Yufeng Huang of Cimetrix China, talks about Equipment Control in the factory. Read now in Chinese or below in English.

在和半导体设备制造公司的接触中我们遇到这么一个尴尬的问题,很多懂得设备控制的优秀软件工程师对于GEM,GEM300和EDA标准不是很有经验。这些公司往往是在设备在实验室研发成功,准备产业化送入客户工厂时发现设备没有实现或只有部分实现GEM/GEM300标准,尤其是当客户工厂要求EDA(Interface A)通信接口的时候,这些设备制造商的软件工程师往往一脸茫然,不知道如何在短时间内开发出完全遵循GEM/GEM300/EDA标准的软件。

对于大多数设备公司而言,限制于有限的人力、财力资源,公司很难聘请到足够多富有经验的工厂自动化软件工程师开发自己的GEM/GEM300,甚至EDA软件模块。另外一个棘手的问题是我们发现很多软件工程师不是特别有意愿加入到半导体行业,而是选择比较热门的互联网、游戏,手机App等软件行业。纵观半导体工厂自动化软件市场,虽然已有多家公司提供GEM/GEM300/EDA的软件开发包(SDK),但软件工程师仍旧需要掌握一定的工厂自动化基础知识才能着手编写软件集成代码。工厂自动化涉及大量SEMI标准,譬如GEM标准大概有450页文档,包括E4,

E5,

E30,

E37,E37.1,E172,E173,GEM300标准大概有280页文档,包括E39,E40,E87,E90,E94,E116,E157,E148,而更为复杂的EDA标准大概480有页文档,包括E120,E125,E128,E132,E134,E138,E164,对于大多数非专业的工厂自动化软件工程师而言,工厂自动化软件的集成工作是一件极其繁琐而艰难的任务。

Cimetrix Control FrameworkTM (CCF) 是基于微软.Net技术的设备自动化控制软件框架,该软件不仅为设备制造厂商提供了监督控制和生产控制框架代码,而且完全实现了GEM/GEM300/EDA标准。借助CCF软件平台,软件工程师无需深刻掌握工厂自动化的所有SEMI标准,就能轻松变身为工厂自动化开发专家。CCF软件框架内的工厂自动化模块基于Cimetrix公司的CIMConnect,CIM300,CIMPortal Plus三个独立的软件开发套件(SDK)实现,分别对于实现GEM,GEM300,和EDA标准。全球任意一家300mm的芯片制造工厂都有安装了CIM300软件的设备运行,在支持EDA数据采集的工厂都有安装了CIMPortal Plus软件的设备运行。CCF软件框架将所有工厂自动化的开发工作交给Cimetrix公司来完成,设备软件工程师可以把更多的时间花费在如何设计自己的设备控制软件上。

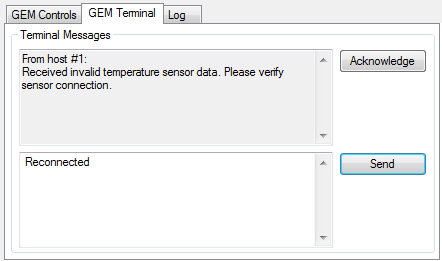

在CCF框架下,CIMConnect/CIM300/CIMPortal Plus的底层API函数都被很好作了封装,软件工程师只需通过CCF框架提供的函数或接口就能轻松实现和工厂主机程序的所有GEM/GEM300标准。实现EDA标准的一个重要任务是创建一个支持分层次结构的设备模型,以及按照标准生成XML数据,此外生成的模型还需满足E164标准。在CCF软件初始化运行时会动态生成设备模型,软件工程师几乎不需要书写EDA代码,设备即可很好的遵循EDA标准。

采用CCF软件框架降低设备控制程序和工厂自动化程序的开发难度和开发周期,但并不意味着我们的客户一定得推翻自己已有的软件平台或已经测试过的稳定代码。CCF是一个提供源代码的完全开放的自动化控制程序框架,你可以将CCF理解成一个已经拼好的乐高玩具,用户既可以将自己的代码模块集成到CCF中,也可以挑选部分CCF功能模块并将其转移到用户自己的框架中。我们用户将CCF中工厂自动化模块(包括GEM/GEM300/EDA)搬迁到自己的程序框架中,在保证完全遵循工厂自动化诸多SEMI标准的同时,对用户已有程序的影响非常小。

得益于CCF框架的完全开放性,像玩乐高积木一样,软件工程师可以轻松享受自由裁剪自己想要的控制系统框架带来的乐趣,这是其他任何一家提供设备控制软件框架程序的公司都很难做到的一件事情。

在未来几年,越来越多的工厂往智能生产制造的方向发展,由此对数据的需要越来越高,EDA标准越来越成为工厂主流的数据采集方法,CCF无疑成为了设备制造商更快更好实现各种工厂自动化标准的最佳武器。

We encountered an interesting issue when working with semiconductor equipment manufacturing companies. Many excellent software engineers who know equipment control are not very experienced with the GEM, GEM300, and EDA standards. Sometimes after equipment is successfully developed in the laboratory and before the equipment is shipped to the factory, we discover that the equipment did not implement or only partially implemented the required GEM/GEM300/EDA standard. This is especially prevalent when the factory requires the EDA (Interface A) communication interface. Equipment software engineers sometimes do not know how to develop software that fully complies with GEM/GEM300/EDA standards in a short period of time.

For most equipment companies with limited human and financial resources, it is difficult for the company to have the resources to develop their own GEM/GEM300/EDA software. Another issue is that we have found many of the more experienced software engineers are more interested in high-profile internet, gaming, mobile phone apps and other software industries rather than the lower profile semiconductor industry. Although many companies in the semiconductor factory automation software market have provided GEM/GEM300/EDA software development kits (SDKs), software engineers still need to master certain basic knowledge of factory automation to start writing software integration code. Factory automation involves a large number of SEMI standards. For example, the GEM standard has about 450 pages of documents, including E4, E5, E30, E37, E37.1, E172, E173. GEM300 standards have about 280 pages of documents, including E39, E40, E87, E90, E94, E116, E157, E148. The more complex EDA standard has about 480 pages, including E120, E125, E128, E132, E134, E138, E164. For less experienced factory automation software engineers, the integration of automation software can be an extremely tedious and difficult task.

Cimetrix CIMControlFrameworkTM (CCF) is an equipment automation control software framework based on Microsoft .Net technology. This software not only provides equipment manufacturers with supervisory control and equipment control framework code, but also fully implements the GEM, GEM300 and EDA standards. With the help of the CCF software platform, software engineers can easily turn into factory automation development experts without having to master all the factory automation SEMI standards. The factory automation components within the framework of the CCF software are based on CIMConnect, CIM300, and CIMPortal Plus, three independent software development kits (SDKs) from Cimetrix for the implementation of the GEM, GEM300, and EDA standards, respectively. All 300mm chip manufacturing factories in the world have equipment installed which uses CIM300 software. Any factory requiring EDA data collection has equipment installed that uses CIMPortal Plus software. With the CCF software framework, Cimetrix has already done the work of integrating all factory automation into the framework. The equipment software engineer can spend more time on how to develop their own equipment control software.

Under the CCF framework, the underlying API functions of CIMConnect/CIM300/CIMPortal Plus are well encapsulated. Software engineers can easily implement all the GEM/GEM300/EDA standards of the factory host program through the functions or interfaces provided by the CCF framework. An important task in implementing the EDA standard is to create an equipment model that supports hierarchical structures and generate XML data in accordance with standards. In addition, the generated model must also meet the SEMI E164 standard. The equipment model is dynamically generated when the CCF software is initialized. The software engineer needs to do very little to have an equipment control application that is fully compliant with the EDA standard.

The use of the CCF software framework to reduce the difficulty and development cycle of equipment control programs and factory automation programs does not mean that our clients must replace their existing software platforms or stable code that has been tested. CCF is a fully open automation control program framework that provides source code. You can think of CCF as a LEGO toy that has been put together. Users can either integrate their own code modules into CCF or select some of the CCF functional modules and transfer them to their own framework. Our clients can reuse the factory automation modules (including GEM/GEM300/EDA) in CCF in their own program frameworks. While ensuring that all SEMI standards for factory automation are fully complied with. The impact on the user's existing programs is minimal.

Thanks to the complete openness of the CCF framework, like LEGO bricks, software engineers can easily enjoy the freedom of tailoring the control system framework that they want. It is hard for any company that provides an equipment control software framework program to implement such a rich library of functions.

In the next few years, more and more factories will move in the direction of smart manufacturing. As a result, the demand for data is getting higher and higher. EDA standards are increasingly becoming the factory's mainstream data collection method. CCF will undoubtedly become the best weapon for equipment manufacturers to quickly and completely implement the various factory automation standards.

The Quality Software Engineering team at Cimetrix is dedicated to delivering the highest quality software products to all Cimetrix customers. The QE team works closely with the development engineers to plan and build sound, testable solutions in an agile working environment. Through rigorous testing and creative problem solving, we advocate for and build quality into our products. We accomplish this with a determined team that works hard to uphold high standards of both software functionality, and software structure.

The Quality Software Engineering team at Cimetrix is dedicated to delivering the highest quality software products to all Cimetrix customers. The QE team works closely with the development engineers to plan and build sound, testable solutions in an agile working environment. Through rigorous testing and creative problem solving, we advocate for and build quality into our products. We accomplish this with a determined team that works hard to uphold high standards of both software functionality, and software structure.

Cimetrix participated in the recent European Advanced Process Control and Manufacturing (apc|m) Conference, along with over 160 control systems professionals across the European and global semiconductor manufacturing industry. The conference was held in Dresden, a beautiful city in the Saxony state of Germany which was the site of the original European conference in 2000 and host to this annual event many times since.

Cimetrix participated in the recent European Advanced Process Control and Manufacturing (apc|m) Conference, along with over 160 control systems professionals across the European and global semiconductor manufacturing industry. The conference was held in Dresden, a beautiful city in the Saxony state of Germany which was the site of the original European conference in 2000 and host to this annual event many times since.

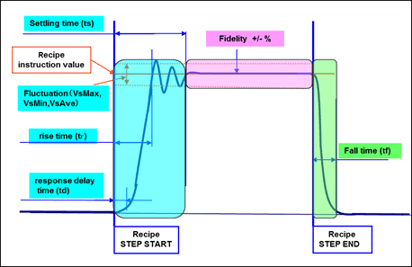

“FDC to the power of 2 – how it got us to the next level of manufacturing excellence“ by Jan Räbiger of GLOBALFOUNDRIES – one of a number of long-time thought leaders in the development and application of APC technology, Jan described the latest phase of FDC system evolution, which includes broad use of the EDA/Interface A standards to zero in on recipe step-specific anomalies that had previously escaped detection.

“FDC to the power of 2 – how it got us to the next level of manufacturing excellence“ by Jan Räbiger of GLOBALFOUNDRIES – one of a number of long-time thought leaders in the development and application of APC technology, Jan described the latest phase of FDC system evolution, which includes broad use of the EDA/Interface A standards to zero in on recipe step-specific anomalies that had previously escaped detection.

Meet Jesse Lopez, a member of the Solutions Engineering team. Read on to learn a little bit more about Jesse.

Meet Jesse Lopez, a member of the Solutions Engineering team. Read on to learn a little bit more about Jesse. I remember as a new Boy Scout, we planned a hiking trip up into a primitive area in the mountains near my home. One of the first things we learned about reading a map was where to find the legend. The map legend contains important information needed to read a map, like indicating which direction is north. Now that we knew where to find the legend, we could orient the map so it made sense as we were planning our hike.

I remember as a new Boy Scout, we planned a hiking trip up into a primitive area in the mountains near my home. One of the first things we learned about reading a map was where to find the legend. The map legend contains important information needed to read a map, like indicating which direction is north. Now that we knew where to find the legend, we could orient the map so it made sense as we were planning our hike. Meet Ian Ryu, a member of the Solutions Engineering team in Korea. Read on to learn a little bit more about Ian.

Meet Ian Ryu, a member of the Solutions Engineering team in Korea. Read on to learn a little bit more about Ian.

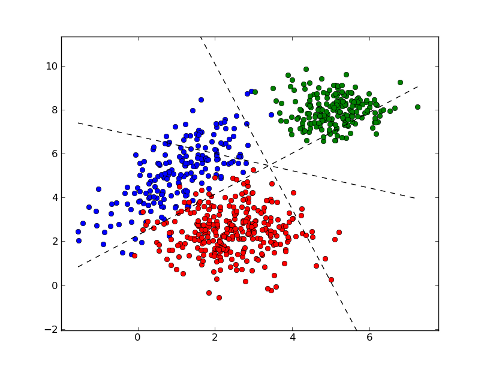

The other major solution component for a production FDC system is a fault model library management capability that can handle large numbers of models. This is necessary because the multivariate approach includes little or no awareness of the physical meaning of the principal components (i.e., they are not “first principles” based), so different operating points for the equipment must have their own sets of fault models. The proper models for a given operating point are selected by matching the values of the “context parameters” for a specific run to those used to store the models. Even if some models can be shared across a range of operating points, the number of distinct models for a foundry megafab will still number in the thousands.

The other major solution component for a production FDC system is a fault model library management capability that can handle large numbers of models. This is necessary because the multivariate approach includes little or no awareness of the physical meaning of the principal components (i.e., they are not “first principles” based), so different operating points for the equipment must have their own sets of fault models. The proper models for a given operating point are selected by matching the values of the “context parameters” for a specific run to those used to store the models. Even if some models can be shared across a range of operating points, the number of distinct models for a foundry megafab will still number in the thousands.

Meet Mark Bennett, a member of the Solutions Engineering team. Read on to learn a little bit more about Mark.

Meet Mark Bennett, a member of the Solutions Engineering team. Read on to learn a little bit more about Mark.