It’s amazing enough to think that a single factory can start 100,000 wafers every month on their cyclical journey through 1500 process steps… and have 99%+ of them emerge 4 months later to be delivered to packaging houses and then on to waiting customers. It’s quite another to realize that all of this happens continuously (24 x 7) and automatically.

“How is this possible?” you ask.

Well, a big part of the solution is the body of SEMI standards which have evolved since the early 80s to keep pace with the ever-changing demands of the industry. From an automation standpoint, many of these standards deal with the communications between manufacturing equipment and the factory information and control systems that are essential for managing these complex, hyper-competitive global enterprises.

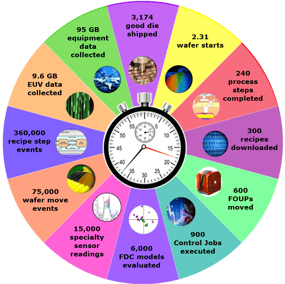

A significant characteristic of these standards is that they have been carefully designed to be “additive.” This means that new generations of SEMI’s communications standards do not supplant or obsolete the previous generations, but rather provide new capabilities in an incremental fashion. To appreciate the importance of this in actual practice, consider how the GEM, GEM300, and EDA/Interface A standards support the transactions that occur in a single Gigafab Minute.

Starting at 1:00 o’clock on the infographic and moving clockwise, you first notice that 2.31 wafers enter the line. Of course, these are actually released in 25-wafer 300mm FOUPs (Front-Opening Unified Pod), but 100K wafers per month translates to 2.31 per minute. Since these factories run continuously, once the line is full, it stays full. And with an average total cycle time of 4 months, this means that there are 400K wafers of WIP (work in process) in the factory at any given time. This number, and the total number of equipment (5000+), drive the rest of the calculations.

GEM (Generic Equipment Model) – SEMI E30, etc.

The GEM messaging standards were initially defined in the early 90s to support the factory scheduling and dispatching applications that decide what lots should go to what equipment, the automated material handling systems that deliver and pick-up material to/from the equipment accordingly, the recipe management systems that ensure each process step is executed properly, and the MES (Manufacturing Execution System) transactions that maintain the fidelity of the factory system’s “digital twin.”

Every minute of every day, GEM messages support and chronicle the following activities: 240 process steps are completed (i.e., 240 25-wafer lots are processed), 300 recipes are downloaded along with a set of run-specific adjustable control parameters, and 600 FOUPs are moved from one place to another (equipment, stockers, under-track storage, etc.). For each of these activities, the factory’s MES is notified instantaneously.

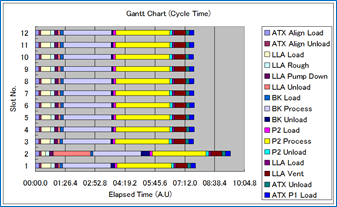

GEM300 – SEMI E40, E87, E90, E94, E157

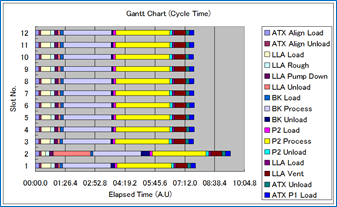

With the advent of 300mm manufacturing in the mid-to-late 90s, a global team of volunteer system engineers from the leading chip makers defined the GEM300 standards to support fully automated manufacturing operations. Starting at 5:00 o’clock on the infographic, the number of transactions per minute jumps almost 3 orders of magnitude, from the monitoring of 900 control jobs across 4000 process tools to the tracking of 360,000 individual recipe step change events. This level of event granularity is essential for the latest generation of FDC (Fault Detection and Classification) applications, because precise data framing is a key prerequisite for minimizing the false alarm rate while still preventing serious process excursions. In this context, more than 6000 recipe-, product- and chamber-specific fault models may be evaluated every minute.

Simultaneously, the applications that monitor instantaneous throughput to prevent “productivity excursions” and identify systemic “wait time waste” situations depend on detailed intra-tool wafer movement events. In a fab with hundreds of multi-chamber, single-wafer processes, 75,000 or more of these events occur every minute.

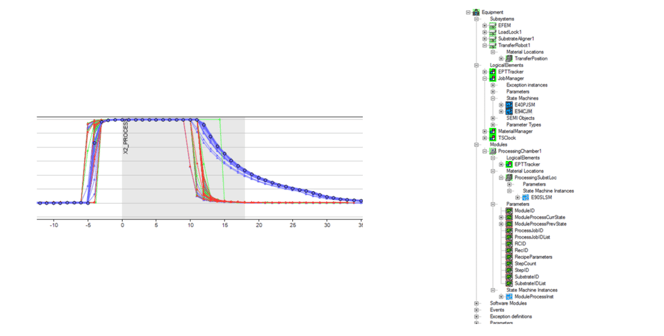

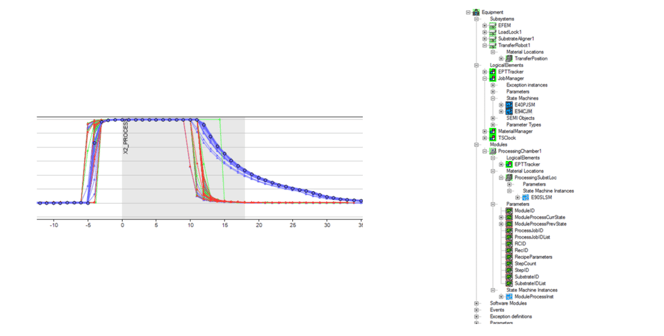

EDA (Equipment Data Acquisition) – SEMI E120, E125, E132, E134, E164, etc.

Rounding out the SEMI standards in our example gigafab is the suite of EDA standards which complement the command and control functions of GEM/GEM300 with flexible, high-performance, model-based data collection. The EDA standards enable the on-demand collection of the volume and variety of “big data” required from the equipment to support the advanced analysis, machine learning, and other AI (Artificial Intelligence) applications that are becoming increasingly prevalent in leading semiconductor manufacturers. As EUV (Extreme Ultraviolet) lithography moves from pilot production to high-volume manufacturing at the 7nm process node and beyond, the litho process area will become a major source of process data by itself, generating 10 GB of data every minute. This is in addition to the 100 GB of data collected from other process areas.

The End Result

The final wedge (12:00 o’clock) in our infographic highlights the real objective – which is producing the millions of integrated circuits that fuel our global economy and provide the technologies that are an integral part of our modern way of life. Assuming a nominal die size of 50 square mm (typical of an 8 GB DRAM), the 2.31 wafers we started at 1:00 o’clock result in almost 3200 individual chips. But none of this would be possible without the pervasive factory automation technology we now take for granted. So, as you finish reading this posting on whatever device you happen to be using, take a micro-moment to acknowledge and thank the hundreds of standards volunteers whose insights and efforts made this a reality!

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

You can see this infographic and much more in the Cimetrix Resource center.

*The Gigafab Minute was inspired by an analogous explication of the scope and impact of today’s Internet from Lori Lewis and Chadd Callahan of Cumulus Media, and published on the Visual Capitalist web site (http://www.visualcapitalist.com/internet-minute-2018/)

シンメトリックスは、来週開催されるセミコンジャパン2018に向け、準備を進めています。今年も皆様にお会いできることを、楽しみにしております。Read now in Japanese or below in English.

シンメトリックスは、来週開催されるセミコンジャパン2018に向け、準備を進めています。今年も皆様にお会いできることを、楽しみにしております。Read now in Japanese or below in English. Cimetrix is gearing up for the 2018 SEMICON Japan show next week, and we hope to see many of you there! This year we will have a booth in the Smart Manufacturing Area (#3493) and we will also be co-exhibiting with Rorze (#5507) and Meiden (#4626) who have been our long-time distributors. We look forward to meeting with clients, prospects and colleagues to discuss new opportunities.

Cimetrix is gearing up for the 2018 SEMICON Japan show next week, and we hope to see many of you there! This year we will have a booth in the Smart Manufacturing Area (#3493) and we will also be co-exhibiting with Rorze (#5507) and Meiden (#4626) who have been our long-time distributors. We look forward to meeting with clients, prospects and colleagues to discuss new opportunities.

简单地实现EDA接口功能和正确有效地实现的结果是不一样的。我从中得到的教训之一是,我们花了几乎整整一年的时间来实现EDA Freeze I的各种功能,并为测试的需要开发了客户端软件。然而,当我们将我们的EDA解决方案发布给客户工厂时,他们使用权威的第三方测试软件产品对所有设备的EDA解决方案进行了验证。我们的实现最初没有通过验收,因为我们对EDA标准的理解与客户的理解有些差异。为此我们花了很长时间来逐一解决验收中遇到的问题。商业的EDA解决方案通常已经在许多工厂得到了验证,因此更加标准化。

简单地实现EDA接口功能和正确有效地实现的结果是不一样的。我从中得到的教训之一是,我们花了几乎整整一年的时间来实现EDA Freeze I的各种功能,并为测试的需要开发了客户端软件。然而,当我们将我们的EDA解决方案发布给客户工厂时,他们使用权威的第三方测试软件产品对所有设备的EDA解决方案进行了验证。我们的实现最初没有通过验收,因为我们对EDA标准的理解与客户的理解有些差异。为此我们花了很长时间来逐一解决验收中遇到的问题。商业的EDA解决方案通常已经在许多工厂得到了验证,因此更加标准化。 3. 时机

3. 时机

The focus of this blog posting is the decision that many semiconductor manufacturing equipment suppliers face when deciding how to address the automation requirements of their most advanced customers, namely, whether or not to buy a commercial software package that supports the SEMI Equipment Data Acquisition (EDA / Interface A) Standards, or to develop this capability in-house.

The focus of this blog posting is the decision that many semiconductor manufacturing equipment suppliers face when deciding how to address the automation requirements of their most advanced customers, namely, whether or not to buy a commercial software package that supports the SEMI Equipment Data Acquisition (EDA / Interface A) Standards, or to develop this capability in-house. Simply being able to implement the EDA interface functions is not the same as implementing them in a robust fashion. One of my lessons learned is that we spent almost an entire year to implement the EDA Freeze I version of the standards and the client software required to test these functions. However, when we released the EDA interface to the factory customer, they qualified the EDA solution for all equipment modules with an authoritative third-party compliance testing software product. Our implementation failed at first because our understanding of the SEMI Standards specifications was different from the customer’s understanding. So we struggled for a long time to fix all the problems. A commercial EDA package will necessarily have been proven in many sites and is therefore far more standardized.

Simply being able to implement the EDA interface functions is not the same as implementing them in a robust fashion. One of my lessons learned is that we spent almost an entire year to implement the EDA Freeze I version of the standards and the client software required to test these functions. However, when we released the EDA interface to the factory customer, they qualified the EDA solution for all equipment modules with an authoritative third-party compliance testing software product. Our implementation failed at first because our understanding of the SEMI Standards specifications was different from the customer’s understanding. So we struggled for a long time to fix all the problems. A commercial EDA package will necessarily have been proven in many sites and is therefore far more standardized. Meet Morgan Kap, one of our QE Software Engineers. Read on to learn a little bit more about Morgan.

Meet Morgan Kap, one of our QE Software Engineers. Read on to learn a little bit more about Morgan.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

You may not be responsible for running a gigafab anytime soon, but the SEMI standards used in this setting are no less applicable to any Smart Manufacturing environment. Give us a call if you’d like to know more about how these technologies can benefit your operations for many years to come.

Meet Bryce Ostler, one of our QE Software Engineers. Read on to learn a little bit more about Bryce.

Meet Bryce Ostler, one of our QE Software Engineers. Read on to learn a little bit more about Bryce. SEMICON Taiwan was held September 5-7, 2018 at the Taipei Nangang Exhibition Center. During that same time (Friday September 7), the e-Manufacturing & Design Collaboration Symposium (eMDC) alsotook place in Hsinchu, Taiwan. Cimetrix exhibited in the Smart Manufacturing Pavilion and had a strong presence at both shows, exhibiting and speaking at SEMICON, and speaking and sponsoring a tea break at eMDC.

SEMICON Taiwan was held September 5-7, 2018 at the Taipei Nangang Exhibition Center. During that same time (Friday September 7), the e-Manufacturing & Design Collaboration Symposium (eMDC) alsotook place in Hsinchu, Taiwan. Cimetrix exhibited in the Smart Manufacturing Pavilion and had a strong presence at both shows, exhibiting and speaking at SEMICON, and speaking and sponsoring a tea break at eMDC.  In addition to the exhibitions, SEMICON Taiwan also sponsored many forums for expert speakers throughout the show. Dave Faulkner spoke on Friday morning on the topic of "Making Smart Manufacturing Work with EDA: The Stakeholder-driven requirements Development Process". On that same day, Alan Weber traveled to Hsinchu for eMDC and spoke on a similar topic, "Smart Manufacturing Stakeholders and Their Requirements." Smart Manufacturing is a prevailing topic across the industry and was featured at SEMICON Taiwan, as they continue the Smart Manufacturing Journey that began with SEMICON West.

In addition to the exhibitions, SEMICON Taiwan also sponsored many forums for expert speakers throughout the show. Dave Faulkner spoke on Friday morning on the topic of "Making Smart Manufacturing Work with EDA: The Stakeholder-driven requirements Development Process". On that same day, Alan Weber traveled to Hsinchu for eMDC and spoke on a similar topic, "Smart Manufacturing Stakeholders and Their Requirements." Smart Manufacturing is a prevailing topic across the industry and was featured at SEMICON Taiwan, as they continue the Smart Manufacturing Journey that began with SEMICON West.  If you would like to learn more about Smart Manufacturing, our work in Taiwan or Cimetrix, please feel free to ask an expert any time.

If you would like to learn more about Smart Manufacturing, our work in Taiwan or Cimetrix, please feel free to ask an expert any time.