, also known as EDA, standards for years. This year, SEMI approved an important revision to these standards to incorporate many of the lessons learned from early implementations. In addition, SEMATECH member companies (which make up 50 percent of the worldwide chip market) wanted ISMI to focus on a smaller number of projects with short-term benefits for 2009. Interface A (EDA) is on this short list. As the Accounts Receivable Coordinator, people are not typically excited to hear from me. I’m a really nice guy and all… but usually, if you receive a call from me it’s about a past due invoice. And who likes receiving those calls?

As the Accounts Receivable Coordinator, people are not typically excited to hear from me. I’m a really nice guy and all… but usually, if you receive a call from me it’s about a past due invoice. And who likes receiving those calls? Today, Cimetrix held its 2nd annual soup cook-off. With the our first big storm of the season right around the corner, a good bowl of soup seems very fitting for this time of year.

Today, Cimetrix held its 2nd annual soup cook-off. With the our first big storm of the season right around the corner, a good bowl of soup seems very fitting for this time of year. Running a company during an industry downturn presents quite a challenge. I have always thought I would someday be the president of a company. However, during this severe semiconductor down cycle, the thought that you should “be careful what you wish for” certainly came to mind a few times. Even though Cimetrix is a small company, successfully navigating a business through a severe downturn that hit the semiconductor industry requires a combination of critical thinking, tough decisions and a durable stomach.

Running a company during an industry downturn presents quite a challenge. I have always thought I would someday be the president of a company. However, during this severe semiconductor down cycle, the thought that you should “be careful what you wish for” certainly came to mind a few times. Even though Cimetrix is a small company, successfully navigating a business through a severe downturn that hit the semiconductor industry requires a combination of critical thinking, tough decisions and a durable stomach. I’d like to draw your attention to two recent articles by

I’d like to draw your attention to two recent articles by