As the SEMI GEM standard celebrates its 25th birthday, you may have thought its evolution had just about run its course — but you’d be wrong. Last year, the Information and Control Committee of SEMI Standards passed two new standards that enhance the usability of the entire SECS/GEM suite of standards for equipment suppliers and semiconductor manufacturers alike: E172 SEDD and E173 SMN.

Let us talk about the first of these, the E172 Specification for the SECS Equipment Data Dictionary (SEDD) and postpone E173 Specification for XML SECS-II Message Notation (SMN) discussion for another blog. SEDD standardizes the approach for documenting an equipment’s GEM interface in a way that is both human- and computer-readable. All factories in every industry that use GEM require their equipment suppliers to provide GEM interface documentation in some electronic form for each type of equipment. This is because the GEM interface on every equipment type is unique, supporting unique features and publishing a unique set of data. Of course, the GEM standard itself requires documentation and what has to be in the documentation but does not specify how this is to be accomplished. Until now there has been no common approach or format. This has always left the equipment suppliers to come up with their own format. At best this might be in a multiple-tabbed Excel spreadsheet or a PDF file; and at worst a text document that might or might not have been accurate or even complete. And every equipment supplier completes the documentation in a different structure and style so that no two GEM documents look the same. In summary, everyone is trying to complete this GEM and factory requirement by providing documentation, but in the end what factories are receiving has to be consumed and digested differently based on the equipment supplier, and sometimes even based on the specific equipment type from the same equipment supplier. It is a lot of work for the factory just to understand exactly what is in each GEM interface.

SEDD was created to solve this problem by defining a standard XML schema for documenting a GEM interface. Equipment suppliers create an XML file that complies with the SEDD XML schema to document the GEM interface and then deliver this XML file (called an SEDD file) to the factory.

Why XML? Because XML is the perfect technology for organizing data into a uniform structure that is well supported by modern programming languages. This means that equipment suppliers can use a software program to generate the SEDD file. It also means that factories can write software to read and view the SEDD file. Moreover, they can create intelligent host applications that automatically configure themselves and adapt to a specific GEM interface.

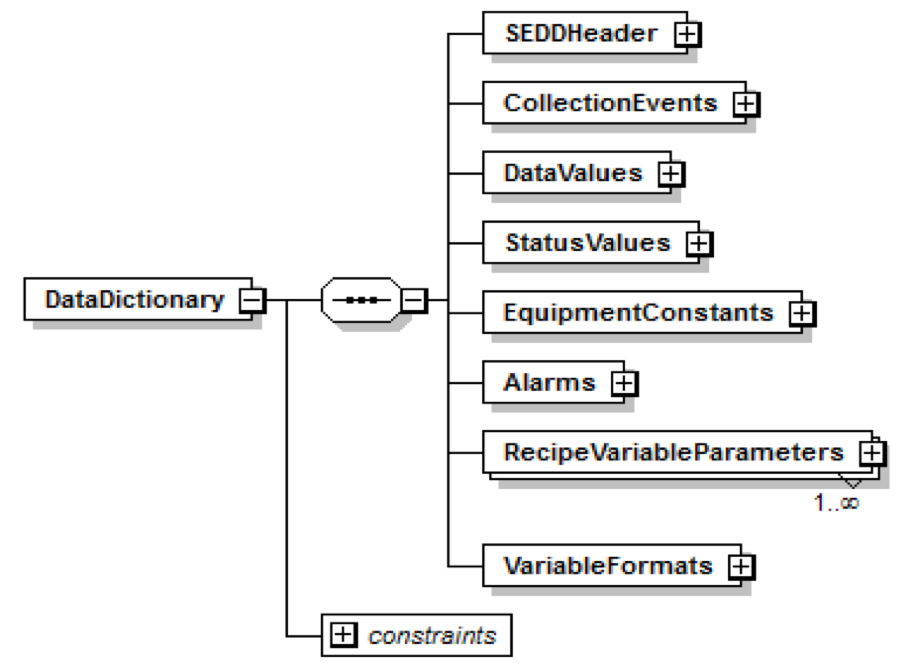

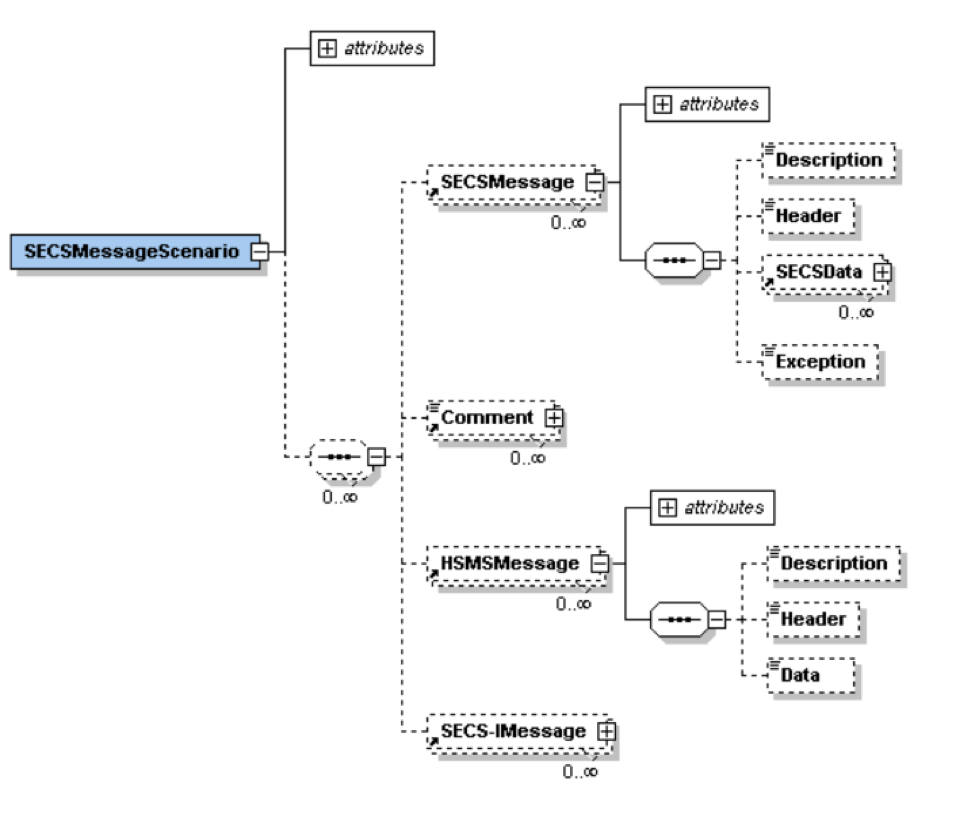

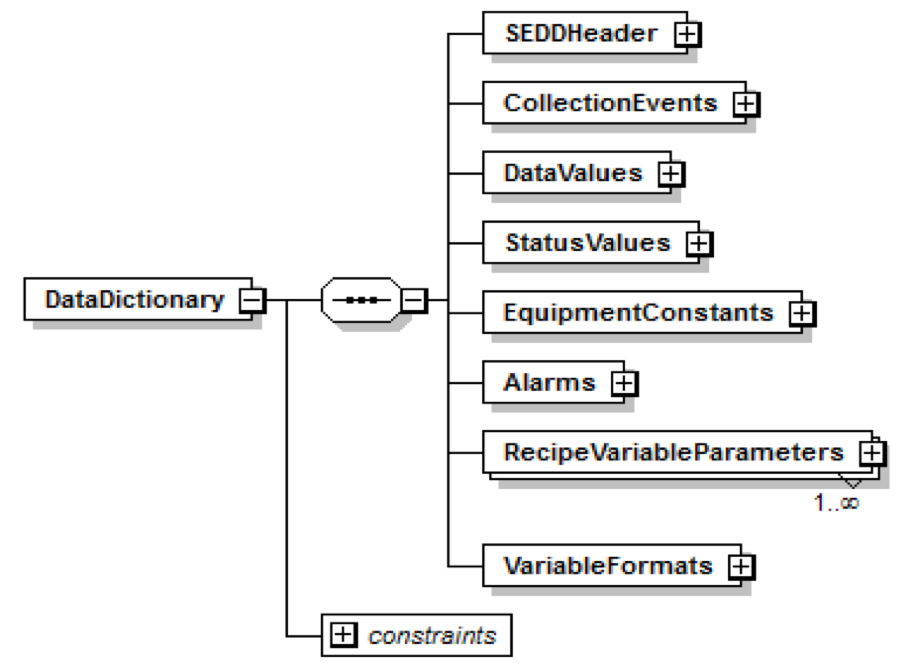

So what’s in an SEDD file? Below is a visual representation of the SEDD file schema, identifying the major elements of the SEDD file.

So essentially the SEDD file includes a list of the data available for collection by a host, some general information about the equipment (in the header), and the format of the data variables, status variables and equipment constants. As an example of what details are included, here are the details for collection events.

So essentially the SEDD file includes a list of the data available for collection by a host, some general information about the equipment (in the header), and the format of the data variables, status variables and equipment constants. As an example of what details are included, here are the details for collection events.

As an example, for a collection event, the SEDD file includes a list of all collection events available, and the ID, name, description, related SEMI standard, and the list of related data variables and other variables for that collection event. This is everything you need to use a collection event.

So far this is a summary of what is available today in a SEDD file. Cimetrix is leading the GEM300 task to extend the SEDD file to include additional information. This work is in SEMI ballot 5872 that proposes to extend the SEDD file to also include:

-

A list of supported SECS-II messages and the acceptable format for each message (using E172 SMN)

-

A list of support remote commands and available parameters for each remote command

-

A list compliance tables for supported SEMI standards

-

The list of predefined event reports

This is all work that was postponed from the original SEDD standard development. Hopefully ballot 5872 will pass and make SEDD files even more useful. With this additional information an SEDD file would empower GEM host software to configure itself to fully communicate with a GEM interface and make all of the features in the GEM interface available.

This is one example of how GEM technology just keeps getting better. It is not surprising that GEM is getting used in more and more industries.

For more information about this latest standard, and how you can incorporate it into your interface implementation, please contact us.♦

We highlighted our CIMPortal Plus software demonstrating the benefits of the SEMI E164 standard. Attendance seemed light this year which allowed the Cimetrix team ample time to meet with various equipment supplier customers who had exhibits at the show. Of particular interest to our customers was our advice on when and how to add Interface A to their control systems, and what impact Industry 4.0 and smart manufacturing will bring. The evening networking event was very well done; congrats to the SEMI team.

We highlighted our CIMPortal Plus software demonstrating the benefits of the SEMI E164 standard. Attendance seemed light this year which allowed the Cimetrix team ample time to meet with various equipment supplier customers who had exhibits at the show. Of particular interest to our customers was our advice on when and how to add Interface A to their control systems, and what impact Industry 4.0 and smart manufacturing will bring. The evening networking event was very well done; congrats to the SEMI team.

In a previous blog we mentioned that two new SEMI standards, E172 and E173, demonstrated that the GEM standard was alive and well and even gaining new momentum by evolving to adopt new technology. The earlier blog focused on E172 with its SEDD files that use an XML schema to describe what is in a GEM interface. Today’s blog is about the E173 Specification for XML SECS-II Message Notation: a new way to log and document GEM/SECS messages, again using an XML schema.

In a previous blog we mentioned that two new SEMI standards, E172 and E173, demonstrated that the GEM standard was alive and well and even gaining new momentum by evolving to adopt new technology. The earlier blog focused on E172 with its SEDD files that use an XML schema to describe what is in a GEM interface. Today’s blog is about the E173 Specification for XML SECS-II Message Notation: a new way to log and document GEM/SECS messages, again using an XML schema.

So essentially the SEDD file includes a list of the data available for collection by a host, some general information about the equipment (in the header), and the format of the data variables, status variables and equipment constants. As an example of what details are included, here are the details for collection events.

So essentially the SEDD file includes a list of the data available for collection by a host, some general information about the equipment (in the header), and the format of the data variables, status variables and equipment constants. As an example of what details are included, here are the details for collection events.