By David Francis

Product Manager

I ran across an old issue of Future Fab International – Issue 6 – that I have had since it was published in 1998. I helped write an article that was published in this issue titled “Complete System Integration is Crucial to the Success of 300mm Manufacturing.” The article looked at changes that would be required in semiconductor manufacturing to support the move from 200mm wafers to 300mm wafers.

At the time, I was working for a software company that specialized in the development of Material Control Systems (MCS) for controlling Automated Material Handling Systems (AMHS). Most of the 200mm manufacturing facilities had implemented inter-bay transport systems that move material from one manufacturing bay to another, but within the bays, operators manually loaded wafers onto process or metrology equipment. Operators had to decide what work should be done next, or where the material should go after each process, after reviewing choices from a dispatch screen. There were islands of automation, but not much integration.

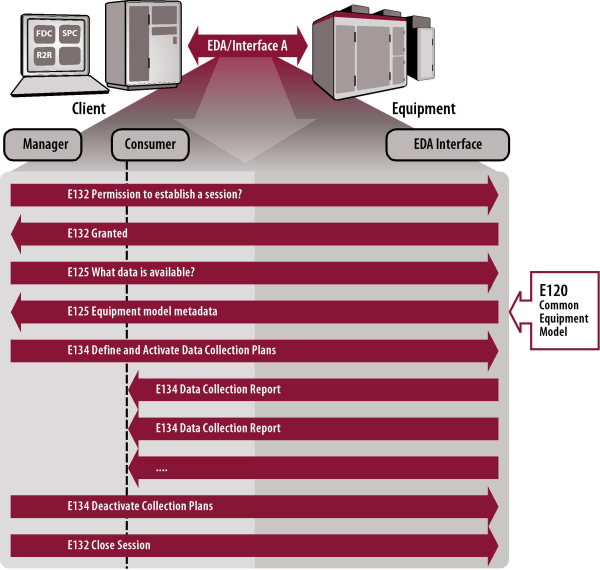

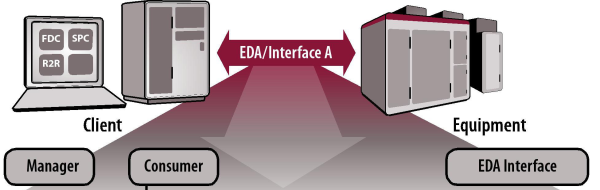

With the size, weight, and bulk of the 300mm carriers, transport systems would need to deliver material directly to the processing or metrology tool. This required very tight integration between the MCS, the dispatching system, and the factory Manufacturing Execution System (MES). In 1998 the GEM300 standards that would make all this possible had not been adopted very widely yet and were only starting to get semiconductor equipment suppliers’ attention.

This old article talked about the need for developing a reliable, low-footprint intra-bay transport system. It also explored the new concept of having the dispatch system make the decision about what work to do next rather than just suggesting what could be done. The MCS would need to interface with the dispatching system to be able to position material close to where it would be needed for processing.

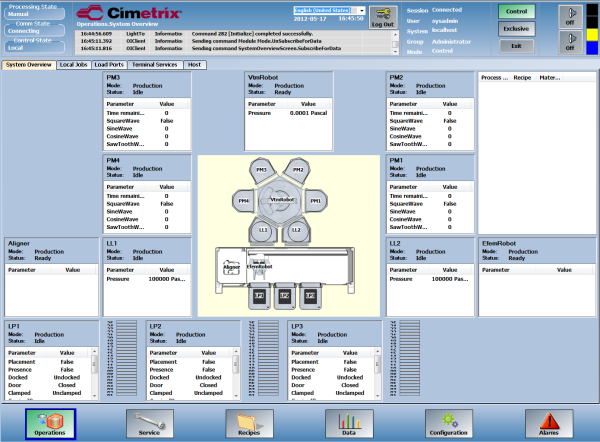

The SEMI GEM 300 standards started gaining traction about the year 2000 and the idea of “lights out” manufacturing soon became a reality. It has been exciting to watch as the MES, dispatcher, AMHS and MCS systems have progressed and the fully automated, integrated manufacturing environment described in the article has become a reality.

While the move to 450mm wafers is probably still a few years off, I expect that transition will be much easier than the transition from 200mm to 300mm because of the work done for 300mm factories. The standards are well established, the control systems have matured, and the integration of the various components is very stable. It is exciting to see these future visions become common practice.

Recently, Cimetrix updated our Introduction to SEMI GEM 300 Standards white paper. We have refreshed the content to answer some of the questions many people pose to us. Take a look and let us know what you think.