By David Francis

Product Manager

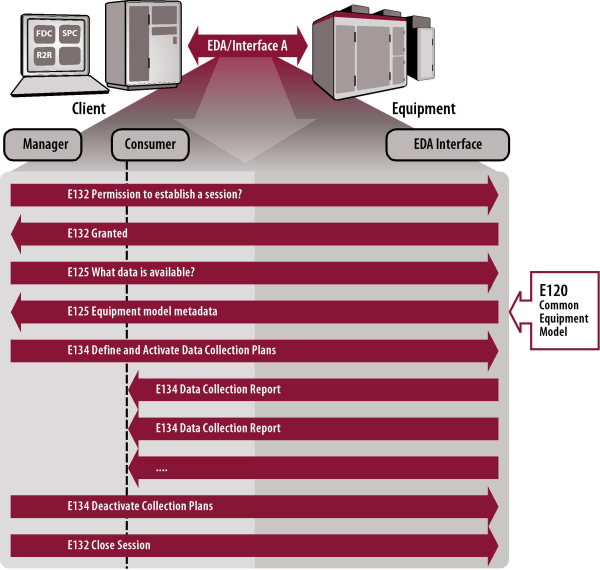

As companies see the improvements in quality and efficiency resulting from the investment in automation over the last decade, there is a greater focus on gathering and analyzing factory data and turning it into actionable information. The implementation of the Equipment Data Acquisition (EDA)/Interface A standards will now allow the industry to further improve the efficiencies in the automated manufacturing facilities by providing access to large quantities of process data.

SEMI (www.semi.org) released the EDA standards in 2005 in order to support the communication between the factory’s data gathering software applications and the factory equipment.

There was no intention of replacing other standards, such as SECS/GEM or GEM 300, and, in fact, EDA does not provide any features for equipment control or configuration. Instead, the EDA standards focus on gathering more data–—particularly state information, sensor feedback, actuator states, and other raw data– necessary for process, product and equipment analysis.

During 2005, IC makers started requiring integrated EDA solutions from the equipment suppliers. Since then, the demand has continued to increase as IC makers roll out plans to improve yield and equipment utilization. Some of the reasons EDA is gaining in popularity are:

- EDA supports multiple concurrent clients. SECS/GEM, on the other hand, supports only one client connection, which means semiconductor fabs cannot run several data gathering applications at the same time without an infrastructure to share the data.

- EDA presents the data in a hierarchy, organized by the major hardware components. By comparison, SECS/GEM data is relatively flat and unorganized, which means that the fab must study the documentation, hardware, software, and processing in order to understand how to organize the data.

- While data in a SECS/GEM message is highly structured and relatively inflexible, EDA standards use XML, which is inherently designed to accommodate additional metadata

- SOAP/XML and HTTP are the backbone of most Internet and Intranet applications and there are many programmers worldwide familiar with this technology. On the other hand, only a few industries use SECS/GEM, which limits the worldwide expertise.

There have been developments in EDA/Interface A standards since their introduction. The industry adopted the initial ISMI 1105 freeze version in 2006, and then, four years later, ISMI announced a new 0710 freeze version that includes many improvements and some new capabilities. Cimetrix has learned that equipment suppliers and semiconductor fabs need to discuss and agree upon which freeze version – whether it is 1105 or 0710 – that will be used both for the equipment and the host. In addition, they need to ensure there is a clear understanding of the acceptance testing for the interface.

For more information about the SEMI EDA/Interface A standards, we recommend you request the white paper at Cimetrix Introduction to SEMI EDA/Interface A Standards.

Maybe in a few years we will look back and smile at how common place EDA has become!