By David Francis

Product Manager

ISMI held a very successful EDA/Interface A workshop at SEMICON West in July, and Cimetrix was a guest speaker at the workshop. The attendance and interest in EDA was surprising, given that EDA has been discussed for five years with very little adoption to-date. Now, however, we see a major change occurring.

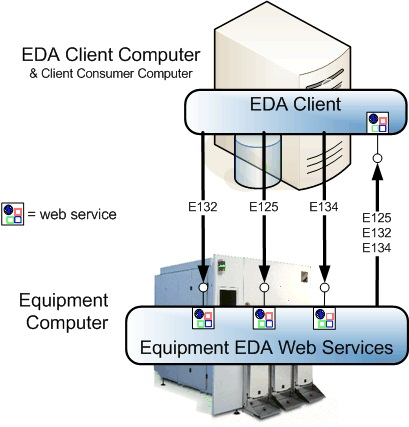

In November 2005, ISMI established the first freeze version of the Equipment Data Acquisition (EDA) Standards to enhance adoption by eliminating the “moving target” issue; it was known as the 1105 Freeze Version. The industry had good reasons for developing EDA. Fabs could get significantly higher trace data collection throughput, and the robust tool model in EDA provided better access to sensors and other key equipment variables useful for operational data monitoring. Moreover, EDA greatly simplified the creation of data collection plans (DCP), so fab engineers could resolve manufacturing problems faster and easier. Best of all, it decoupled data collection from SECS/GEM, so data collection would not be influenced by tool control nor would tool control performance be impacted by collection of large quantities of data. The result would be that fabs would benefit from more sophisticated automatic process control (APC) algorithms, improved yields, and reduced downtime.

Unfortunately, only a few brave equipment suppliers started work on developing interfaces for their equipment to comply with the 1105 Freeze Version. Not surprisingly, the general adoption and excitement in the industry around EDA didn’t last long in the absence of strong support from semiconductor manufacturers and foundry customers.

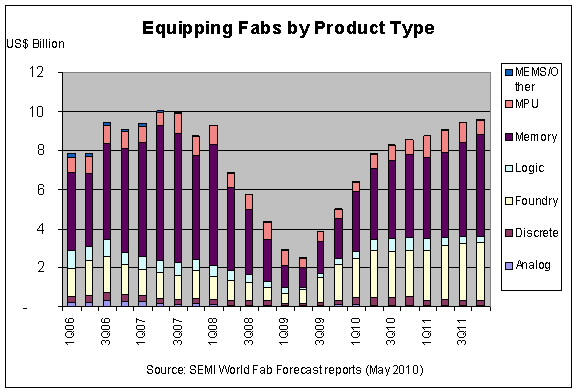

Why? It generally takes a significant amount of time for equipment suppliers and semiconductor manufacturers to review the standards and introduce new systems to deliver and consume the data. In the case of EDA this was further compounded because of bad timing in the industry. The 1105 freeze version of EDA came out during a boom time for the semiconductor industry, when fabs want to avoid making significant changes that could disrupt production. By the time the equipment vendors could develop new systems with an EDA interface, the industry experienced the biggest – and fastest – downturn in history. In 2008-2009, semiconductor companies were buying very few new machines, let alone starting new fabs.

But, when business in the industry turned back up in 2010, both GLOBALFOUNDRIES and Toshiba announced they would build new 300mm fabs, and would require OEMs to supply new equipment with an EDA interface. In addition, there are other semiconductor manufacturers and foundries who are investigating and starting to use EDA, but have not been as vocal about adopting the standard.

GLOBALFOUNDRIES Fab 1 in Dresden, Germany

Also in 2010, ISMI announced the second freeze version (the 0710 Freeze Version) of the EDA Standards. Since that announcement, there has been a lot of interest and activity in the industry surrounding Interface A. One reason, obviously, is that the two large semiconductor manufacturers have added Interface A to their equipment purchase specifications and acceptance criteria, so equipment suppliers want to ensure that their products comply with these new requirements.

But there are other reasons for interest in EDA. The 0710 freeze version provides a number of simplifications and clarifications of the 1105 freeze version. For example, there is better linkage between the SECS/GEM events and variables and the EDA constructs, and the metadata is simpler. There have also been other changes, like using simple events as an alternative to complete state machines, and allowing DCP behavior to be separate for each client. As the industry tackles 3D designs with ever smaller geometries, the process window gets a lot narrower and access to data and applications to consume this data become imperatives instead of “nice-to-haves.”

In addition, ISMI has updated its EDA Guidance document to more fully describe how to implement EDA interfaces. In parallel, ISMI partnered with Cimetrix to develop the new version of the Equipment Client Connection Emulator (ECCE) that OEMs and semiconductor manufacturers can use to verify EDA interfaces (see New Freeze Version of Interface A Requires New ECCE Version). Finally, the ISMI/NIST Metadata Conformance Analyzer (MCA) is also available to check for conformance of equipment metadata to the applicable portions of the SEMI standards and ISMI guidelines.

It is exciting to see the renewed interest and attention to EDA. Is all the attention because semiconductor manufacturers are starting to require EDA, or are semiconductor manufacturers starting to require it because of all the recent interest? Either way, there are genuine opportunities for both equipment suppliers and semiconductor manufacturers to make use of data collected through EDA to improve efficiencies and open new capabilities for microelectronics manufacturing.