I had the privilege of speaking at the annual Advanced Process Control and Manufacturing (APCM) Europe conference in April of this year. The conference supports manufacturers, suppliers and scientific community of semiconductor, photovoltaic, LED, flat panel, MEMS, and other related industries. The topics are focused on current challenges and future needs of Advanced Process Control and Manufacturing Effectiveness. The theme of this year’s conference was From Reactive to Predictive - from SPC to Model-Based Process Control.

My presentation was entitled Fingerprinting and FDC: First Cousins in the Equipment Productivity Family. One of the areas I covered in that presentation was how the whole concept of fingerprinting came about.

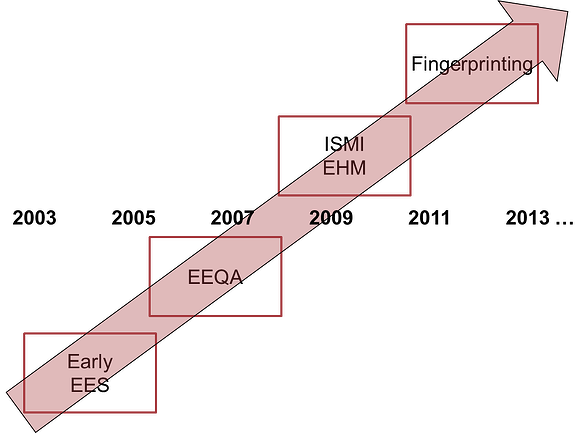

I’ve written about Equipment Health Monitoring, also known as fingerprinting, previously – see my blog post about Fingerprinting at SEMICON West at SEMICON West Follow Up: ISMI Fingerprinting Project. While the term fingerprinting has only recently been applied to this technology, the use of this type of application goes back a decade to the advent of Equipment Engineering Systems (EES), when the first major implementation of that technology was in the Renesas factory in Naka, Japan.

The basic idea was that semiconductor manufacturers could learn a great deal by collecting detailed trace and event information from the equipment to understand the behavior of low-level mechanisms, with the assumption that if the low-level mechanisms were exhibiting proper behaviors, then the entire machine would be operating within its specifications. This is the fundamental idea behind fingerprinting.

Back in 2003, when Renesas was implementing their EES program, there were no good standards for collecting low-level, high-speed trace information, and so the Renesas engineers expended a great deal of effort generating custom interfaces to collect trace and event data they could then feed into a common database. However, as they pursued the effort, they showed what kinds of analysis of the collected data could give them insight into the performance of their fab’s equipment.

As this idea gained traction, Shigeru Kobayashi one of the industry thought leaders at Renesas, proposed through the ITRS and SEMATECH to create a program around the idea of using detailed trace information to improve the equipment quality over time. This suggestion triggered the inception of the EEQA (Enhanced Equipment Quality Assurance) program.

The basic idea of the EEQA program, as it was with EES, was to collect low-level trace information about equipment mechanisms. That data could be shared with the equipment suppliers to show them how the equipment was operating in a production situation in order to improve the design and performance of the machines over time.

The EEQA program lasted more than 3 years at ISMI. There were a number of studies regarding the specific information that equipment engineers and fab engineers could use to characterize different equipment mechanisms and components. There were even a couple of prototypes developed to show how that information could be collected, modeled, and visualized and reported. However, the structural problem with the program was that it placed expectations on the OEMs regarding the amount of data that would need to be collected (and the effort involved in enabling this) without clearly showing the benefit to these suppliers. Consequently, the EEQA program lost support and lay fallow for a while.

However, the basic ideas of EEQA were preserved and folded into a subsequent SEMATECH umbrella program called equipment health monitoring (EHM). However, the energy for the program happened when someone attached an intuitive label to this notion of characterizing a component with its raw data. People attached the term “fingerprint” to that basic model, and the idea of grouping these trace values into a fingerprinting model that would have a specific value that manufacturing can track over time made the basic idea easier to understand and support. When EEQA was re-characterized and re-labeled as fingerprinting, the concept, and understanding the benefit that accrues from collecting and analyzing low-level trace data, finally took hold.

There was one other vital step necessary for the program to catch on in people’s minds. Equipment suppliers and fabs realized that to do predictive maintenance, as well as other health monitoring activities, they needed the data that they could collect using fingerprinting. With the basic concept of a fingerprint understood, and the recognition of the real value that collecting and analyzing the data would provide, both the equipment suppliers and the semiconductor manufacturers began to recognize the need for Equipment Health Monitoring, or fingerprinting.

The key component of any successful fingerprinting program is in-depth equipment domain knowledge, whether that comes from the OEM or from extensive use of that equipment at a specific fab. The OEM is the best official source, but the program can be initiated by the end user as well.

I will discuss more about the presentation at APCM Europe in my next blog post. Stay tuned.